-

Ti-6Al-4V, also termed as TC4, titanium grade 5 and grade 23 (extra low interstitials), is the most commonly used Ti alloy1,2. It combines excellent properties including good mechanical performance, outstanding corrosion resistance, and superior biocompatibility. Therefore, Ti-6Al-4V is widely applied in aerospace, automotive, marine and chemical industries. Furthermore, it has been widely used in biomechanical applications such as implants and prostheses1–3. The details of the Ti-6Al-4V powders are available in the ASTM and AMS specifications4,5.

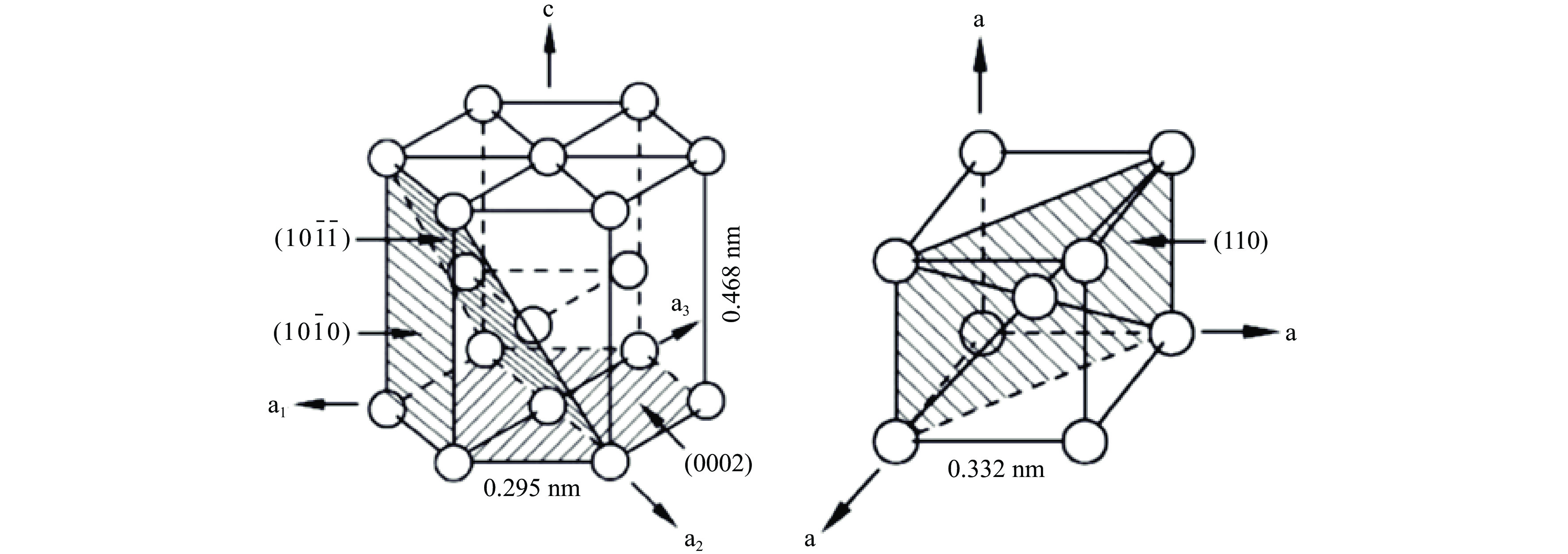

Ti-6Al-4V is an α+β titanium alloy with a hexagonal close packed (HCP) α phase stable at low temperatures, and a body centered cubic (BCC) β phase stable at high temperatures1. The β/α allotropic transformation temperature (β transus) is approximately 995 °C for Ti-6Al-4V2, and this temperature can be increased by adding α stabilizers (Al, O, N, and C) and decreased by alloying with β stabilizers (V, Mo, Fe, etc.)1,2. The crystal structures of α and β phases are shown in Fig. 1. Similar to another HCP/BCC metal Zr6, the crystallographic orientation relationship between HCP Ti (α) and BCC Ti (β) obeys the Burgers orientation relationship for which

$ \left\{0001\right\} $ α//$ \left\{110\right\} $ β and <$ 11\overline {2}0 $ >α//<$ 111 $ >β1.

Fig. 1 Crystal structures of HCP α and BCC β phases in titanium1.

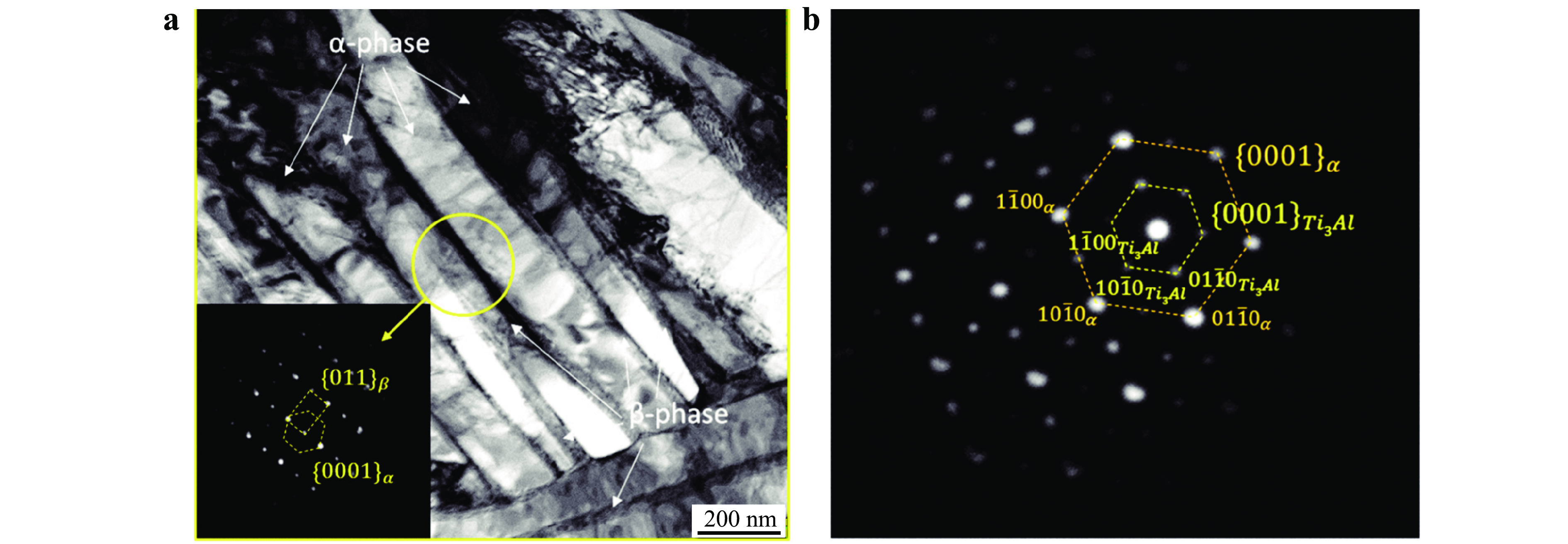

In Al-containing Ti alloys, the precipitation of ordered and coherent Ti3Al (α2) phase can occur in α grains after ageing at low temperatures of approximately 500 °C when the Al content is at 6 wt.%7–9. Specifically, α2 has a hexagonal D019 superlattice structure1, in which the lattice parameter on the basal plane is twice that of α phase, whereas the lattice parameter remains the same on the c-axis. The α2 solvus temperature is approximately 550 °C for Ti-6Al-4V1. Similar to the influence on β transus, Al and O are α2 stabilizers, which extend α+α2 phase field to higher temperatures and promote the ordering transformation. Ordered α2 phase introduces precipitation hardening, and it is an extremely brittle intermetallic phase1,2. The presence of α2 results in non-homogeneous planar slip, and increases the effective slip length and strain localization10,11, which has detrimental effects on microcrack propagation, low cycle fatigue (LCF) resistance, and stress corrosion cracking resistance1,12.

Rapid cooling from temperatures above the martensitic start temperature (Ms) leads to diffusionless transformation. The martensite start temperature (Ms) in Ti-6Al-4V has been reported in a wide temperature range from 575 °C to 800 °C13–15, and a lower Ms has been observed at a higher cooling rate15. Similar to β transus and α2 solvus temperatures, the martensitic start temperature is affected by the alloying elements. In general, the metastable martensite is hexagonal α’ in Ti-6Al-4V, and the Burgers orientation relationship is still valid between β and α’1. Given that the interstitial O atoms only introduce a small elastic distortion in α’ martensite, the martensitic hardening leads to a slight increase in strength. Orthorhombic α’’ martensite is rarely observed in the low V containing Ti-6Al-4V. The martensite type can be determined by the temperatures from which Ti-6Al-4V is quenched and the concentration of β stabilizers in the β phase at that temperature3. In the α+β phase field, the V concentration in β is dependent on the temperature. The formation of α’’ is observed under conditions with a V concentration exceeding 9 wt.%1,3. For example, the β phase is enriched with V concentration of up to 10 wt.% at a temperature range of 800−850 °C, and water quenching (WQ) from this temperature range leads to α’’ martensite transformation16. In contrast to the hardening effect of HCP α’ martensite, the orthorhombic α’’ martensite is soft and can provide deformability2,3. Both metastable α’ and α’’ martensite phases can decompose into equilibrium α and β phases at suitable heat treatment temperatures.

The high cost of conventionally processed Ti alloys limits their applications, and crucial contributors to the expense are the significant material wastage, high energy input, and long lead times in conventional processing techniques17. Laser powder bed fusion (LPBF), as an advanced additive manufacturing (AM) technology, has attracted significant attention and has been implemented in research and industry over the last two decades. It has a wide range of advantages such as producing nearly fully dense and complex shaped components at a high resolution (which cannot be realized via conventional methods), high material utilization with limited machining, and reduced lead times18,19.

Specifically, LPBF is a complicated metallurgical process, which involves powder melting and extremely fast directional solidification, re-melting and re-solidification during the subsequent scan tracks and layers, and post-solidification thermal cycling. The understanding of microstructure evolution during the LPBF process and post-process treatment is essential to obtain Ti-6Al-4V components with high quality and satisfied properties. In this review, the LPBF technique and its processing parameters are briefly introduced. Then, the possible types of defects, residual stress, and LPBF built surface are reviewed. Subsequently, the unique as-fabricated microstructure and microstructure evolution during the post-process treatment are summarized, and its effects on tensile, fatigue, fracture toughness, and creep properties are discussed.

