-

The complexity of industrial products and procedures is increasing annually, leading to challenges in manufacturing, assembly, maintenance, and repair. Human errors, the lack of reliable data on operations performed, mistakes made, and constant external control contribute to equipment failures and accidents, often due to problems in accessing and interpreting technical documentation1. Implementing augmented reality (AR) glasses can help reduce errors caused by human factors and provide operators with hands-free access to digital assembly instructions and remote expert assistance2. This allows the user to gain a better understanding of the object in question while not limiting their mobility. AR technology improves operational efficiency, reduces equipment downtime, and reduces staff qualification requirements. It enables the establishment of a unified service center for real-time guidance and support.

AR devices, which are optical see-through (OST) head-mounted displays (HMDs), are one of the most effective tools for solving these problems3. AR devices add an “information layer” to a person’s normal perception. Linked to products and parts, this layer contains fundamental data about them, thus offering virtual cues. HMDs address the issue of insufficient user awareness by providing the necessary data in real time. Additionally, the use of AR devices allows for remote technical support of personnel, facilitating real-time communication between technicians, designers, and technologists.

To analyse the global experience of headset implementation in the manufacturing process, an extensive literature search was conducted, including both research and review papers. A number of reviews have been published, presented in Table 1, describing both the headsets themselves and aspects of the hardware and software development, as well as possible cases of their application. These reviews also address the effects of implementation in manufacturing such as an elimination of paper documents, convenient visual instructions and increased efficiency1−3, 22, 24, as well as limitations at the enterprise level which include issues of fatigue and visual discomfort20, ergonomics2, 22, limited field of view (FOV)2, tracking and rendering (i.e., difficulties in sensors and sensing techniques for estimating human motion and environmental perception3, processing speed issues3 and privacy and cybersecurity1, 20, 22; description of headsets and available software5, 6, 8, 9, 16, 18, 20; existing technologies of human-machine interaction technologies10, 11, 24; tracking and referencing to surrounding objects3, 11, 13, 16, 20, 22, 24, and other relevant topics4, 12, 15, 17, 19, 21.

Ref. Year Cases Effects Headsets & Soft Usability Ergonomic Main focus on 4 2011

key concepts; systems; applications; trends 5 2011

applications; difficulties and challenges 6 2012

applications in manufacturing; hardware and software 7 2016

assembly systems; limitations; trends 8 2017

training-on-the-job application; usability 9 2018

industrial and shipbuilding applications 10 2018

maintenance applications 11 2018

state of the art of AR in maintenance 12 2019

scientific analyses about industrial applications 13 2020

development from an engineering perspective 14 2020

applicability and usefulness on real industrial processes 15 2020

industrial AR application cases 16 2020

citation network analyses, applications in manufacturing 17 2021

applications in assembly; advantages; current limitations 18 2021

Hololens’ applications in several industries 19 2021

application analyses; devices; tracking methods 20 2022

design; maintenance; assembly; hardware and software 21 2022

applications for industry 4.0 22 2022

research projects; manual assembly 23 2022

use in manufacturing; key limitations; future perspectives 2 2023

case studies; interaction ways 3 2023

Hololens features; scene perception 1 2023

assembly; critical difficulties; tracking, rendering 24 2023

applications; interaction; methods; challenges p.w. 2024

image quality; usability; applications in manufacturing Table 1. Sample study list on HMD AR in manufacturing.

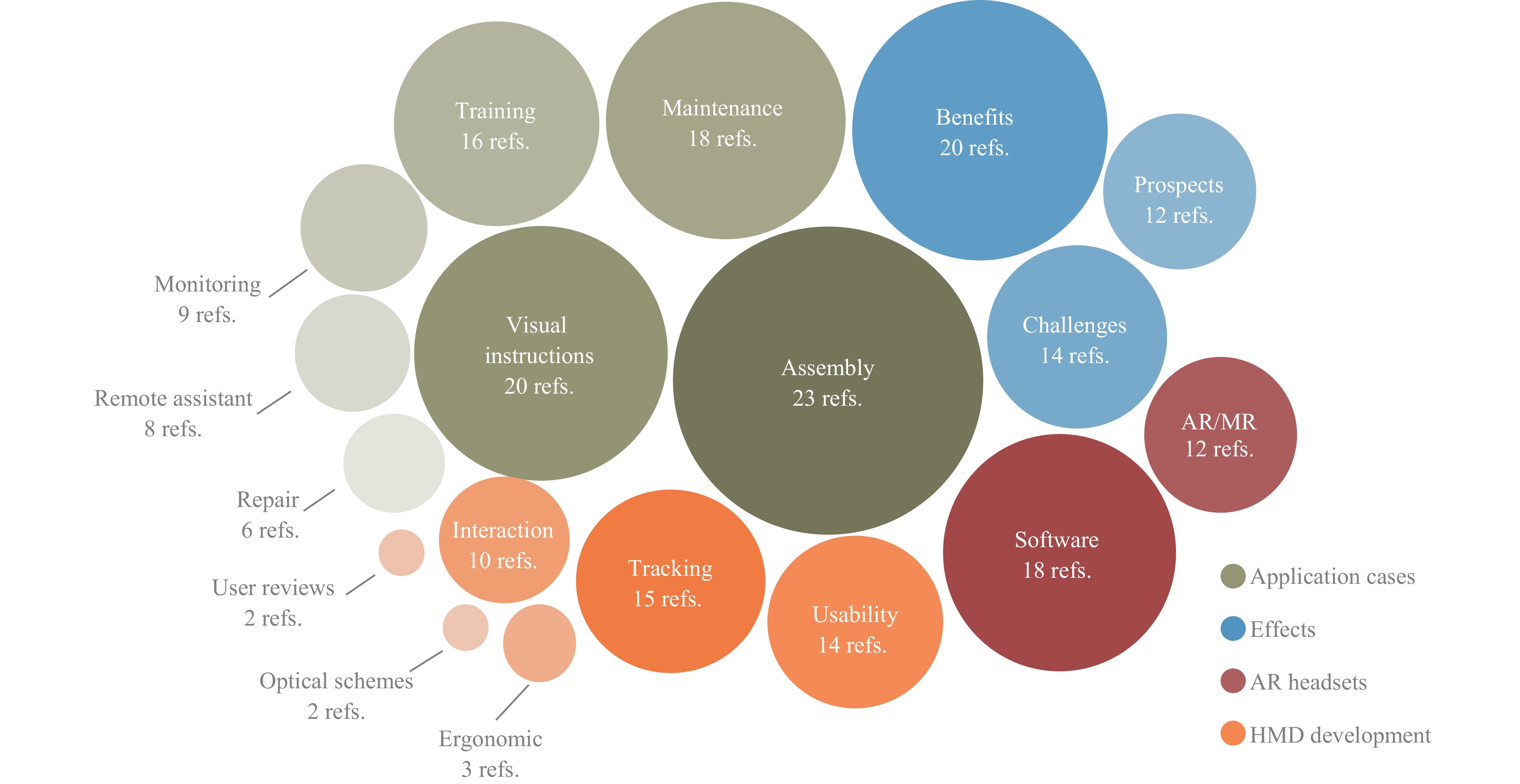

The aim of the current study was to analyse the existing literature on the use of AR headsets in industrial manufacturing to identify the key aspects related to this topic. The present work (p.w.) provides an in-depth understanding of the most popular application cases, the headset management, tracking, and usability features associated with them, and the application effects, including advantages, prospects, and limitations associated with integrating headsets into industrial applications. The data on keywords and main topics has been collected and presented in the form of a diagram Fig. 1, which provides a clear overview of the information. For consistency, the colours used in Table 1 and Fig. 1 are the same.