-

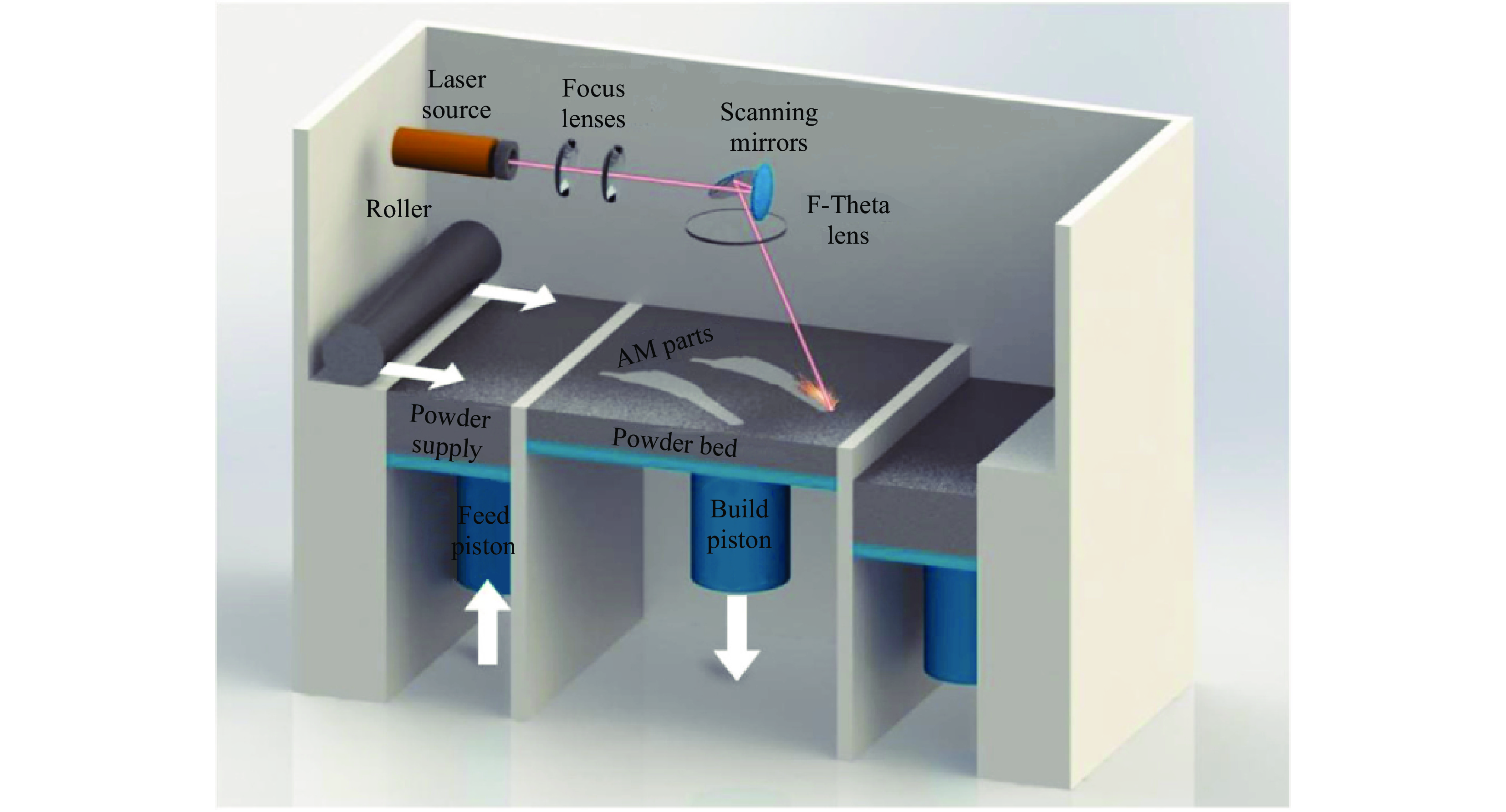

LPBF, also known as selective laser melting (SLM) or direct metal laser melting (DMLM), was developed in the Fraunhofer Institute ILT in 199520. It employs a focused laser beam to melt metallic powders within a selected area based on the cross-sectional slice of a 3-dimensional (3D) CAD model, and the melt pool is then solidified at a high cooling rate. After a layer has been scanned, the build platform is lowered by a depth, which is defined as the layer thickness. A new layer of powder is spread by the re-coater and melted by the focused laser beam based on the next cross-sectional slice. The layer-by-layer deposition is repeated in a protective atmosphere until all the slices of the CAD profiles are complete. Fig. 2 illustrates a typical LPBF system, which includes a processing laser, an automatic powder feed and overflow system, and an inert gas protection system21,22. After fabrication, unused powders can be collected from the overflow and powder bed. These collected powders can then be recycled and reused23,24.

Fig. 2 Schematic diagram of a typical LPBF system24.

-

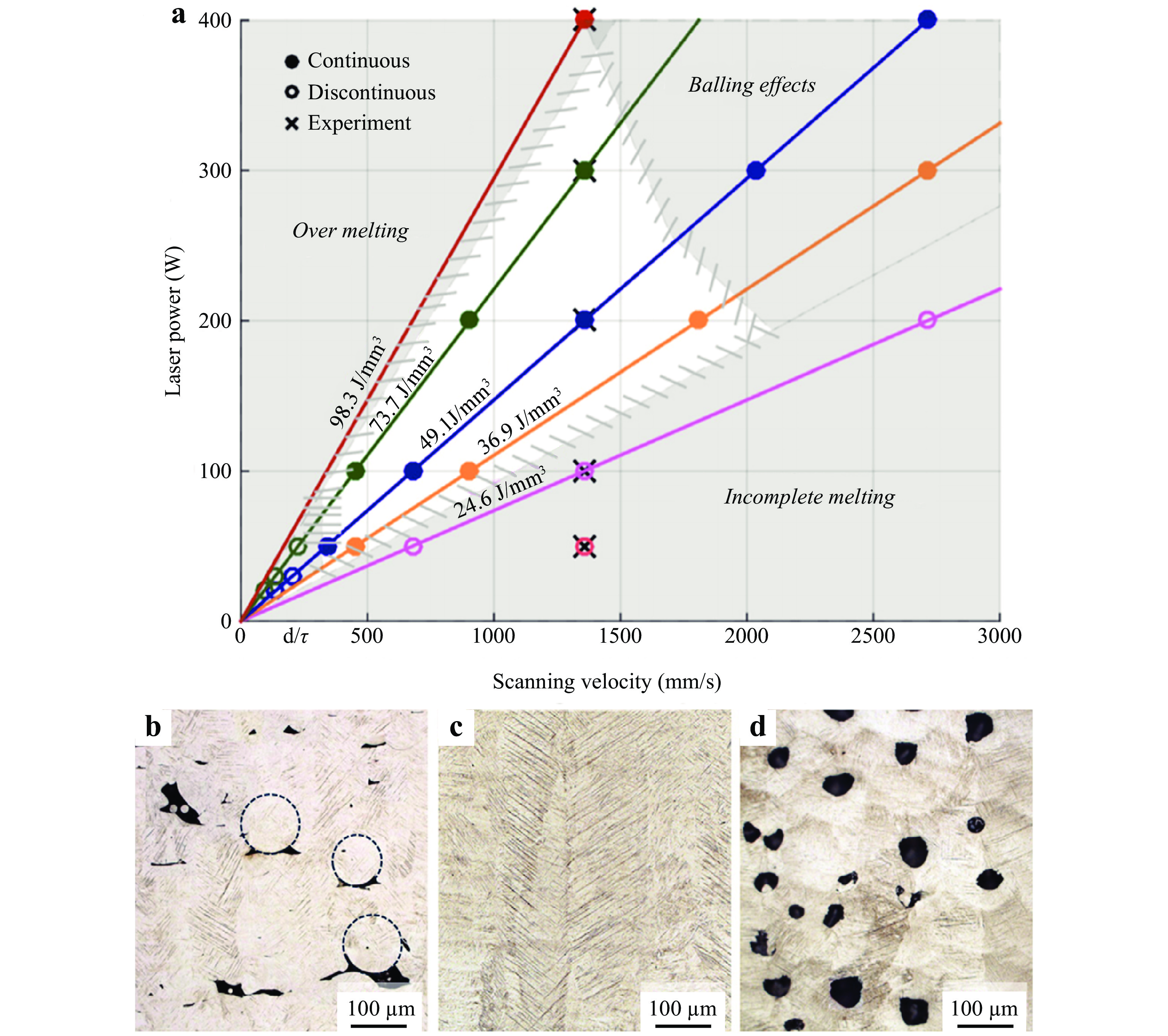

The main in-process parameters include laser power, laser spot size, scanning speed, hatch distance, layer thickness, and build platform pre-heating temperature. Among them, the most widely manipulated parameters are laser power and scan speed. Fig. 3a presents a processing window between these two parameters. A high laser powder and a low scan speed can introduce an excessive energy input, which can lead to liquid melt overheating, evaporation within the melt pool, and keyhole defects25. Conversely, a low laser power and a high scan speed can lead to insufficient energy density, which causes incomplete melting, inadequate penetration and lack-of-fusion defects24,26,27. In addition to laser power and scan speed, inappropriate hatch distance and layer thickness can also result in lack-of-fusion defects. Furthermore, balling can occur at high laser power and scan speeds even for a suitable energy density as shown in the top right corner of Fig. 3a28,29. Given that the increased laser power leads to a higher boosting effect on the maximum temperature achieved in the melt pool than the reverse effect from the increased scan speed30,31, a higher peak melt pool temperature induces a more intense Marangoni flow, which can cause the Plateau-Rayleigh instability and balling30,32,36. An example of different types of defects in LPBF fabricated Ti-6Al-4V is illustrated in Fig. 3b−d. For an intermediate laser power of 175 W, gradually decreasing scan speeds are located in the three different regions of incomplete melting, processing window, and overheating as shown in Fig. 3a. Additionally, another type of defect is gas porosity, which is typically small in size33. The formation of gas pores can be related to two main causes: (a) the inert gas pores trapped within the powder feedstock during the powder atomization process are transferred to the part34, and (b) after solidification, the protective gas can be trapped in the melt pool as bubbles due to the rapid cooling in LPBF fabrication35.

Fig. 3 A process window and various types of defects in LPBF fabricated Ti-6Al-4V.

a A processing window for LPBF fabricated Ti-6Al-4V28. b−d The influence of scan speed on porosity types in LPBF fabricated Ti-6Al-4V with a fixed laser power of 175 W and a hatch distance of 100 µm36. b Lack-of-fusion due to insufficient penetration at a high scan speed. c A nearly fully dense microstructure density at an intermediate scan speed. d Keyhole type defects due to overheating at a low scan speed. -

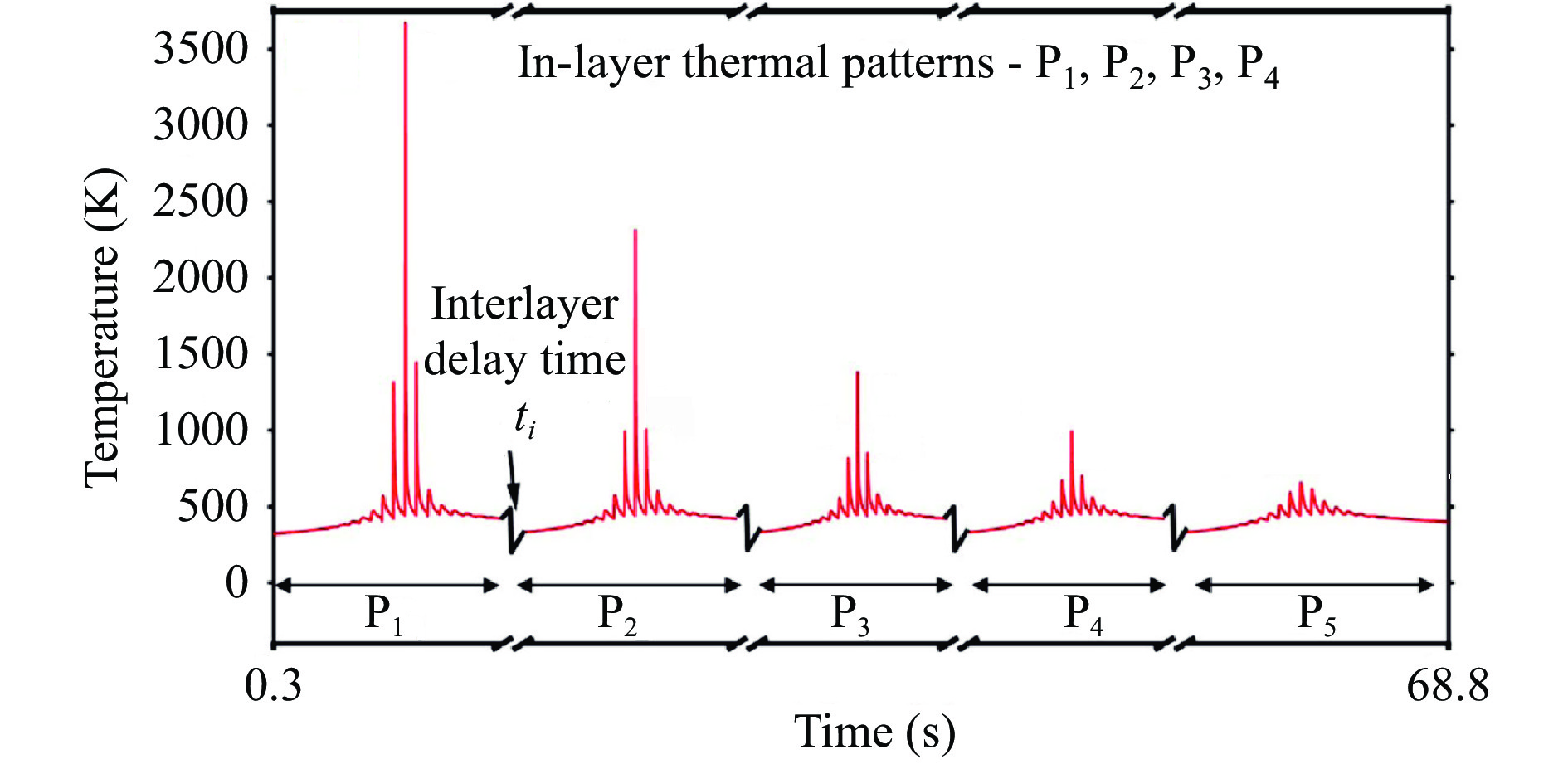

LPBF exhibits a unique thermal history including directional melting-solidifying against the heat transfer direction, subsequent re-melting/re-solidifying due to the following laser scan and deposited layer, and post-solidification cyclic heating/cooling37–39. Fig. 4 is a simulated thermal history of a given location in a LPBF fabricated Ti-6Al-4V40, and there are thermal cycles from different laser scan vectors within a layer and thermal cycles in the following layers. After solidification from the peak temperature in layer P1, the material undergoes a series of thermal cycles in the following laser scan tracks and layers. When the next track is scanned or the next layer is deposited, the previously fabricated material can be partially re-melted and re-solidified. The combined effect of high laser power, fast laser scan speed, and small laser spot size leads to an extremely high heating and cooling rate41–44. According to an in-situ synchrotron experiment on LPBF fabricated Ti-6Al-4V, the maximum heating and cooling rates can reach the orders of 106 °C/s and 105 °C/s, respectively45.

Fig. 4 Simulated thermal cycling history of a specific location in LPBF fabricated Ti-6Al-4V.

This includes intralayer and interlayer reheating and cooling. P1 to P5 are different layers40. -

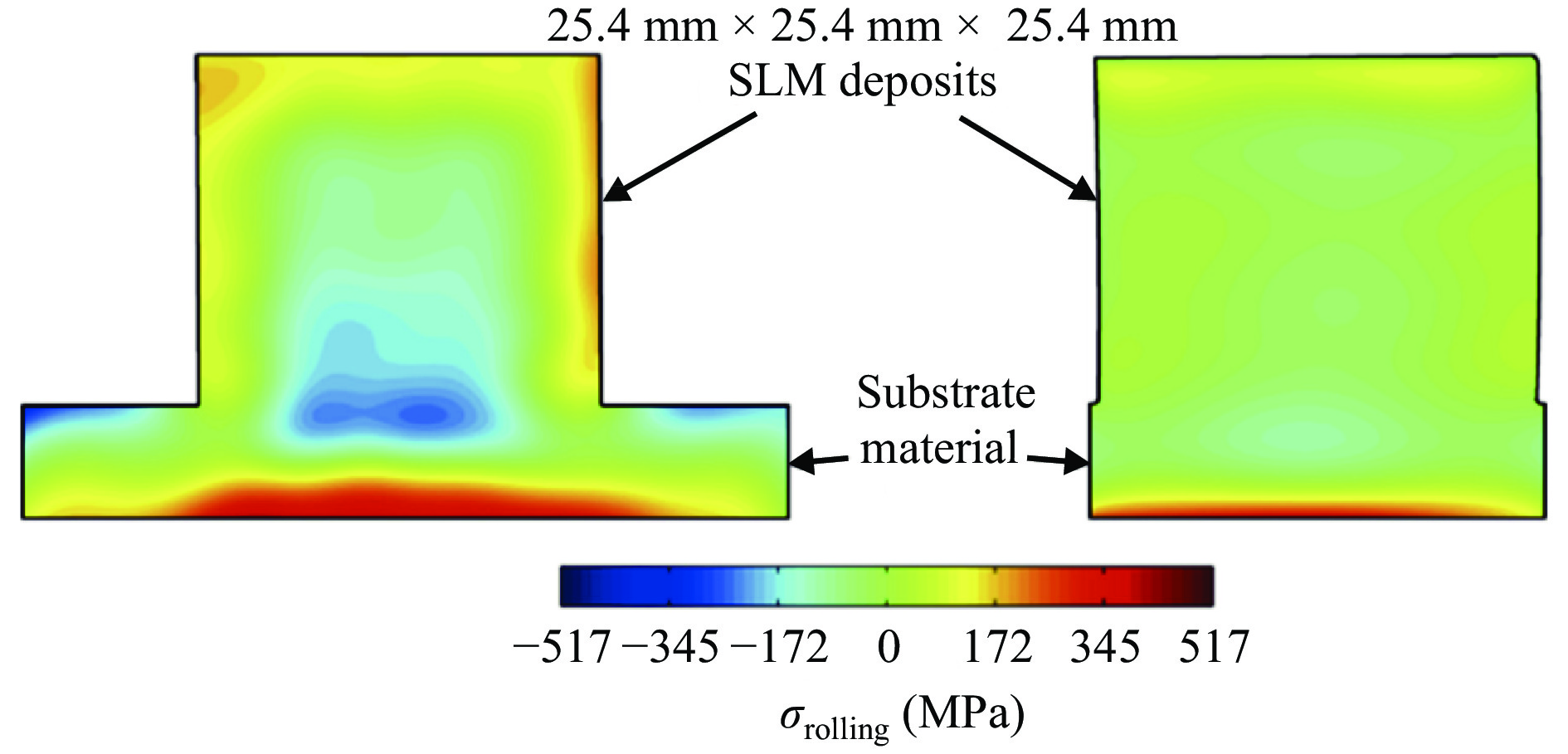

During LPBF fabrication, the high cooling rate and large thermal gradients lead to high levels of residual stress46. This can cause distortion and delamination, which results in parts failure and unacceptable dimensional change47,48. In general, residual stress varies with the build height. Fig. 5 shows the residual stress distribution in Ti-6Al-4V cuboids fabricated on large and small substrates measured by the contour method. Specifically, the tensile residual stress presents at the bottom of the substrate and top surface of the built sample with a large compressive stress region located in between according to simulations49 and experimental contour method50. In the horizontal cross-section, high tensile residual stress/strain is generally located at the part edge, while compressive residual stress is at the part center51. More specifically, the tensile residual stress can exceed 900 MPa at the part edge51, which is close to the yield strength of Ti-6Al-4V.

Fig. 5 Residual stress of LPBF fabricated Ti-6Al-4V measured via contour-method in the rolling direction of the substrate.

Specimens are built on a large substrate with an overhang (left) and a small substrate without an overhang (right)50.Tensile residual stress is deleterious to fatigue properties, because it tends to facilitate fatigue crack propagation3. In addition to the influence on fatigue, the parts removal from substrate without stress-relieving heat treatment would introduce deformation through strain/stress relaxation46,49. Therefore, efforts have been made to reduce the residual stress, including substrate heating during the LPBF process and post-process stress-relieving heat treatment. Furthermore, residual stress can be influenced by the in-process laser scan strategy and scan rotation between neighboring layers. A lower residuals stress was observed in the bi-directional scan than that resulting from a chessboard scan. Additionally, a scan rotation of 90° led to a reduced residual stress when compared with that in a scan rotation of 67°52.

-

The surface roughness can be controlled by the powder particle morphology and size, layer thickness, processing parameters, scan strategies, and the orientation relationship between the inclined surface and laser incident direction53–58. In addition, the frequently used support structures adversely affect the surface finish of LPBF fabricated parts even after support removal59.

The surface of LPBF fabricated parts is covered by partially melted powder particles57. Hence, the powder characteristics affect the surface roughness. Given that LPBF is a layer-wise manufacturing process, a larger layer thickness leads to a rougher inclined surface owing to the staircase effect53,54,58. More importantly, laser processing parameters can influence the melt pool morphology30, which in turn affects the surface quality. A few studies employed contour scans to improve the quality of the as-fabricated surface56,58. Other factors, including the location of the part on the substrate, the orientation relationship between the inclined surface and the laser incident direction, have also been found to influence the surface roughness56.

Surface treatments after LPBF fabrication are generally applied to improve surface quality. The most commonly used treatments include blasting57, shot peening60, vibratory grinding/tribo-finishing57,60, machining/micro-machining18,57, and electropolishing60. The loosely attached powder particles on the surface of LPBF fabricated parts can be addressed by blasting and shot peening; however, the blasting and/or peening media can introduce deformations on the surface57; hence, they can only slightly reduce the surface roughness. In addition, shot peening results in work hardening and compressive residual stress in the surface layer, which prevent the fatigue crack initiation from the surface61. Vibratory grinding leads to a smoother surface, and it provides a better surface finish (Ra) of a few μm when compared with blasting and shot peening. Machining and electropolishing are effective methods to remove the surface layer, which contributes to the lowest surface finish (Ra) below 1 μm57,60.