A review of the literature reveals that a significant proportion of research attention has been devoted to the application of AR headsets in the industry. The most common cases are assembly, repair, installation, and maintenance (including visual instructions), and remote expert. Application cases are directly related to software development tasks, and therefore the peculiarities of this field are frequently discussed. Among the hardware implementation issues, the following are predominantly considered: visualisation, registration, rendering, tracking, and occlusion. Concurrently, the assessment of the optical schemes of headsets, which will directly impact the image quality and the user’s visual perception, is not conducted.

The statistics presented in Fig. 1 indicate that ergonomic concerns are infrequently addressed compared to tracking and interaction issues. In this regard, ergonomics (focused on physical factors) and usability (focused on interaction) have been highlighted in Table 1 to further demonstrate the elaboration of these issues in the for further demonstration of elaboration of these issues in the analysed works. While ergonomics primarily focuses on factors such as weight, size, ease of device use, and musculoskeletal discomfort, there is a noticeable lack of discussion on practical evaluation of these aspects in industrial settings and the associated limitations. Herewith, evaluating the ergonomics of AR headsets is crucial to developing the next generation devices aimed at the comfort, efficiency, and safety of workers using this technology. Standard parameters for industrial AR headsets have not been developed, so one of the objectives of the present work was to define recommendations for their determination depending on the conditions and application case.

In essence, this review’s central objective is to assess the practical applications of AR HMDs in manufacturing, coupled with the ergonomic aspects of their use. To achieve this, a series of queries were formulated, including:

• comparative analysis of various headset types utilised in the manufacturing,

• assessment of the quality of the "virtual display" depending on the optical configuration of the headset,

• analysis of the applicability of headset designs, considering usability and feedback from the workforce,

• identification of fundamental headset requirements for distinct industrial application contexts,

• determination of metrics for an objective evaluating the suitability of headsets and their comparative analysis in a specific industrial application case.

As illustrated in Fig. 1, the aforementioned issues have not yet been fully investigated. Our opinion is that a more comprehensive examination of these matters will facilitate an accurate assessment of the current state of AR technologies in the industrial sector, as well as the existing barriers and potentials for future development. For these reasons, this review will be of particular interest to specialists in optics, especially those engaged in the development of AR devices. It is anticipated that this article will function as a form of feedback, supported by the findings of usability studies conducted on the optical visual devices in question. The following is a summary of the work. Initially, the application cases of AR devices in the industrial sector are reviewed. Subsequently, the most common AR headsets are analysed. Finally, the results of their experimental benchmarks, conclusions, and outlook are presented.

-

Many manufacturing plants are faced with the challenge of simultaneously increasing labor productivity, optimizing costs, and reducing errors when working with complex equipment, during assembly, repair, etc. is being addressed. The application of AR technology allows the workforce to always have access to the necessary information in the most visual format, including design and technological documentation, connection and wiring diagrams, 3D models, and other visual information. This approach enables the digitalisation of production and assembly processes to the maximum extent at the enterprise level. For the average employee-user, it provides the ability to focus on work without distractions on paper-based technical documentation25, eliminates the need to leave the workstation to search for information, and enables hands-free operation through voice and gesture controls, unlike using smartphones and tablets26, 27.

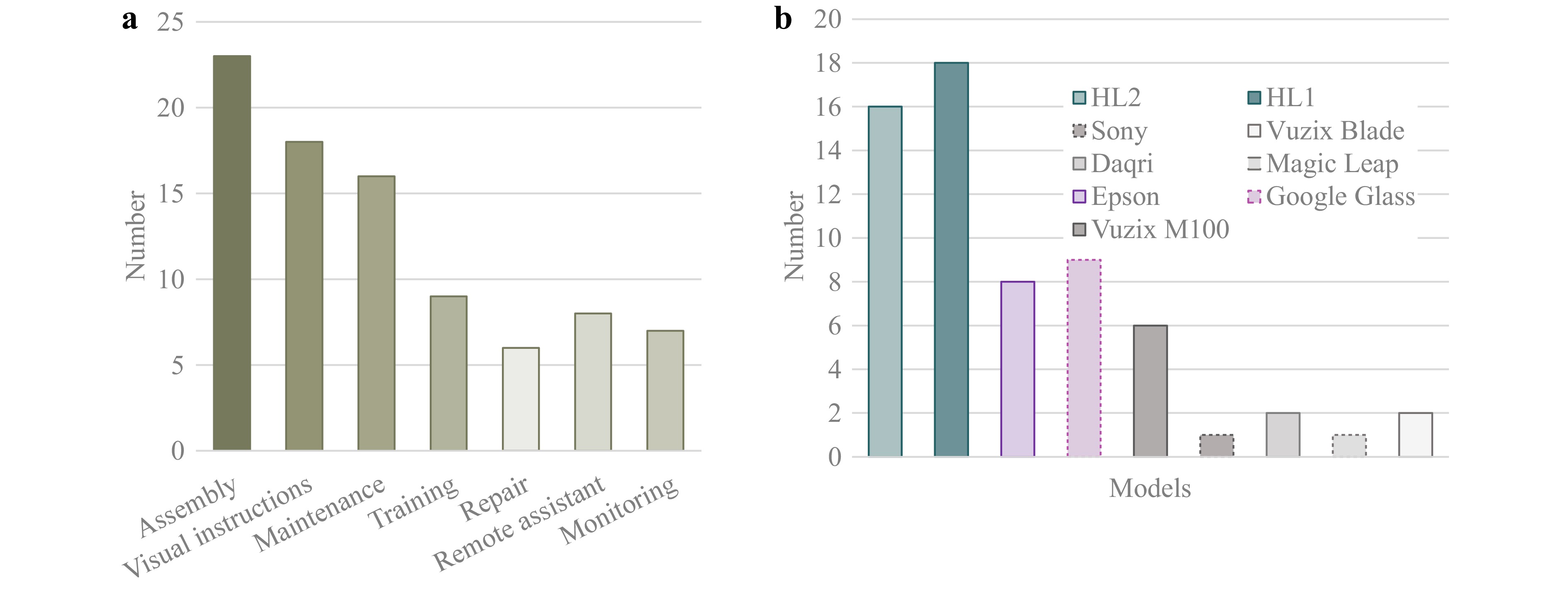

Considering the authors’ prior reviews and experience of utilising headsets in the industrial sector, the main application cases can be identified as follows. These include assembly and disassembly of products28−33, maintenance34−36, repair of equipment15, 37 product quality control8, 15, 38, control inspections12, 14, 21 and equipment monitoring2, 8, 17, 30, diagnostic12, visualisation of installations in hidden areas9, safety management8, communication with a remote expert39, 40−42 and training43−45. Training is a stand-alone area because it is relevant not only to the manufacturing sector but also to other areas17, 18, 43. The scenario for outputting visual instructions is frequently referenced in the literature46−50, yet it is a component of a number of other cases, including those pertaining to assembly, installation, and repair. To provide a comprehensive overview of how these cases are distributed in the existing literature, they have been grouped into some general categories as illustrated in Fig. 2a.