-

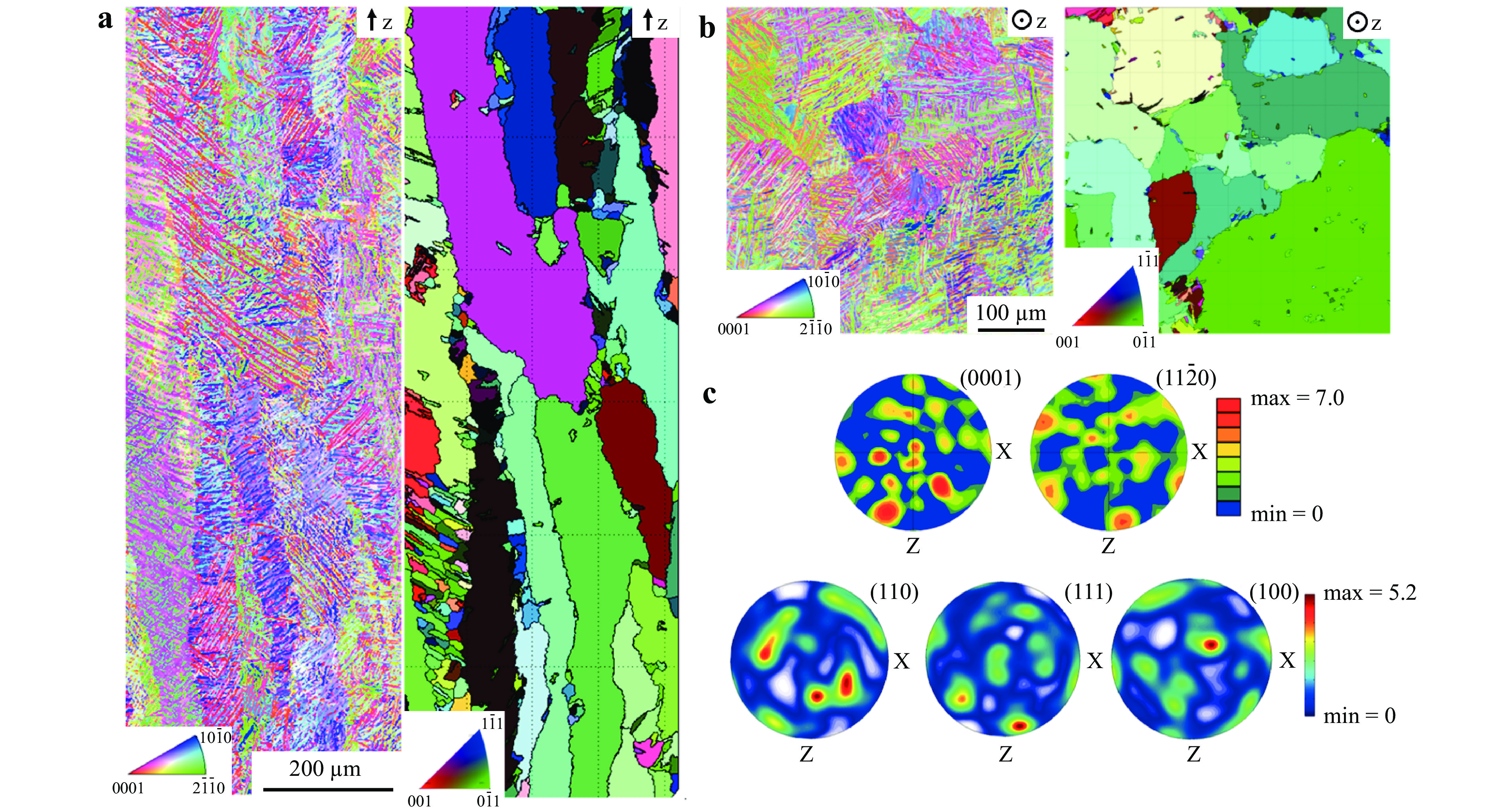

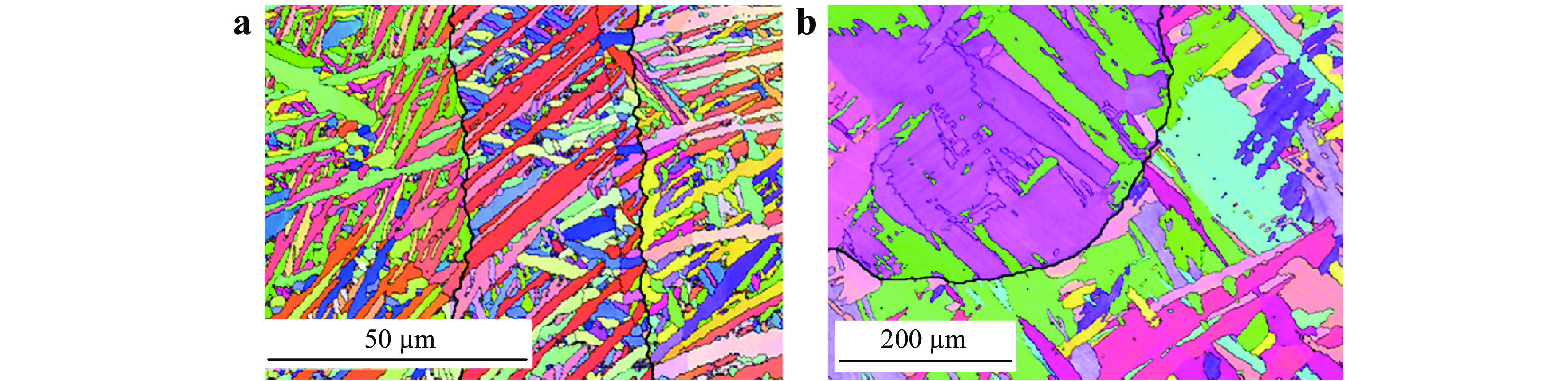

The directional solidification, rapid cooling after melting, and subsequent thermal cycling result in a non-equilibrium hierarchical as-fabricated microstructure of epitaxial grown prior-β grains aligned in the opposite direction of the cooling direction, and these columnar β grains consist of a few sets of fine acicular α’ martensite variants16,31,38,62–67. The processing parameters affect the as-fabricated microstructure. A recent study showed that a higher laser energy density leads to a larger prior-β grain width and a smaller α’ martensite size68. In addition to the columnar grains, the partial re-melting of the previously solidified layers leads to a strong β solidification texture. As shown in Fig. 6, a preferred {

$ 100 $ }β texture along the grain growth direction has been found on the BCC orientation map reconstructed from electron back-scatter diffraction (EBSD) data of HCP Ti (α and/or α’) based on the Burgers orientation relationship62,63. It is important to note that the β grain growth direction can be influenced by the thermal flux direction, which is affected by the laser scan speed and strategy38,62. As a result, the growth direction of β grain can be either parallel or inclined at a certain angle to the macroscopic build direction (Z)31,62. The pole figure in Fig. 6c is an example where the {$ 100 $ }β texture in the grain growth direction is inclined approximately 20° away from the build direction62.A few studies have shown that a small amount of β can be detected by synchrotron XRD69, EBSD70, and TEM71 in specimens fabricated at either high laser powers or short hatch distances. Fig. 7a shows an α+β microstructure at the middle height of a sample manufactured with a short hatch distance71. Both high laser power and short hatch distance can increase the in-process temperatures achieved and the time at high temperatures during the intrinsic thermal cycling45. These factors facilitate the deposition of metastable martensite into α+β phases. In addition to β, a few studies have reported α2 precipitates in the as-fabricated sample based on TEM and synchrotron XRD results38,71. Fig. 7b shows the superlattice reflection of α2 formed in α lamella, and the formation of α2 is believed to be related to the thermal cycling at temperatures just below the α2 solvus. Carefully controlled Al and O compositions in the Ti-6Al-4V powders and the low O concentration in the printing atmosphere can suppress the α2 precipitation.

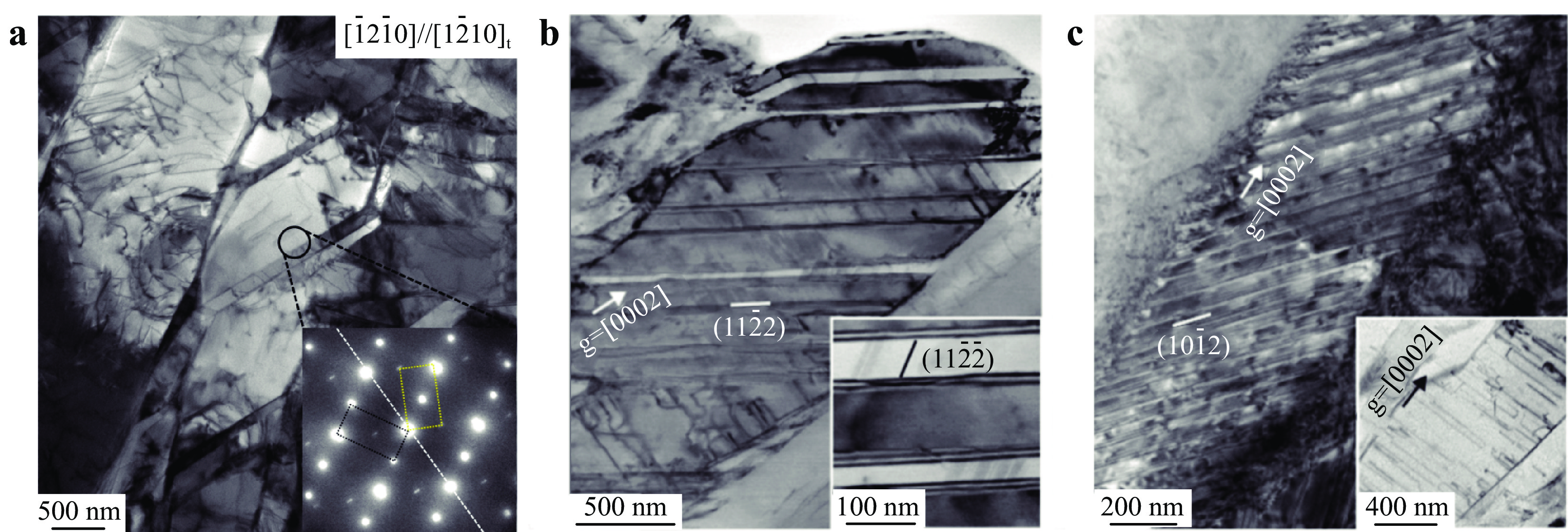

In general, the as-fabricated Ti-6Al-4V has a fully α’ martensitic microstructure. As a result of thermal cycles, α’ martensite has a hierarchical structure with different width and length, which can be identified as primary, secondary, tertiary and quartic α’, and their formation mechanism has been described in detail in a recent study72. Within the α’ martensite, lattice defects, including dislocations, stacking faults and twins, are present73,74. A high density of dislocations has been identified in α’ plate via TEM69 and diffraction peak broadening phenomenon in high energy XRD70. The TEM dislocation analysis (g·b test) revealed the presence of both <α> and <c+α> dislocations within martensite, which indicates that significant plastic deformation occurs during the LPBF process69.

In principle, {

$ 10\overline {1}1 $ }<$ 10\overline {1}\overline {2} $ > and {$ 11\overline {2}2 $ }<$ 11\overline {2}\overline {3} $ > twins can be activated when compression is applied along the c-axis, while {$ 10\overline {1}2 $ }<$ 10\overline {1}\overline {1} $ > and {$ 11\overline {2}1 $ }<$ 11\overline {2}\overline {6} $ > twins can occur when tension is applied along the c-axis for HCP titanium75. In LPBF fabricated Ti-6Al-4V, compression {$ 10\overline {1}1 $ }76,77 and {$ 11\overline {2}2 $ } twins69, and tension {$ 10\overline {1}2 $ }69,72,78,79 twins have been reported in hexagonal α’ martensite as shown in Fig. 8. A previous work has suggested that tension {$ 10\overline {1}2 $ } twins can accommodate the tensile residual stress at the top region of LPBF fabricated parts79, but this does not explain the co-existing compression and tension twins in the same TEM sample. Some studies have shown that twinning is related to the martensitic transformation of β→α’76,80. However, this can only explain the activation of$ \left\{10\overline {1}1\right\} $ twins. A recent study has proposed that thermal cycles of fast heating to and rapid cooling from different peak temperatures and associated solid state phase transformation can lead to the formation of both compression and tension twins in LPBF fabricated Ti-6Al-4V81.In addition to hexagonal α’ martensite, orthorhombic martensite α’’ has been reported in as-fabricated Ti-6Al-4V in a few studies66,77,78. For samples fabricated at the same LPBF parameters, α’’ was observed in one of the Ti-6Al-4V cuboids with a larger horizontal (X-Y) cross section area. The results suggested that faster cooling related to the larger heat conduction area on the horizontal cross section could lead to α’’ formation77. However, the discussion is missing regarding the influence of horizontal cross-sectional area on the temperature achieved during the post-solidification thermal cycling. During LPBF, thermal cycling can heat some previously deposited layers to intermediate temperatures in the α+β phase field. At these temperatures, element segregation occurs and β phase is enriched in V. Thus, rapid cooling from such temperatures would result in the formation of α’’ martensite78.

When compared to thermo-mechanically processed Ti-6Al-4V, as-fabricated LPBF Ti-6Al-4V exhibits higher strength but lower ductility due to the non-equilibrium α’ martensitic microstructure64,65,72,82 and residual stress built up during the LPBF process83,84. As a result, in-process measures and post-process treatments have been explored to promote the metastable martensite decomposition to equilibrium α+β phases and to minimize residual stress.

-

During the LPBF process, a preheated substrate generally reduces the temperature gradients within the parts and decreases residual stress85. Substrates preheated to 370 °C and 570 °C can effectively reduce the residue stress by 71% and almost 100%, respectively, when compared to the sample built on a substrate heated to 100 °C86. For LPBF fabricated α’ martensite, TEM and in-situ XRD investigations revealed that martensite decomposition commences at a low temperature at 400 °C87. β phase has been observed in the as-deposited Ti-6Al-4V fabricated on a preheated substrate at 200 °C and with a tight hatch distance of 40 µm71. A substrate preheated at 500 °C results in a partially decomposed α’ martensite microstructure16, which improves elongation to approximately 10%86. However, high temperature preheating is not energy efficient, and can account for 40% of the total energy consumed in LPBF fabrication88. In addition, in a recent study, it was indicated that a preheated substrate at 550 °C leads to significant oxidation89, because titanium suffers a high chemical affinity to oxygen at high temperatures. High oxygen content contributes two consequences, namely increased brittleness and deteriorated powder recyclability90,91.

Other in-process measures, including manipulation of laser beam focal offset distance (FOD) and interlayer time, were used to increase the temperature achieved during the intrinsic thermal cycling and to promote the α’ martensitic decomposition92. Specifically, FOD can control the laser spot diameter and the local applied energy within the laser beam93, and an increased FOD generally leads to a decreased temperature and a shortened time window for in-situ martensite decomposition during the intrinsic thermal cycling94. Given that LPBF is a layer-by-layer deposition process, a short interlayer time of less than 12 s have been found to be effective in promoting the in-process martensite decomposition, which leads to a coarser α+β lamellar microstructure95,96. With a suitable FOD of 2 mm, an ultrafine fine α+β lamellar microstructure has been achieved in the as-deposited Ti-6Al-4V fabricated on support structures with a substrate preheated at 200 °C64. In addition to the FOD manipulation, all the aforementioned investigations included lattice support structures to decrease the amount of heat transferred to the substrate, thereby increasing the in-situ thermal cycling temperature. Support structures are known to introduce surface roughness even after support removal59, which affect the as-built surface quality and its application in the as-built condition.

-

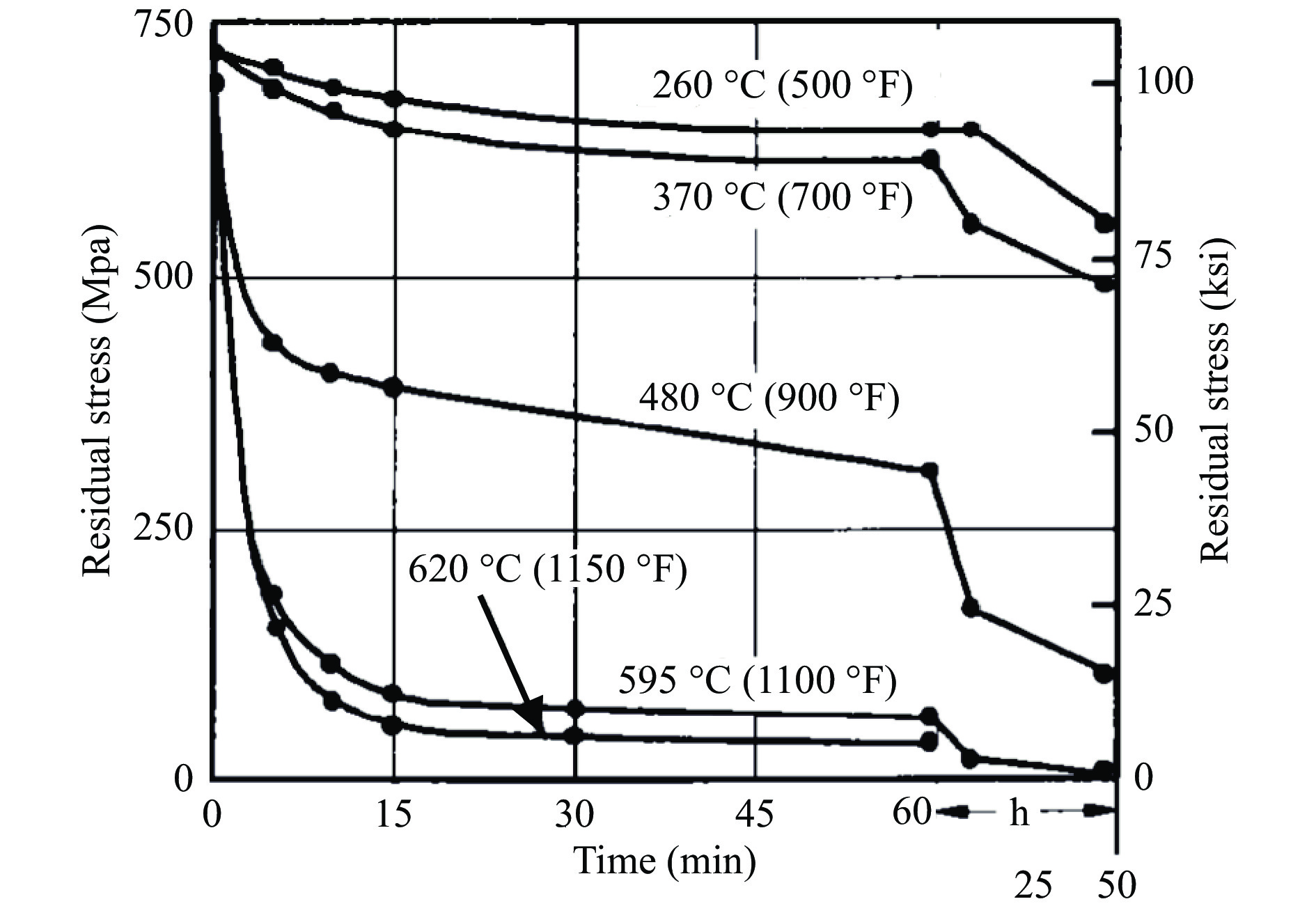

In general, stress-relieving treatments are carried out in the temperatures between 450 °C and 650 °C followed by air cool (AC) or furnace cool (FC) prior to the electrical discharge machining (EDM)3,97. For instance, a 2−4 h stress-relieving treatment at 595 °C followed by AC is recommended for Ti-6Al-4V weldment3. Such a heat treatment is generally performed in a protective argon atmosphere, which reduces oxidation and the formation of α case. As shown in Fig. 9, the time required for stress relief is dependent on temperature. A higher stress-relieving temperature decreases the required heat treatment time. For example, 1 h at 595 °C is equivalent to 5 h at 540 °C in terms of stress relief effectiveness3. As the stress-relieving temperature is relatively low in the α+β field, the as-deposited microstructure will be slightly coarsened although the size and variants of primary and secondary α/α’ laths are maintained98.

Fig. 9 Effect of stress-relieving temperatures on residual stress in Ti-6Al-4V3.

It should be noted that the α2 solvus temperature is approximately 550 °C for Ti-6Al-4V1, and it can be influenced by the Al and O content. A stress-relieving temperature below the α2 solvus can lead to the precipitation hardening of α phase by α2 particles73, which is dependent on the Al and O concentration in the α phase. If the LPBF fabricated parts are used after stress relief, the stress-relieving temperature should be cautiously determined by whether α2 formation is ideal for the application.

-

It is widely accepted that the α’ martensite formed in LPBF is brittle and responsible for the low elongation below 10% in the as-fabricated Ti-6Al-4V31,64,70,78,83,84,96. Such a low ductility does not satisfy the elongation requirement of 10% as per the specification of AM fabricated Ti-6Al-4V in ASTM 2924–144. Therefore, investigations have been focused on promoting the non-equilibrium α’ martensite decomposition in the as-fabricated microstructure to an equilibrium α+β microstructure through annealing. Previous studies have revealed that annealing in the range of 750-900 °C can effectively facilitate the α’ martensite decomposition and improve the ductility76,99,100.

When compared with the stress-relieving heat treatments, annealing is generally performed at relatively higher temperatures in the α+β phase field and followed by AC or FC97. A direct annealing can promote martensite decomposition into α and β phases, and the lamellar microstructure will be significantly coarser than the as-fabricated microstructure. A recent study has explicitly investigated the static coarsening behavior of lamellar structures in LPBF fabricated Ti-6Al-4V, which suggests that heat treatment temperatures at 900 °C or higher significantly accelerate the coarsening kinetics101.

-

In thermomechanically processed titanium alloys, solution treating and aging (STA) treatments are generally used to improve strength. Such a heat treatment has also been employed as a post-process treatment for LPBF fabricated Ti-6Al-4V, which can be categorized into β STA and α+β STA based on the solution temperature. As shown in Fig. 10, the β STA microstructure has significantly coarsened prior-β grains when heat treated at temperatures above the β transus, and β grains lose the columnar morphology on vertical plane84,102. Because all the α’/α lamellae transform to β phase solid solution at such temperatures, and β grains begin to grow84. For example, a β solution treatment at 1015 °C for 2 h led to an increase in β grain width with unchanged length84, and a heat treatment of 2 h at 1050 °C resulted in equiaxed prior β grains in LPBF fabricated Ti-6Al-4V102. The width of α lamellae is related to the cooling rate after β solution treatment. After the β STA, there are fewer α variants left. This results in increased α colony size, which leads to a longer effective slip length for dislocations.

When compared to β STA, α+β STA is versatile in terms of achieving different microstructures, in which the size, volume fraction, and morphology of various phases can be manipulated. A 2 h α+β solution treatment followed by a slow cooling method, such as FC, generally leads to an α+β lamellar microstructure, and a small amount of equiaxed α can form at solution temperatures close to β transus102,103. If fast cooling methods such as AC or WQ are used, some β phases can transform to fine αs (secondary α) or martensitic microstructure during cooling. Several studies have indicated that a bi-modal microstructure can be obtained in LPBF fabricated Ti-6Al-4V through post-process α+β STA treatments102,104,105. In addition to LPBF, the bi-modal microstructure has been reported in similar post-process sub-transus STA treated Ti-6Al-4V fabricated by other AM techniques including electron beam melting (EBM)106, direct laser deposition (DLD)107, and wire arc additive manufacturing (WAAM)108.

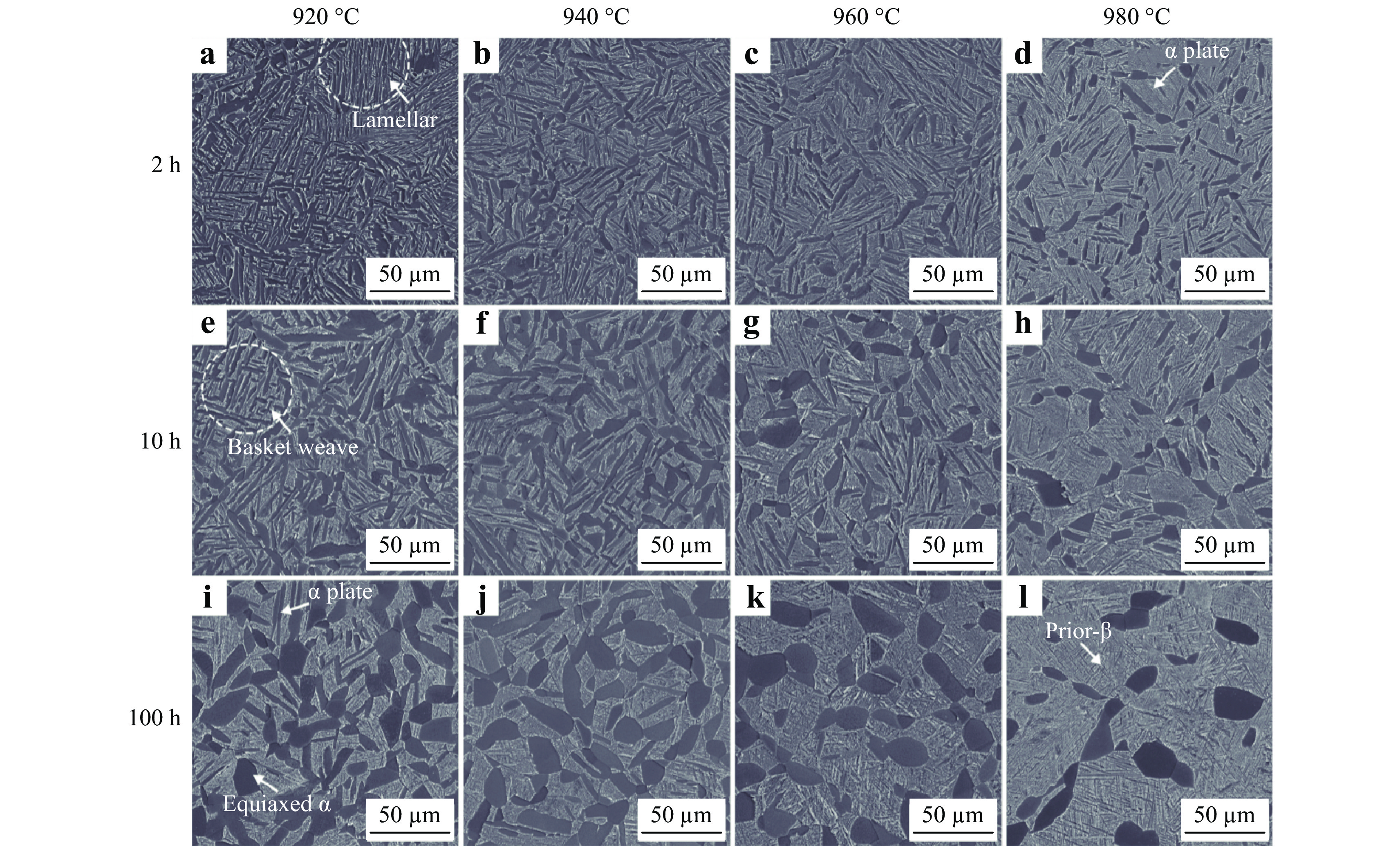

As show in Fig. 11a, the microstructure is still mainly α+β lamellae for low to intermediate solution temperatures of up to 920 °C for 2 h followed by AC. This is due to the low equilibrium volume fraction of β phase when the solution temperature is exceedingly below the β transus, and the relatively slow AC used after solution treatment. Fig. 11b−d show that increases in solution temperatures lead to an increased βt (transformed β) region, in which fine αs precipitates are formed. In the meantime, the volume fraction of αp (primary α) decreases, and the aspect ratio of αp decreases with the formation of some equiaxed αp grains. Fig. 11 also presents the influence of solution time, and a longer solution time results in a reduced number density of αp, a larger sized αp and a more globular αp morphology.