Fig. 2 Literature review results. a Distribution of AR headsets in manufacturing, b Distribution of industrial AR applications.

In the initial classification of AR headsets, two groups were distinguished: one comprising headsets with diffractive/holographic couplers and the other with refractive/reflective couplers51. It is important to acknowledge that, from the perspective of the hardware platform, Microsoft (MS) headsets were the primary choice for the implementation of the cases described above. This is evidenced by a large number of publications that mention Hololens 1 (HL 1)52−59 and Hololens 2 (HL 2)18, 44, 45. This distribution is illustrated in Fig. 2b. It is our considered opinion that both the hardware capabilities and the optical design of the device have an impact on its overall usability. The next most frequently mentioned devices are Google Glass (GG)60−68, Epson Moverio68−70 and Vuzix M10068, Vuzix25, 66, 71−73. Less frequently mentioned are Daqri74, 75, Sony76 and Magic Leap18.

It should be noted that there has been practically no assessment of the ergonomics of such headsets, although there are articles devoted to small FOV and visibility of virtual objects77−79, eye fatigue48 and discomfort in the muscles of the neck and shoulders, which is associated with the weight of the headset80.

In the context of the assembly, maintenance, and repair of engineering products, AR headsets allow the operator to record and simultaneously control the technological process via a video image at each stage, due to the presence of cameras. On the other hand, it assists the operator during the assembly process by displaying visual instructions, hints, and animated videos against the background of the product.

As with assembly, maintenance and repair involve the provision of visual instructions, and text tips. Three-dimensional models are also provided to help the user understand the appearance and composition of the product. Additionally, the ability to access drawings, diagrams, and other documentation in a hands-free mode is provided at the right time.

In the context of the “Remote Assistance” case, AR facilitates the virtual support for the installation or repair of complex equipment in production to specialists from anywhere in the world, i.e. via a first-person video call. An illustrative example is the failure of complex equipment. Operators can put on a headset, contact an expert, and quickly begin repairs. In turn, the expert, seeing the equipment from the operator’s perspective, can use graphical interfaces to highlight details, indicate movements, or display relevant data in real time15.

In the context of equipment monitoring and control, a user is guided through a set of step-by-step instructions displayed in their FOV in a graphic and text format. This involves entering data, taking photos and video recordings of control events, and noting any deviations or incidents that may occur. These processes can be carried out without the use of tablets or smartphones, allowing the user to remain hands-free2.

One of the key benefits of AR headsets is their ability to facilitate hands-free learning through the practical implementation of visual cases in AR. These cases are displayed as three-dimensional virtual models, devices, and equipment, accompanied by text or voice instructions. This approach offers numerous advantages over traditional training methods, including the ability to interact with the real tools specified in the training scenario while simultaneously viewing the materials in front of them. In this manner, the individual can practise the actual use of the tools through which the relevant sensorimotor skills are trained6. AR training has become a popular area in the industrial segment, with a steady increase in the number of users each year.

A summary of the data obtained from the sources reveals that the utilisation of AR headsets in manufacturing offers a multitude of undoubted advantages and crucial effects. These include:

• utilising the principle of “the right data at the right time, right in front of your eyes”;

• emphasizing graphical representation of the required information simplifies human-device interaction as much as possible1;

• implementation of the “hands-free” principle, i.e. freeing the worker’s hands to perform current operations, as opposed to using smartphones and tablets3;

• reduction of personnel training time due to the application of the “learning by doing” principle6;

• reducing the probability of human error20, 62;

• increased productivity, accuracy of operations and labour safety14;

• reduction of logistics costs in certain areas20;

• elimination of paper-based information carriers, reports, and logs25.

At the same time, there are a number of barriers related to the complexity of implementing AR headsets1, 81 tracking accuracy, as well as the quality of the virtual display and its brightness66, 82. The occlusion problem remains unresolved30, 3.

To accommodate the diverse needs of users across the cases outlined, it may be necessary to implement the specific types of headsets, which will be further elaborated upon in the subsequent section.

-

At the present time, a multitude of distinct headsets have been developed with the objective of addressing issues pertaining to assembly, installation, and maintenance, among other concerns (including those pertaining to already implemented cases). An in-depth analyses was conducted on the six headsets with the years of production indicated on the timeline diagram in Fig. 3. Each headset in this set is implemented using its technology, which gives rise to a number of characteristics, technical parameters, a specific set of sensors, and so forth. These characteristics determine the effectiveness of the headset in certain tasks and scenarios. It is therefore necessary to conduct a comparative analysis of the various types of headsets currently available in order to assess their respective capabilities and user comfort, as well as to examine their practical application in the context of industrial production.

Fig. 3 Timeline for the analysed headsets based on: diffractive/holographic coupler elements (top) and refractive/reflective coupler elements (bottom).

At this time, a multitude of different headsets have been developed to address assembly, installation, and maintenance issues. This includes those headsets that have already been implemented in the manufacturing process and were presented in Fig. 2b, among others. A comprehensive examination of the following popular models has been conducted: MS HL 1 and 2, Vuzix M4000, Rokid X Craft, Epson PRO BT-2200, GG EE XE, XReal Air 2 and Rokid Max. Some have been demonstrated to be effective for industrial applications and training18, 65, 69, 83, 84, while others are relatively novel and yet to be fully evaluated. The release years are presented in the timeline diagram in Fig. 3. Each headset in this selection has been implemented using a unique technology, resulting in a distinct set of characteristics, technical parameters, a specific set of sensors, and so on. These characteristics determine the effectiveness of the headset in specific tasks and cases. Consequently, a comparative analysis of different types of headsets is imperative, as is an assessment of their capabilities and user comfort. Therefore, a comprehensive study of their practical applicability in industrial production contexts is essential.

Since each headset is, in fact, a wearable display that generates additional and virtual images, it is crucial to examine and compare these devices, with a particular focus on the user’s perceived image quality. According to B. Kress85, the optical AR-design task must be considered as a human-centric task. Human factors, in this case, include those that take into account the specifics of human vision, namely: perceived angular resolution, FOV, limitation of human-vision FOV, colour uniformity, chromatic aberrations, and visual acuity.

It should be noted that other human factors related to different aspects of the user’s visual perception can also be highlighted, specifically: vergence-accommodation conflict and methods for its elimination86, 87, the effects of interpupillary distance mismatch88, laser safety issues when using laser beam scanning display, as well as the risk of eye injury from shattered glass fragments in the case of headset damage89. However, these problems are common to most of the headsets under consideration, so they are not discussed separately in this paper.