Fig. 11 Effect of sub-transus solution temperature and time on microstructure.

SEM images of LPBF fabricated Ti-6Al-4V after different α+β STA heat treatments. The results show the effect of solution temperature and time on the microstructure evolution; all the solution treatments are followed by AC and a subsequent aging treatment at 700 °C/2 h/FC105.In general, plastic deformation prior to heat treatment is essential for inducing globularization in thermomechanically processed Ti-6Al-4V. While in LPBF fabricated Ti-6Al-4V, plastic deformation is not required for the globularization to occur. Because the high dislocation density inherited from the LPBF process can initiate the globularization. The globularization mechanism is similar for LPBF fabricated and thermomechanically processed Ti-6Al-4V. Tangled dislocations in α’ martensite can rearrange into dislocation arrays and form sub-grain boundaries during the α+β solution treatment107. In the initial stage of globularization, dislocation arrays and sub-grain boundaries are the feasible locations for the boundary splitting process, which includes the growth of β phase into the sub-grain boundary (thermal grooving) and edge spheroidization at lamellae ends109. For a prolonged solution treatment, the globularization is driven by the second mechanism related to the α lamellae coarsening by termination migration consisting of mass transfer from curved surface to flat surfaces. This results in shorter and thicker αp lamellae, which gradually change the lamellar morphology to a more equiaxed morphology109.

In addition to α+β STA, a recent study has reported that a sub-transus cyclic heat treatment between 975 °C and 875 °C with slow heating and cooling rates for 24 h is able to provide a bi-modal microstructure with coarse globularized αp and fine αs within the βt region110. The globularization mechanism during cyclic heat treatment differs from that mentioned in the α+β STA. The cyclic heat treatment leads to variations in the volume fraction of α and β, which promote α lamellae to β transformation in the heating cycle and facilitates β to a more equiaxed α transformation during the slow cooling cycle. During the heating cycle, the transformation from α to β also stimulates faster thermal grooving and boundary splitting processes110.

-

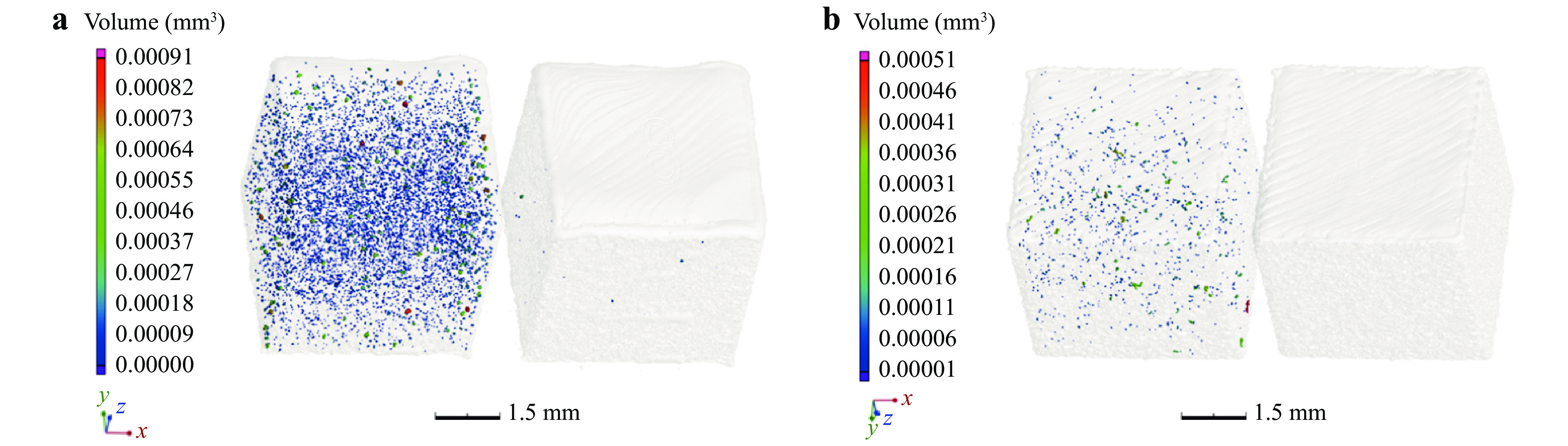

Typically, LPBF fabricated metals and alloys often contain defects such as gas pores, contour related pores, lack-of-fusion, keyhole pores, and partially melted powders25,31,38,111. These defects are detrimental to the fatigue properties and can affect the quality control of the LPBF process. As shown in Fig. 12, hot isostatic pressing (HIP) is an effective post-process method for tackling defects, including lack-of-fusion, keyhole, and gas pores, but it does not address pores connected to the surface as indicated by a few defects retained after HIP in Fig. 12a. Similar evidence of pore closure in HIP have been reported in other studies112,113. In addition, HIP can consolidate partially melted or unmelted powders111. A few studies have revealed that post-HIP annealing, including both sub-transus and super-transus heat treatments, re-opens the HIP ‘closed’ pores111,114,115. This indicates that these defects, containing Ar gas, are not eliminated by HIP and instead converted into small high-pressured pores, which are below the resolution of X-ray tomography.

Fig. 12 Effect of HIP treatment on defects closure in LPBF fabricated Ti-6Al-4V.

a Keyhole and gas pores closed by HIP. b Lack-of-fusion and gas pores closed by HIP. The voxel size is 5 µm for the X-ray tomography experiment111.The microstructure evolution during HIP is similar to that of heat-treated conditions. According to the ASTM standard for powder bed fusion fabricated Ti-6Al-4V4, the recommended HIP scheme corresponds to 100 MPa at 895 to 955 °C for 3 to 4 h. Several studies have performed HIP at 900−950 °C/100-150 MPa/2-4 h31,112,113,116, the resultant microstructure is mainly coarse α+β lamellar microstructure containing a few equiaxed α grains. For super-transus HIP, the prior-β grain will grow and the lath thickness in the lamellar microstructure will be controlled by the cooling rate in the HIP cycle.

-

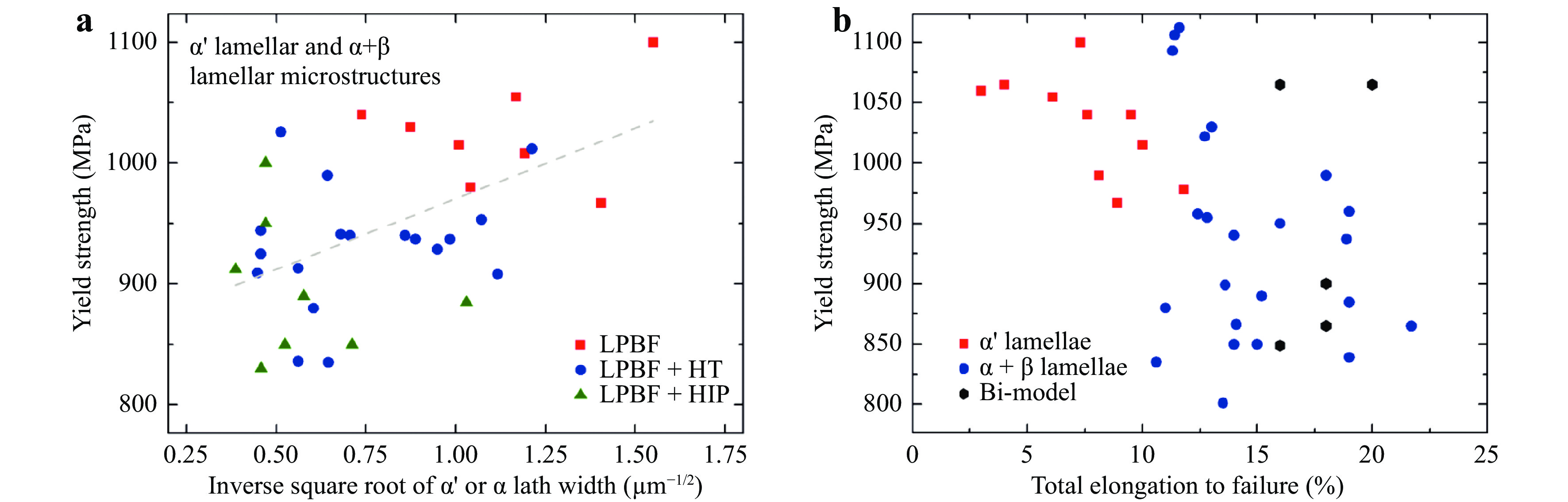

The most influential microstructural parameter that affects mechanical properties of LPBF fabricated lamellar structures is the α/α’ width35,64,76,96,117. Under extremely fast cooled condition, the effective slip length for dislocation is limited to the individual martensite width rather than the α colony size in thermomechanically processed Ti-6Al-4V1. The relationship between the strength and α/α’ width can be described by Hall-Petch relation as shown in Fig. 13a, in which a linear relationship can be established between the yield strength and the inverse square root of α/α’ width. Such a relationship is still valid after post-process annealing and HIP treatments in α+β phase field according to Fig. 13a. In general, the ductility exhibits an inverse relationship with the yield strength as shown in Fig. 13b. The as-fabricated LPBF Ti-6Al-4V has a fine α’ martensitic microstructure118, which results in a high strength but low ductility as shown in Fig. 13b and Table 1. Post-process heat treatments and HIP can promote the martensite decomposition to α+β lamellae, which reduce the strength and increase the ductility. A recent study found that heat treated LPBF Ti-6Al-4V with an equilibrium microstructure possesses a superior ductility (elongation at fracture (El.) > 18%) similar to that of wrought Ti-6Al-4V76. Details on the martensite decomposition in post-process treatments have been summarized in the previous section of annealing. With respect to the lamellar microstructure, the overall trend is a higher heat/HIP treatment temperature (below the β transus) and/or a longer heat/HIP treatment time lead to a lower strength but a higher ductility as shown in Table 1.

Fig. 13 The effect of microstructure on tensile properties.

a A Hall-Petch relation between yield strength and the width of α’ or α laths in Ti-6Al-4V with a lamellar microstructure fabricated by LPBF31,54,63,64,94,112,119, LPBF and post-process heat treatment16,31,120,121,60,63,76,83,84,94,103,119, and LPBF and post-process HIP31,60,103,112,113,119,122. b Yield strength vs. total elongation to failure for Ti-6Al-4V fabricated by LPBF with α’ lamellar microstructures[16,31,54,60,63,76,84,119,120, α+β lamellar microstructures31,63,121,123,124,64,83,84,94,96,103,119,120, and bi-modal microstructures102,104,110.Condition & Ref. Platform heating (°C) Post-LPBF treatment Microstructure YS (MPa) UTS (MPa) El. (%) As-LPBF

112100 − α’ lamellar 1008 (V) 1080 (V) 1.6 (V) 116 100 − α’ lamellar − 1315 ± 16 (V) 4.0 ± 1.2 (V) 31 70 − α’ lamellar 1065 (H)

1060 (V)1250 (H)

1090 (V)4 (H)

3 (V)120 − − α’ lamellar 1055 (H) 1098 (H) 6.1 (H) 16 500 − α’ lamellar 1137 ± 20 (H)

926 ± 47 (V)1206 ± 8 (H)

1116 ± 25 (V)7.6 ± 2 (H)

1.7 ± 0.3 (V)54 − − α’ lamellar 1140 ± 35 (H) 1130 ± 31 (H) 7.6 ± 1.1 (H) 76 100 − α’ lamellar 1040 ± 11 (H) 1201 ± 10 (H) 9.5 ± 0.2 (H) 63 − − α’ lamellar 978 ± 5 (H)

967 ± 10 (V)1143 ± 6 (H)

1117 ± 3 (V)11.8 ± 0.5 (H)

8.9 ±0.4 (V)64 ,* 200 − α+β lamellar 1100 (V) - 11.4 (V) 96, * 200 − α+β lamellar 1022 ± 10 (V) 1109 ± 10 (V) 12.7 ± 2.1 (V) Heat treated

60− 670 °C/5 h Partially decomposed α’ lamellar 1015 (V) 1090 (V) 10 (V) 103 − 700 °C/2 h/FC Partially decomposed α’ lamellar 1051 (V) 1115 (V) 11.3 (V) 63 − 730 °C/2 h/FC Partially decomposed α’ lamellar 958 ± 6 (H)

937 ± 9 (V)1057 ± 8 (H)

1052 ± 11 (V)12.4 ± 0.7 (H)

9.6 ± 0.9 (V)76 100 700 °C/2 h/FC Partially decomposed α’ lamellar 1012 ± 9 (H) 1109 ± 10 (H) 9.5 ± 0.2 (H) 116 100 800 °C/2 h/FC Partially decomposed α’ lamellar - 1228 ± 32 (V) 8.0 ± 1.5 (V) 76 100 800 °C/6 h/FC α+β lamellar 937 ± 4 (H) 1041 ± 5 (H) 19 ± 1 (H) 124, ** − 920 °C/2 h/FC α+β lamellar 850 (V) 933 (V) 15 (V) 112 100 1050 °C/2 h/FC α+β lamellar 798 (V) 956 (V) 11.6 (V) 116 100 1050 °C/2 h/FC α+β lamellar − 986 ± 45 (V) 13.8 ± 0.8 (V) HIP treated

103− 900 °C/100 MPa/2 h α+β lamellar 885 (V) 973 (V) 19 (V) 60 − 920 °C/100 MPa/2 h α+β lamellar 850 (V) 960 (V) 14 (V) 116 100 920 °C/100 MPa/2 h α+β lamellar − 1089 ± 26 (V) 13.8 ± 1.3 (V) 124, ** − 920 °C/120 MPa/2 h α+β lamellar 839 (V) 941 (V) 19 (V) 123 ,** − 930 °C/100 MPa/4 h α+β lamellar 866 ± 50 (H)

865 ± 3 (V)938 ± 43 (H)

936 ± 4 (V)14 ± 2 (H)

22 ± 2 (V)116 100 1050 °C/100 MPa/2 h α+β lamellar − 1007 ± 15 (V) 13.5 ± 0.7 (V) Heat treated

104,125− 910-930 °C/8 h/WQ + 750 °C/4 h/FC α+β bi-lamellar/bi-modal ~900 (V) ~950 (V) ~18 (V) 110 150 Thermal cycling between 975 °C and 875 °C/24 h/AC α+β bi-modal 865 ± 19 (H)

849 ± 12 (V)1017 ± 16 (H)

1004 ± 23 (V)18 ± 1 (H)

16 ± 1 (V)102 − 900 °C/100 h/AC α+β bi-modal ~1080 (V) ~1120 (V) ~20 (V) * Specimens were fabricated on support structures. ** Specimen surface was polished. Table 1. Microstructure and mechanical properties of LPBF fabricated Ti-6Al-4V in as-printed, heat treated, and HIP treated conditions. Air Cool (AC) and Furnace Cool (FC) are cooling methods after heat treatment. YS-Yield Strength, UTS- Ultimate Tensile Strength, and El.- Elongation at fracture are measured tensile properties.

In addition to the lamellar microstructure, another bi-lamellar/bi-modal microstructure can be achieved by post-process α+β STA and/or cyclic heat treatments which are described in the sections of solution treating and aging. As shown in Fig. 13b and Table 1, the bi-modal microstructure generally has an improved ductility without sacrificing strength when compared to the tensile properties of lamellar microstructure. The simultaneously enhanced strength and ductility are related to the fine αs region and the coarse equiaxed αp, respectively107.

A further information that can be extracted from Fig. 13 is the scattered tensile property in LPBF fabricated Ti-6Al-4V, which can be attributed to the various specimen orientations, compositions, porosity levels, and microstructures resulting from different powder characteristics (size and composition), LPBF systems, exposure parameters/strategies, and post-LPBF treatments.

Despite the efforts on transforming a non-equilibrium α’ martensitic microstructure into the an equilibrium α+β lamellar microstructure, a few studies have reported similar ductility in a fully martensitic microstructure when compared to that in an α+β microstructure80,126–128. In hot deformed Ti-6Al-4V, a rapid heating (> 50 °C/s) to the β phase field followed by water quenching lead to the formation of fine prior-β grains (~8 µm) containing only α’ martensite, which simultaneously improves strength and ductility126. The increase in strength is attributed to the refinement in both martensite width and prior-β grain size, and the enhanced ductility is related to the reduced strain localization due to the shortened martensite, which is limited by the prior β grain size126. Two similar observations have been reported in LPBF fabricated Ti-6Al-4V, in which a fully martensitic lamellar microstructure with a fine prior-β grain width between 50-100 µm results in high strength and ductility127,128. For such an approach to achieve good tensile properties, the key is to have a small prior-β grain size126. It is known that the prior-β grain width is related to the hatch distance in laser continuous scan strategy and the point distance in pulsed laser strategy. A small hatch distance can provide a narrow prior-β width, but it sacrifices the productivity. In addition, cautiously controlled laser processing parameters are required to avoid the β formation during the in-process thermal cycling, because the low volume of thin β film causes stress concentration, which decreases ductility127,128.

The mechanical properties of LPBF fabricated materials have been reported as anisotropic due to the columnar prior-β grains inclined close to the build direction113,129,130 and the manufacturing defects16,31. In the former case, horizontally built samples generally have a higher strength but a lower ductility than those of vertically built samples, because the width of columnar β grains is aligned in the tensile direction of horizontal samples113,129,130. The situation is changed when lack-of-fusion defects present between deposited layers and scan vectors. Vilaro et al. have reported higher elongation in horizontally built samples than that in vertically built samples in as-fabricated and post-process heat treated LPBF Ti-6Al-4V16. The reason is that tension in the vertical direction tends to open the lack-of-fusion defects and results in a low ductility. Recently, a plasticity model has been developed to predict the stress state dependent anisotropic plasticity behavior of LPBF fabricated Ti-6Al-4V131.

A recent study has revealed that β solution treatment can effectively mitigate the anisotropy in mechanical property due to the fact that β grains lost the columnar morphology after such a treatment132. However, the strength and ductility significantly decrease after β solution treatment, because excessive β grain growth occurs at temperature above the β transus84,132.

-

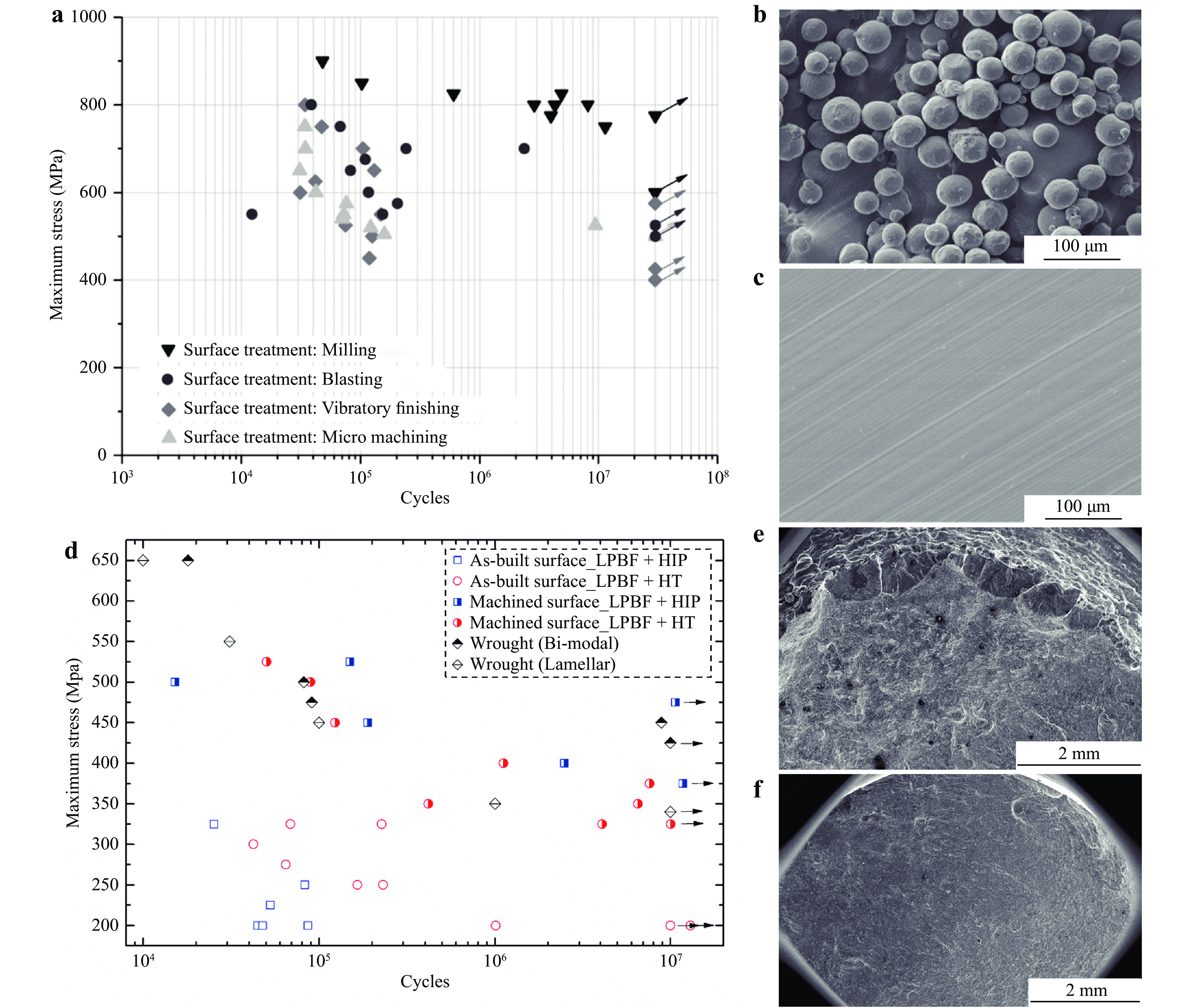

For LPBF fabricated Ti-6Al-4V, the fatigue performance is influenced by the surface finish, manufacturing defects, residual stress and microstructure133,134. The surface quality has been found to be the most crucial factor. Fig. 14b shows a rough as-built surface covered by partially melted powders. Without surface treatments, the fatigue performance of as-fabricated LPBF specimen is worse than that of the traditional cast products133. After surface treatment, the fatigue strength is significantly increased in LPBF Ti-6Al-4V with57,58,60,103 and without post-process HIP treatments58. Fig. 14a shows that various surface treatments can improve the fatigue performance, and a reduced surface roughness of Ra = 0.3 µm (Fig. 14c), achieved by milling, improves the tension-tension (R = 0.1) high cycle fatigue (HCF) strength to 775 MPa57, which is superior than that of wrought Ti-6Al-4V at 450–650 MPa135. Similarly, with respect to tension-compression fatigue (R = −1), Fig. 14d shows a similar observation that an improved surface quality increases the HCF strength, and a reduced surface roughness (Ra < 1 µm) provides a HCF strength comparable to that of wrought Ti-6Al-4V. This is consistent with the fractographs shown in Fig. 14e and f, which indicate that surface related defects are responsible for the inferior fatigue strength in the as-built sample, and fatigue crack initiation site is at the sample interior when the surface defects are removed by machining. The comparable or even higher HCF strength in improved surface conditions is because the LPBF fabricated Ti-6Al-4V has a much finer microstructure than wrought and cast Ti-6Al-4V, which means a short effective dislocation slip length and a high resistance to fatigue crack initiation.