A series of design strategies for city-friendly AR interfaces are proposed in Ref. 90. These strategies are unified by a context-aware interaction paradigm and are based on an analysis of a number of human perception problems, including the user’s cognitive load, content access, human vision features, and readability. For a more detailed introduction to the issues pertaining to human factors and usability criteria in headset design, please refer to the paper in Ref. 91.

Therefore, the principal quality parameters influencing human factors to be considered in the described context include:

• FOV, the angular area within which the virtual images can be displayed. The objective is to maximise the user’s FOV;

• eye-box, the volume of space in which the eye can observe the output image with the required quality parameters when displaced;

• brightness characterises the possibility of using the device in illuminated rooms or field conditions;

• resolution, the minimum size of characters that can be presented to the user;

• the combination of colour uniformity and chromatic aberrations was termed ‘colour rendering’.

These parameters will be investigated during the comparative analysis of AR headsets. The optical scheme of the headset will determine and often limit the parameters of image quality. The next section will describe the construction principles of optical systems, and their parameters for several headsets that were tested to determine the capabilities and features when used in manufacturing. To gain a more comprehensive insight into the optical systems of transparent displays and their classification, it is recommended to refer to the sources85, 92, 93. As previously mentioned in Fig. 3d, the OST displays under study can be divided into two principal categories based on:

(i) diffractive/holographic couplers elements,

(ii) refractive/reflective couplers elements.

-

MS HL is an HMD AR device that, using depth sensors and cameras, performs spatial mapping and recognition of environmental objects. HL advantage is the ability to gaze tracking3, 94, 95 and place virtual objects in certain positions relative to real objects82.

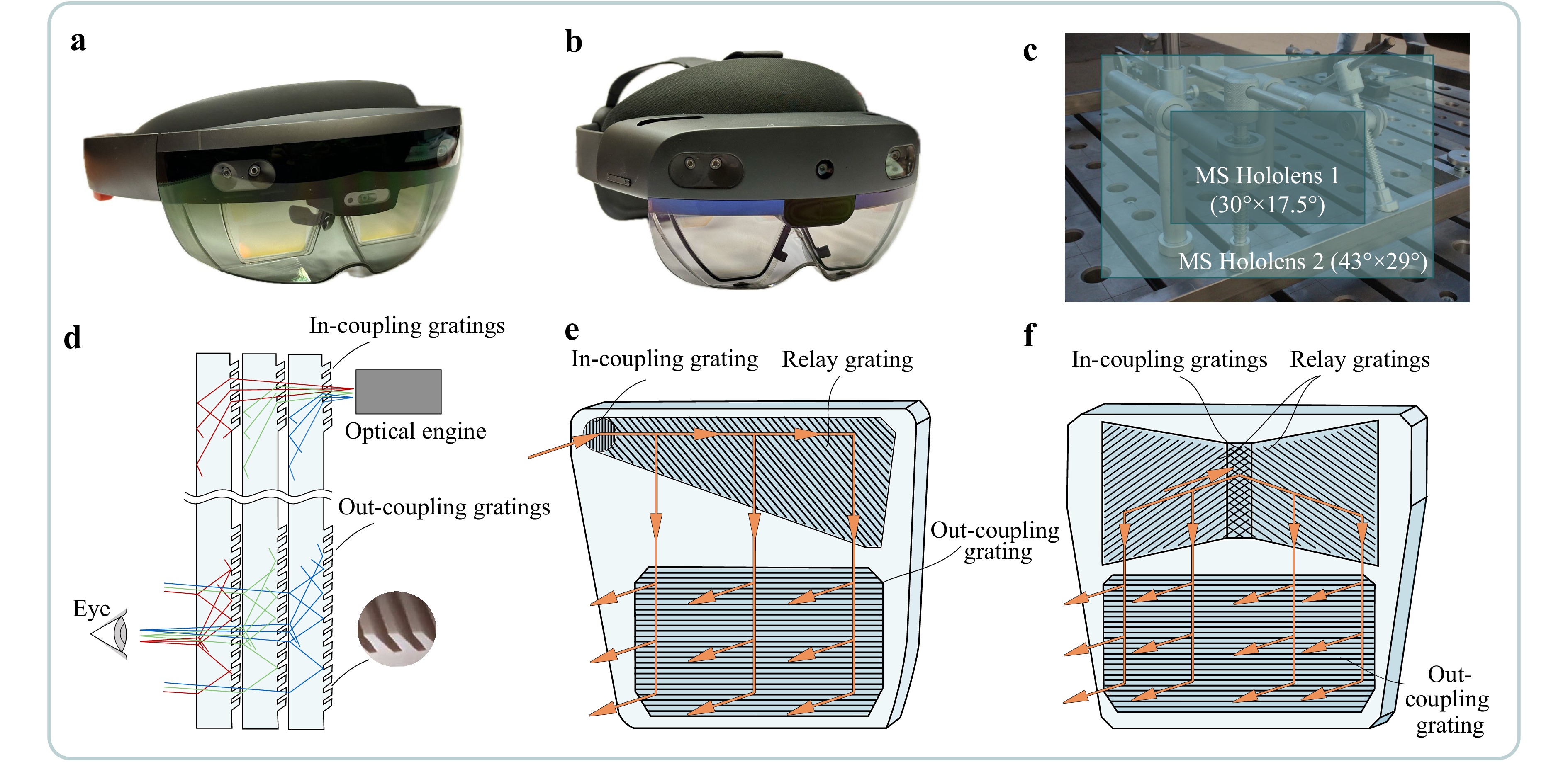

At the moment, there are two implementations of AR glasses from Microsoft: HL 1 and HL 2, shown in Fig. 4a, b, respectively96. They have a few fundamental differences. The most noticeable one is the design of the headset. The battery and processor in HL 2 have been moved to the back of the head, improving the weight balance of the second version. In addition, the ability to flip the display has been added. Hand tracking and gesture control in HL 2 are significantly improved over HL 1. The improvement of FOV in the second generation of the device compared to the first is shown in Fig. 4c.

Fig. 4 HMD AR by Microsoft: HL 1 headset a and HL 2 headset b, comparison of FOV for HL 1 and HL 2 c, scheme of the 3-channel colour transparent display based on planar diffractive waveguides d, 2D pupil replication layouts for different configuration of the diffractive waveguides: HL 1 e and HL 2 f.

MS HL uses diffractive waveguide technology to create images superimposed on the real world97, 98. A feature of thus design is that diffraction gratings are formed on its surface for the input and output of light beams, as shown in Fig. 4d. The rays from the optical engine propagate in a plane-parallel waveguide plate using total internal reflection (TIR), overcome a significant optical path inside the waveguide, and are transferred to the observer’s eye. Fig. 4d illustrates the principle of FOV conversion for a three-channel full-colour display. The transmission of red, green and blue (RGB) light is depicted in isolation for a three-layer waveguide as realised in the MS HL1 device. In reality, light beams with different wavelengths may partially overlap in an angular field according to the grating equation98. In the MS HL2 device, a dual-channel display is implemented. Instead of three layers of waveguides for the RGB light source, the MS HL2 uses two. One planar waveguide converts the entire FOV for red light and a portion for green light, while the second layer waveguide transmits the other portion of the FOV for green light and the entire blue spectrum. To change the direction of ray propagation, relay grating is used. This ensures the eye-box expansion in two directions99, 100. To obtain a colour image, an assembly of three such waveguides is used. Each of them is designed for a different wavelength, as shown in Fig. 4d101. The parameters of the waveguide diffraction gratings for a specific spectral channel, as well as the optical characteristics of the substrate itself, are selected in such a way as to ensure the most efficient light transfer by TIR in the whole angular field102, 103.

The HL 1 waveguide uses three diffraction gratings, as shown in Fig. 4e. The in-coupling grating is necessary to introduce rays into the substrate at a TIR angle. Relay grating changes their direction at an angle of 90° downward to the out-coupling grating104. The out-coupling grating is oriented so that the rays, deviating from it, exit the substrate towards the observer’s eye, forming an eye-box of the required size105.

The principle of dual-channel exit pupil expansion is implemented in HL 2106. The diffractive waveguide of HL 2 glasses is shown in Fig. 4f. The symmetrical structure provides a wider FOV by splitting the input light into two symmetrical components propagating in opposite directions in the waveguide.

It is important to note that headsets also have different image sources. The MS HL 1 uses a Himax 1366 × 768 LCoS field sequential colour microdisplay107. The MS HL 2 glasses use laser beam scanning display 1440 × 936108 as a display engine.

-

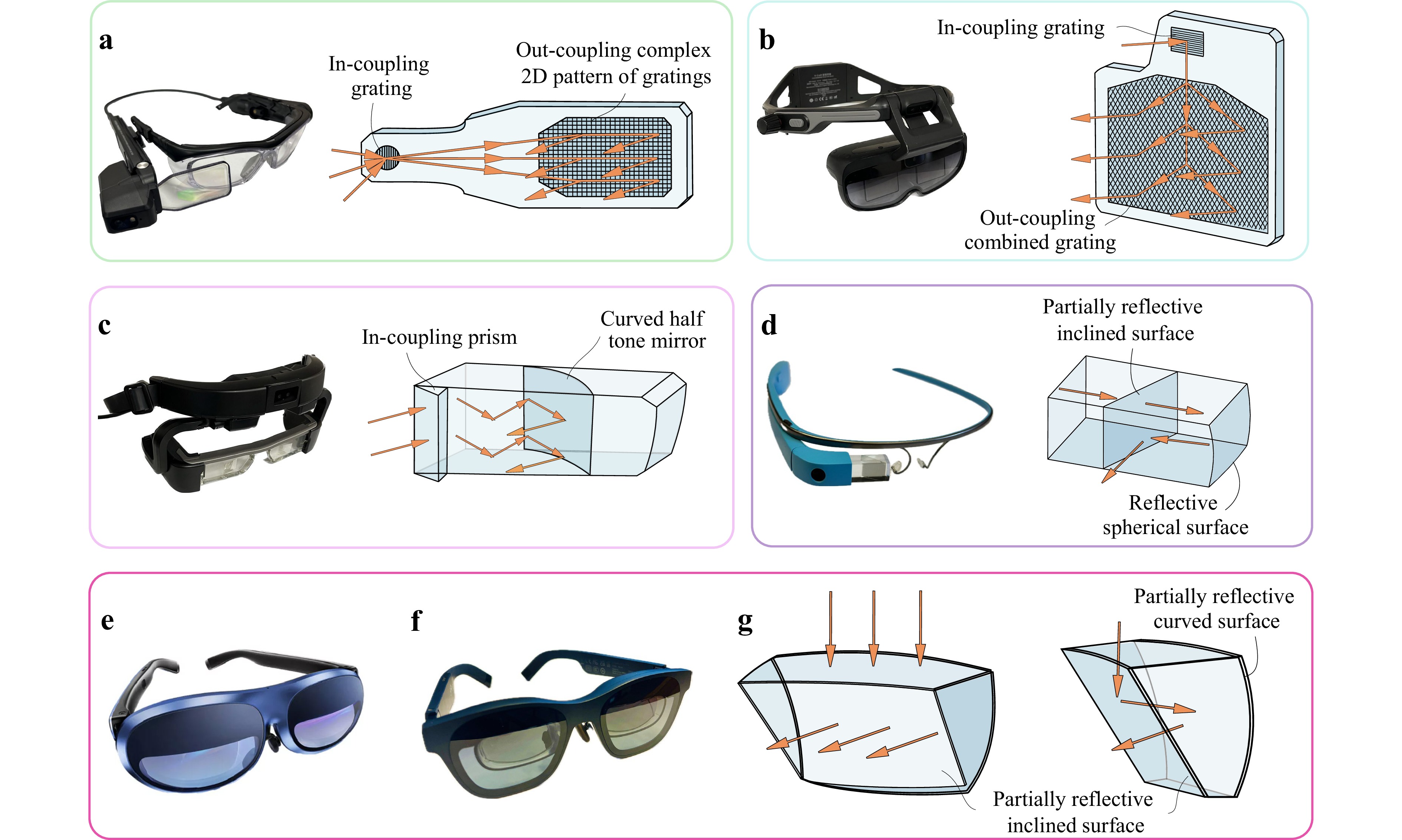

The Vuzix M4000 is a monocular device in which the display is housed in the frame of the glasses on one side, and the battery on the other, as shown in Fig. 5a. The developers position this headset as universal corporate-class glasses, productive and highly transparent. The advantage of the device is the ability to hand tracking, control gestures, and provide “hot” battery replacement109. Also, the same monocular sample can be used for both the left and right eyes.

Fig. 5 AR headset and the scheme of light propagation: Vuzix M4000 a, Rokid X Craft b, Epson Moverio Pro BT-2200 c, Google Glass EE XE-C d, Rokid Max e, XReal Air 2 f, birdbath design for Rokid Max and XReal Air 2 g.

Vuzix, like Microsoft’s headsets, creates virtual images using diffractive waveguides, but with a different grating configuration. The developers focused on ensuring that the image produced by the optical system was bright enough in the farthest zone from where the light entered the waveguide110.

The out-coupling grating is a digitally synthesised complex 2D pattern optimised to obtain the required brightness characteristics in each part of the output linear FOV, as shown in Fig. 5a. In practise, it is difficult to achieve uniform brightness of the image, so the out-coupling grating consists of many discrete zones (frames) that have different characteristics according to the parameters of the relief profile111.

The optical scheme of the Vuzix M4000 combines two thin waveguides (about 1 mm) for full-colour implementation. Two diffractive waveguides are required for different spectral channels, as in the HL, but the provided diagonal FOV is 1.85 times smaller. The headset uses a full-colour DLP display (854 × 480) as an image source112.

-

Rokid X Craft AR glasses, shown in Fig. 5b, are one of the leading industrial AR glasses compatible with standard safety helmets. The headset is adapted for use in difficult conditions: oil and gas pipelines, electric power, aviation, railway transport, and other industries. The device enables voice control even in noisy environments and provides modern connectivity standards for use in real-time IoT applications113. For ease of use, the design of the headset allows the information display system to be folded up.

To display images, Rokid X Craft uses binocular diffractive waveguides with 40° FOV. The optical scheme, as in the two previously described types of headsets, uses combinations of diffraction gratings, as illustrated in Fig. 5b.

It seems plausible to assume that the waveguide used in these glasses was inspired by WaveOptics’ Vulcan design114. The waveguide contains two diffractive optical elements: an input diffraction grating and an output component, which also performs the function of two-dimensional pupil magnification. As shown in Fig. 5b, the grating configuration is more similar to the Vuzix 4000, but provides a larger linear eye-box (19 × 15 mm). According to our assumption, the optical engine in the Rokid X Craft is a Saturn 2 DLP projector with a resolution of 1280 × 720, also produced by WaveOptics.

-

The Epson Moverio Pro BT-2200 headset, shown in Fig. 5c, is an OST smart headset built for industrial needs where protective helmets are mandatory, such as the Rokid X Craft.

The virtual image is formed using a different principle, a flat waveguide combiner with a single curved extractor mirror, as shown in Fig. 5c. Compared to implementations on diffractive waveguides, the OST display with a halftone mirror functions as a single-exit-pupil system without pupil replication85. The production technologies of such optical systems are much simpler than diffractive waveguides, so these headsets can cost several times less in comparison with headsets based on diffractive waveguides.

In this case, the FOV is about 23° horizontally and provides sufficient brightness for comfortable viewing of images in 2D and 3D modes in any lighting conditions. The display uses an LCD panel with qHD resolution (960 × 540). With a physical size of 0.42 inches, the developers claim that the virtual screen is 64 inches at a virtual viewing distance of 4 m.

-

The GG EE XE-C headset, shown in Fig. 5d, features a compact prism monocular mounted on a frame with nose pads115. It is more convenient to use it in combination with prescription glasses or sunglasses.

The optical scheme is based on a reflective surface and, unlike previous options, does not use waveguide light propagation. The monocular functionally consists of two main optical components: a spherical mirror and a beam splitter, as shown in Fig. 5d.

To form an image, the device uses a Kopin LCD display with backlighting and a resolution of 640 × 360, which is mounted on the arm85. The optical beams are collimated by a spherical mirror and then redirected to the user’s eye using a 50/50 beam splitter. The diagonal FOV is 13°. The projected image is similar in perception to a 25-inch screen located at a distance of 2.5 m.

-

The latest commercial headsets under study, Rokid Max116 and XReal Air 2117, are shown in Fig. 5e, f. These products are constructed using a technology known as the ‘birdbath’ design, which incorporates two reflective optical components: a curved mirror and a half-reflective mirror, as illustrated in Fig. 5g. The technology is based on the same principle used in the Epson Moverio Pro BT-2200 and GG XE models, but with an air gap between the reflective components, as described in118. The optics project light from the self-luminous microdisplay onto an inclined flat surface, maintaining an angle of 45°. The light is directed to a curved mirror, reflected from the user’s eye, and then re-passes through an inclined surface. The design is compact while maintaining good overall image quality. It offers a very wide FOV of over 50°. The FOV is 50° and 46°, respectively, for the Rokid Max and XReal Air 2 models. Both of them are equipped with Full HD Micro-OLED image sources. A downside to the birdbath design is the loss of light. It has a privacy issue because other people can see the display from the outside, from all directions.

-

This section is devoted to the analyses of AR headsets and the specifics of their use in manufacturing. Based on the data provided by the manufacturers, a comparison of the main characteristics of the devices was carried out, presented in Table 2.

Vuzix M4000 MS HL1 MS HL2 Rokid X Craft Epson BT-2200 GG EE XE-C Rokid Max XReal Air 2 Optics Type of system Monocular Stereoscopic Stereoscopic Stereoscopic Stereoscopic Monocular Stereoscopic Stereoscopic Display technology Waveguide Waveguide Waveguide Waveguide Mirror Mirror Birdbath Birdbath Display resolution, pixels 854 × 480 1366 × 768 1440 × 936 1280 × 720 960 × 540 640 × 360 1920 × 1080 1920 × 1080 FOV, ° 28 35 52 40 23 13 50 46 Brightness, nits 1000 350 (measured) 500 (measured) 1600 1000 (measured) 300 (measured) 600 500 colour depth, bit 24 16 16 24 24 − 6 8 System Processor Snapdragon XR1 Intel Atom x5 Snapdragon 850 Amlogic A311D TI OMAP 4460 TI OMAP 4430 − − Cores 8 4 8 6 2 2 − − Frequency, GHz 2.52 1.04 2.96 2.2 1.2 1.2 − − RAM, GB 6 2 4 4 1 1 − − Internal memory, GB 64 64 64 128 8 16 − − Battery Capacity, mAh 1000 16500 5660 10000 2480 780 − − Battery life, hours 2 2 2 8 4 4 − − Buttons/touchpad ● ● ● ● ● ● ◐ ○ Controls Voice ● ● ● ● ○ ● ● ○ Gestures ○ ● ● ● ○ ○ ○ ○ Camera Resolution (photo), Mp 12.8 2 8 8 5.1 5 − − Resolution (video), pixels 3840 × 2160 1408 × 792 1920 × 1080 1920 × 1080 1920 × 1080 1280 × 720 − − FPS (video) 30 30 30 30 60 30 − − Number of cameras 1 5 5 2 1 1 0 0 Connectivity Wi-Fi ● ● ● ● ● ● ○ ○ LTE ○ ○ ◐ ● ○ ○ ○ ○ Bluetooth ● ● ● ● ● ● ○ ○ GPS ● ○ ○ ● ● ○ ○ ○ USB USB-C micro USB USB-C micro USB/ USB-C micro USB micro USB USB-C USB-C Others Compatibility with PPE ● ○ ○ ● ● ○ ◐ ◐ Standalone ● ● ● ● ◐ ● ○ ○ Noise Cancellation ● ◐ ◐ ● ○ ○ ○ ○ Protection level IP 67 IP 65 IP 65 IP 66 IP 54 IP 53 Not certified Not certified Adjusting the display position ● ○ ● ● ● ◐ ○ ○ Weight, g 222 579 566 600 270 50 75 72 Table 2. Summary of AR Headsets.

It should be noted that the brightness values of some headsets are not specified in the datasheets. Accordingly, additional measurements were carried out. The weight of the Epson headset is indicated only for the head part without the external unit.

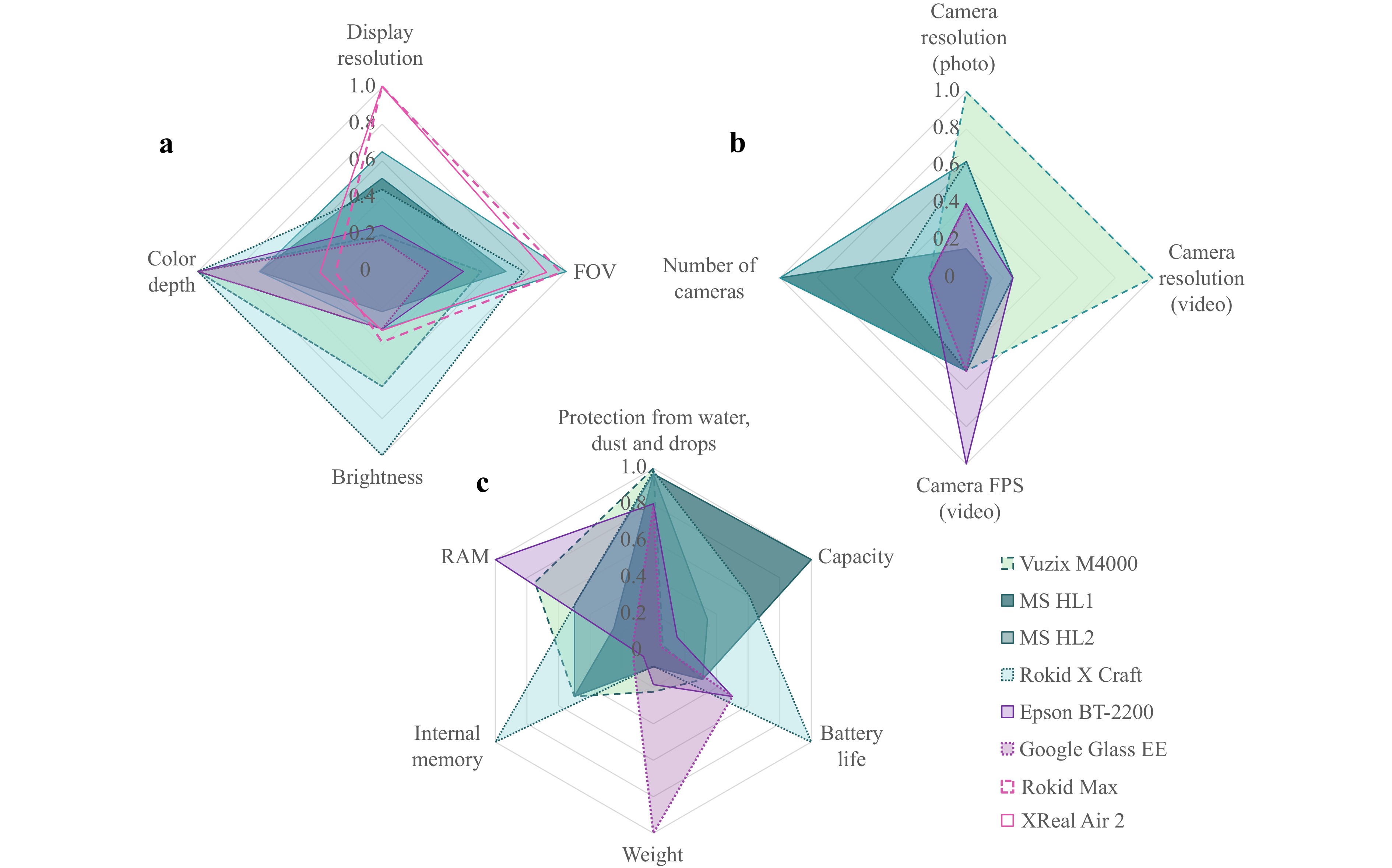

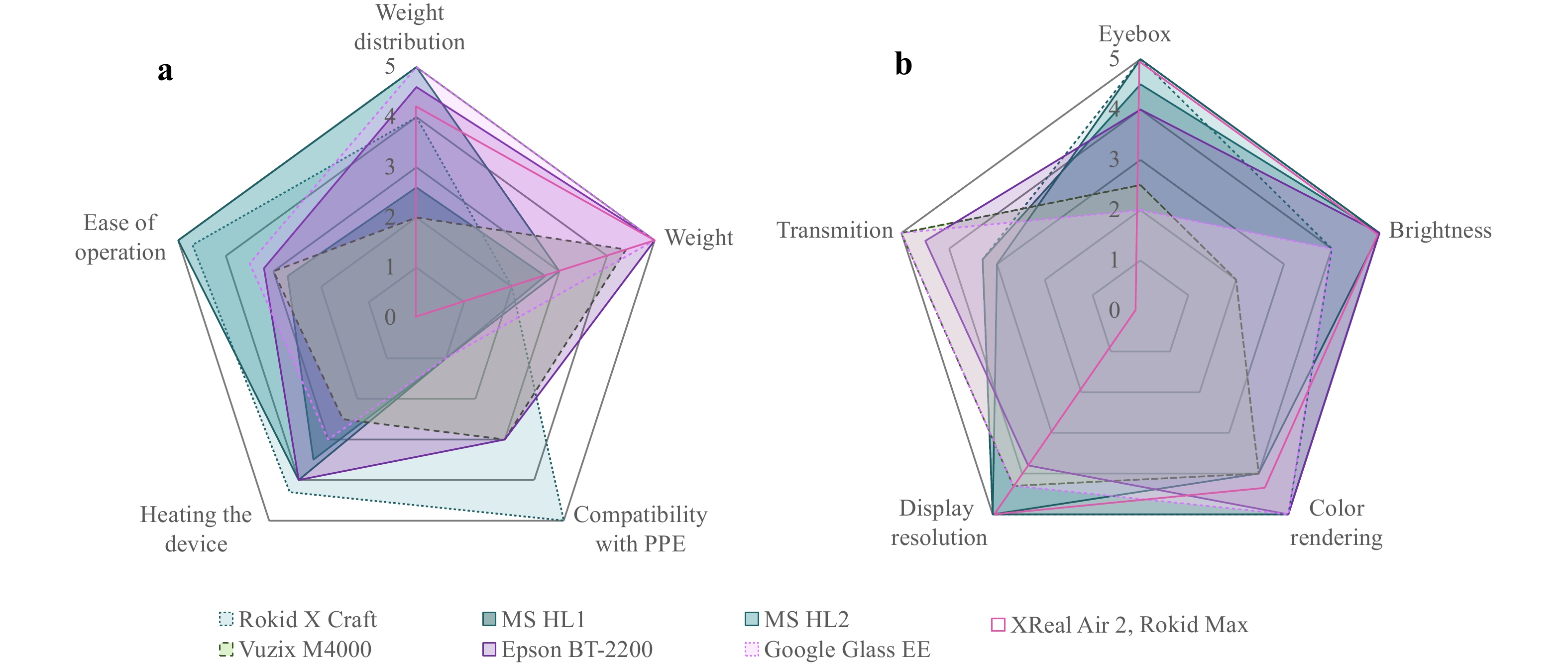

Fig. 6 shows diagrams for easy comparison of headsets. The value 1 for each diagram is taken as the best value of the selected parameter among all considered headsets, for example, the maximum FOV value, and the remaining values are recalculated relative to this value based on the quantitative parameters according to Table 2. The closer the value of the selected parameter to the top in the petal diagram, the better.

Fig. 6 Diagrams for analysing AR headsets Vuzix M4000, MS HL1, MS HL2, Rokid X Craft, Epson BT-2200, GG EE XE-C, Rokid Max, XReal Air 2 based on datasets: a comparison of optical parameters, b comparison of photo and video shooting capabilities, c comparison of other user parameters.

The features of the optical scheme of the headset establish the parameters of the image quality delivered to the user, as illustrated in Fig. 6a. Therefore, it is advisable to begin a comparative analysis with an examination of optical parameters. The optical capabilities were compared according to the following parameters: display resolution, colour depth, FOV, and brightness. It can be seen that the best FOV is provided by headsets that have diffractive waveguides as displays (Hololens and Rokid X Craft), as well as with Birdbath architecture (XReal, Rokid Max). The FOV value of Epson and especially GG is strongly limited by the features of the optical scheme design, and it is problematic to improve it without significantly increasing the dimensions The highest resolution is also present in black XReal, Rokid Max, Hololens and Rokid X Craft, i.e. high detail of the output objects is provided, which is important when observing complex assembly units, diagrams, drawings or text documents. The highest brightness is claimed for Epson, Rokid and Vuzix headsets, which potentially allows them to be used in illuminated rooms.

Fig. 6b shows the camera parameters for recording the surrounding space: camera resolution (photo), camera resolution (video), frame rate (FPS), and number of cameras. The high resolution of the camera is important for recognizing and remotely monitoring small objects. The Vuzix headset has the best resolution. It should be noted that HL has a number of cameras up to 5, among which there are cameras for environmental recognition, time of flight camera. This allows HL to be used in more complex cases.

Fig. 6c shows other important user parameters for comparison: capacity, battery life, weight, internal memory, random access memory (RAM), and protection from water, dust, and drop resistance. If we consider these parameters, the situation is essentially the opposite. For example, GG has a small weight, followed by Epson and Vuzix. In this case, the closer the value in the diagram is to 1, the less the weight, i.e. the weight of the lightest headset is taken as the value 1. Thus, it is obvious that the higher the requirements for image quality parameters, external camera, battery capacity, and computing resources of the headset, as seen in the case of Hololens or Rokid X Craft devices, the more its weight. The corresponding diagrams are also compiled based on user estimates for the parameters described above.

Given that the AR headset is a human-centric device, an analysis of it must take into account the features of the human experience, which will be subjective. To increase the reliability of this analysis, a focus group survey of several people was conducted. The expert group included employees of industrial enterprises (11 people) who have been working there in their specialty for at least 2 years and already have experience in assembly, repair or maintenance using AR technologies. Moreover, two experts are co-authors of the review. The age of the experts ranged from 23 to 46 years, including 8 men aged 23 to 46 years (average age – 34.5 years) and 3 women aged 26 to 37 years (average age – 31.5 years). All experts are well-familiar with augmented reality systems and don’t use corrective glasses. It is notable that there are 27% of the experts being female identifying the issue of gender imbalance in the survey. This limitation aligns with the current status of industrial production teams. The manufacturing sector’s share in women’s employment is estimated around 25–30%119, 120. Women are still underrepresented in the manufacturing sector, but sociologists recognise the growing role of women in Industry 4.0 or Smart Manufacturing121. As a result of the analysis, it turned out that female responses in comparison to male ones were similar on average and differed mostly in terms of ease of operation, weight, and weight distribution. For instance, women rated the ease of operation of Hololens 1 significantly lower than men. Meanwhile, Epson BT-200 glasses were much easier to operate with for women, regardless of the control was realised by additional block. Weight and weight distribution were assessed by them more strictly, for example, the weight distribution rate of Hololens 1 was lowered due to significant pressure on the nose bridge and neck tiredness in case of long-term work.

Users were first provided with test images to evaluate quality, colour rendering, etc., and then offered a small case for assembling the mechanism to assess the operating comfort of the headset. Depending on the FOV in the second case, the level of content varied (from simple step-by-step text instructions to the output of three-dimensional models and support from a remote expert). The total time required to finish assembling the mechanism, i.e. the time spent working with the AR headset, was between 40 and 50 minutes. After this, users were offered a questionnaire with a rating scale from 0 to 5, which is essentially a Likert scale122, presented below. For a Likert scale, the questionnaire postulates a statement and asks users to rate their level of agreement with the statement123.

The user survey questionnaire comprised the following questions:

$ {\bf{Q1}} $ How do you rate the simplicity and convenience of interacting with the headset?

$ {\bf{Q2}} $ How much does the heating of the device feel during operation?

$ {\bf{Q3}} $ How noticeable is the weight of the headset?

$ {\bf{Q4}} $ Are you satisfied with the weight distribution of the headset?

$ {\bf{Q5}} $ Is it convenient to use the headset while working with PPE?

$ {\bf{Q6}} $ Was the headset bright enough?

$ {\bf{Q7}} $ Are you satisfied with the screen resolution?

$ {\bf{Q8}} $ How comfortable was the eyebox and how well was the image adjusted for the eye?

$ {\bf{Q9}} $ Are you satisfied with the colour rendering? How do you assess the visibility of colour distortions and aberrations?

When using a rating scale from 0 to 5, the response options are as follows: 0 — completely dissatisfied/very low, 5 — completely satisfied/very high. The user must provide the most appropriate rating for each question.

This approach is quite typical for evaluating such devices, their usability and user interface, etc., as described in62, 73, 78, 124, 125. This is important because objective parameters do not always reflect the features of interaction with the headset, its convenience, or the visual quality of the image. Indeed, a user’s opinion of a headset is a subjective experience of the user, which can help us further improve the way it displays and interacts, as well as incorporate feedback into the design of similar devices.

In preparing the questions, questionnaires from62, 78, 124, 126 were partially used. They mainly relate to the overall impression of using augmented reality technology in general78, 124 or, for example, in comparison with paper documents126, as well as its convenience and potential for further application62. Questions about the comfort of wearing, ease of operation, and bulkiness of devices are found in78, 124, the readability and visibility of virtual objects are mentioned in the questionnaire62, 78. This review proposes a group of questions that reveal the above in more detail. For example, the readability and quality of virtual content are analysed based on questions about resolution, brightness, and colour rendering; the convenience and comfort of wearing are related to weight, its distribution, the convenience of individual adjustment, and possible discomfort when the device is heated, etc.

In this context, an attempt was made to determine the relative strengths and weaknesses of each headset in order to identify the option and composition that will provide optimal performance in each of the standard cases. For a more correct subjective comparison of image quality, users were presented with identical test images with assembly units, drawings, and a remote expert/video call interface. Users rated each parameter. The average values based on the survey results are shown in the diagrams in Fig. 7.

Fig. 7 Diagrams based on user ratings of AR headsets Rokid X Craft, MS HL1, MS HL2, Vuzix M4000, Epson BT-2200, GG EE XE-C, Rokid Max, XReal Air 2: a comparison of user parameters, b comparison of optical parameters.