Fig. 14 Effect of surface finish on HCF strength.

a Fatigue performance of post-process HIP treated LPBF Ti-6Al-4V after different surface treatments with an axial fatigue stress of R =0.157. b SEM micrograph of as-built surface (Ra = 17.9 µm)57. c SEM image of milled surface (Ra = 0.3 µm)57. d Fatigue performance of post-process heat treated or HIP treated LPBF Ti-6Al-4V with an axial fatigue stress of R =-11,58. e Fatigue fractograph of a sample with as-built surface (Ra > 7 µm)58. f Fatigue fractograph of a sample with machined surface (Ra < 1 µm)58.If the defects are on the surface and/or at the sub-surface which are connected to the surface, then HIP cannot close such the surface related defects and does not improve the fatigue strength of samples with an as-built surface quality as shown in Fig. 14d. In contrast, internal defects can be addressed by post-process HIP, which has been summarised in the section of hot isostatic pressing. Fig. 14d shows that HIP improves the fatigue performance of machined samples (Ra < 1 µm), which is through eliminating the internal defects. In addition, HIP can effectively narrow down the fatigue data scatter60. As described in the section of residual stress, tensile residual stress, which accelerates the fatigue crack propagation and is detrimental to the fatigue properties3, presents at the top and side surfaces of the part50. Therefore, surface peening treatments have been used to tackle the tensile residual stress, which result in a compressive stress below the surface and improves the fatigue strength60,136.

For the influence of microstructures, previous investigations are mainly focused on the lamellar microstructure. In general, a finer microstructure has a higher fatigue strength. A sub-transus HIP treatment at 920 °C shows a better fatigue performance than the super-transus HIP treatment at 1050 °C116. Similar observations has been reported in the heat treated conditions116. Whereas, the situation is different for fatigue crack growth (FCG). In the hypo-transitional region, FCG is generally influenced by the microstructure. A coarse microstructure has a higher fatigue crack threshold stress intensity factor (ΔKth) and a slower FCG rate137. At the threshold range, a coarser lamellar microstructure displays a stronger ability to deflect cracks along the lath boundaries137,138. Even at a higher ΔK, crack deflection can be controlled by the colony/packet size138. On the contrary, the cyclic plastic zone is sufficiently large in the hyper-transitional region, which exceeds the colony size, thus FCG is insensitive to the microstructure138.

-

As described in tensile and fatigue properties, a fine microstructure generally provides high yield and HCF strengths. In contrast, a fine microstructure leads to a low fracture toughness1. For LPBF Ti-6Al-4V, the fracture toughness has been reported at values below 30 MPa∙m−1/2 in the as-fabricated condition with α’ martensitic microstructure139. This is lower than that of the wrought Ti-6Al-4V with a lamellar microstructure at 45-75 MPa∙m−1/2 1,3. This is due to the extremely fine (sub-micro) and brittle α’ in the as-fabricated condition. It has been found that post-process stress-relieving and annealing can improve the fracture toughness to approximately 50 MPa∙m−1/2 139,140, which is comparable to that of wrought alloys. In addition, anisotropic fracture toughness has been observed in both as-fabricated and post-process stress-relieved/annealed conditions, which is related to porosity levels and columnar β grains aligned along the build direction. A recent study has showed that a two-stage heat treatment of α+β STA effectively improves the fracture toughness to approximately 100 MPa∙m−1/2 138. A short solution treatment at 920 °C followed by aging results in a coarse α+β Widmanstätten microstructure, and this microstructure can provide two benefits in terms of improving the fracture toughness. One is the α+β microstructure is more ductile than the α’ martensitic microstructure, and the other is a coarser lamellar microstructure means a rougher crack front profile and an increased crack tortuosity1,138.

In the temperature range between 450 °C and 650 °C, the as-fabricated Ti-6Al-4V has a comparable creep performance with that of the wrought Ti-6Al-4V141. After post-process heat treatments, a Widmanstätten microstructure showed a relatively lower creep strain and a lower steady-state creep rate than that in the as-fabricated condition. This indicates that the heat treated condition has a higher creep resistance142. This is due to the fact that the as-fabricated martensitic microstructure can be decomposed at creep testing temperatures, and such a microstructure evolution reduces the creep resistance142. The α/β interfaces in Widmanstätten microstructure act as obstacles to the dislocation glide during the creep deformation, which also improves the creep resistance143,144.

-

In titanium alloys, the corrosion resistance is attributed to the protective surface oxide film1. Therefore, the surface quality affects the corrosion performance of LPBF fabricated Ti-6Al-4V, and surface treatments can effectively improve the corrosion resistance by surface machining145 and electropolishing146. For the influence of microstructure, metastable α’ martensite is regarded as less corrosion resistant than the α phase, and the V-containing β phase is more corrosion resistant than α’ martensite147. Therefore, as-fabricated LPBF Ti-6Al-4V has an inferior corrosion resistance (in 3.5 wt.% NaCl aqueous solution at room temperature) when compared with conventionally processed Ti-6Al-4V with an α+β lamellar microstructure due to the non-equilibrium α’ martensitic microstructure147,148. The passive film thickness has been found to be thinner in laser fabricated Ti-6Al-4V than that in wrought counterpart, which also indicates a faster corrosion rate149. In terms of anisotropy, there is a negligible difference in corrosion properties between vertical and horizontal planes in 3.5 wt.% NaCl aqueous solution, while anisotropic corrosion behavior has been observed in a harsher environment of 1 M HCl aqueous solution, and the authors have related the anisotropy to different β volume fractions on different orientations150.

After post-process heat treatments, previous studies showed two distinctly different corrosion phenomena. A recent study has reported that both sub-transus and super-transus heat treatments deteriorated the corrosion resistance in 3.5 wt.% NaCl aqueous solution at room temperature due to the increased grain size151. While, other studies have suggested that post-process heat treatments improve the corrosion resistance in Ringer’s solution at 37 °C152 and in 3.5 wt.% NaCl aqueous solution at room temperature147. This is attributed to the limited element segregation in the μm-sized α+β lamellar microstructure after the heat treatment, which mitigates the galvanic corrosion between α and β phases147. Nevertheless, further investigations on the corrosion performance of SLM-produced Ti-6Al-4V are required to understand the influence of post-process heat treatments.

-

In this paper, the LPBF process, post-process treatments, microstructures, and properties of LPBF fabricated Ti-6Al-4V have been briefly reviewed. At the beginning, the influences of processing parameters on the defect formation, residual stress, and surface roughness are presented. This is followed by the as-fabricated microstructure and its evolution during the in-process and post-process treatments. Lastly, the effects of microstructure, defects, and surface roughness on tensile, fatigue, fracture toughness, and creep properties are discussed. A summary of specific findings is provided below:

● The formation of defects and surface quality can be controlled by tuning the processing parameters and scan strategies.

● The residual stress and pores in the as-fabricated Ti-6Al-4V can be addressed via post-process HIP treatments.

● The as-fabricated Ti-6Al-4V generally has a hierarchical microstructure containing textured prior-β grains that are aligned close to the build direction and intragranular hexagonal α’ martensitic microstructure. In addition, a few studies have observed a small amount of β, α2, and orthorhombic α’’ martensite in the as-fabricated condition.

● The microstructure evolution, including martensite decomposition and formation of lamellar and/or bi-modal α+β microstructures, can be realized via in-process thermal cycling and post-process treatments.

● For the lamellar microstructure, the yield strength follows a Hall-Petch relationship with the lamellar width in the as-fabricated and post-process treated samples. The typical trade-off between strength and ductility is observed within the sample with a lamellar microstructure. In contrast, the bi-modal microstructure can provide a simultaneous enhancement in strength and ductility.

● After surface treatments, the fine microstructure in as-LPBF and post-process treated conditions leads to a high HCF strength. In contrast, a coarse α+β Widmanstätten microstructure is preferred for obtaining good fracture toughness and creep properties.

● In terms of corrosion resistance, the as-fabricated Ti-6Al-4V has an inferior corrosion performance than that of wrought counterpart, which is related to the metastable α’ martensitic microstructure. A more detailed understanding of the influence of post-process heat treatments on the corrosion behavior is required.

● Most post-process treatments, including heat treatments, HIP, and surface treatments, lead to comparable or even superior tensile, fatigue, fracture toughness, and creep properties than those of cast and/or wrought Ti-6Al-4V.

-

In principle, LPBF fabricated Ti-6Al-4V has great advantages in preparing complex near-net shape parts and reducing lead times. However, there is still a gap between the current research and the aforementioned advantages. For example, surface roughness and internal defects require post-process surface treatments and HIP to address. Additionally, disadvantages of anisotropic microstructure and properties must be considered, and the mitigation of anisotropy requires further investigation.

In terms of microstructure and properties, LPBF fabricated Ti-6Al-4V possesses a fine microstructure, which offers great advantages, including superior tensile and HCF strengths. However, a fine microstructure is not favorable for fracture toughness and creep resistance. A careful microstructure design through post-process treatments is required for specific applications.

In contrast to the inverse relationship between tensile strength and ductility in the lamellar microstructure, the bi-modal microstructure shows a great potential in terms of achieving satisfied strength and ductility. In addition, the bi-modal microstructure shows a higher HCF strength, a slower fatigue crack propagation rate of microcracks, and a higher LCF strength in wrought and cast alloys. As a two-step α+β STA treatment is generally used to obtain a bi-modal microstructure, the alloy element partitioning effect inevitably occurs. Future studies are required to understand the effect of strength difference between the initially formed αp and the subsequently formed αs on properties at a fine scale in LPBF fabricated Ti-6Al-4V.

-

This work is funded by Australian Research Council IH130100008 “Industrial Transformation Research Hub for Transforming Australia's Manufacturing Industry through High Value Additive Manufacturing”. The authors gratefully acknowledge useful discussions with Kai Zhang and Jianwen Liu from the University of Shanghai for Science and Technology.

Review of laser powder bed fusion (LPBF) fabricated Ti-6Al-4V: process, post-process treatment, microstructure, and property

- Light: Advanced Manufacturing 2, Article number: (2021)

- Received: 22 January 2021

- Revised: 15 July 2021

- Accepted: 16 July 2021 Published online: 13 August 2021

doi: https://doi.org/10.37188/lam.2021.020

Abstract: Laser powder bed fusion (LPBF) is a timely important additive manufacturing technique that offers many opportunities for fabricating three-dimensional complex shaped components at a high resolution with short lead times. This technique has been extensively employed in manufacturing Ti-6Al-4V parts for aerospace and biomedical applications. However, many challenges, including poor surface quality, porosity, anisotropy in microstructure and property, and difficulty in tailoring microstructure, still exist. In this paper, we review the recent progress in post-process treatment and its influence on the microstructure evolution and material performance, including tensile, fatigue, fracture toughness, creep, and corrosion properties. The contradictions in simultaneously achieving high strength/ductility and strength/fracture toughness/creep resistance have been identified. Furthermore, research gaps in understanding the effects of the emerging bi-modal microstructure on fatigue properties and fracture toughness require further investigation.

Research Summary

Controllable microstructure and property in additive manufactured titanium alloy

Over the last two decades, laser powder bed fusion (LPBF) has become one of the most widely used additive manufacturing technique. Among different alloys, LPBF fabricated titanium alloys have attracted much attention due to their good mechanical properties, outstanding corrosion resistance, and superior biocompatibility. The microstructure and properties of LPBF fabricated titanium alloys are significantly affected by the 3D printing process and post-process treatments. Researchers at the University of Manchester and Monash University now give an overview of the LPBF fabricated Ti-6Al-4V in terms of the processing-microstructure-property relationship. Through applying appropriate process parameters and post-process treatments, LPBF fabricated Ti-6Al-4V has comparable or even superior tensile, fatigue, fracture toughness, and creep properties than those of cast and/or wrought counterparts. However, there are still contradictions in simultaneously achieving high strength/ductility and strength/fracture toughness/creep resistance.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article′s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article′s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

DownLoad:

DownLoad: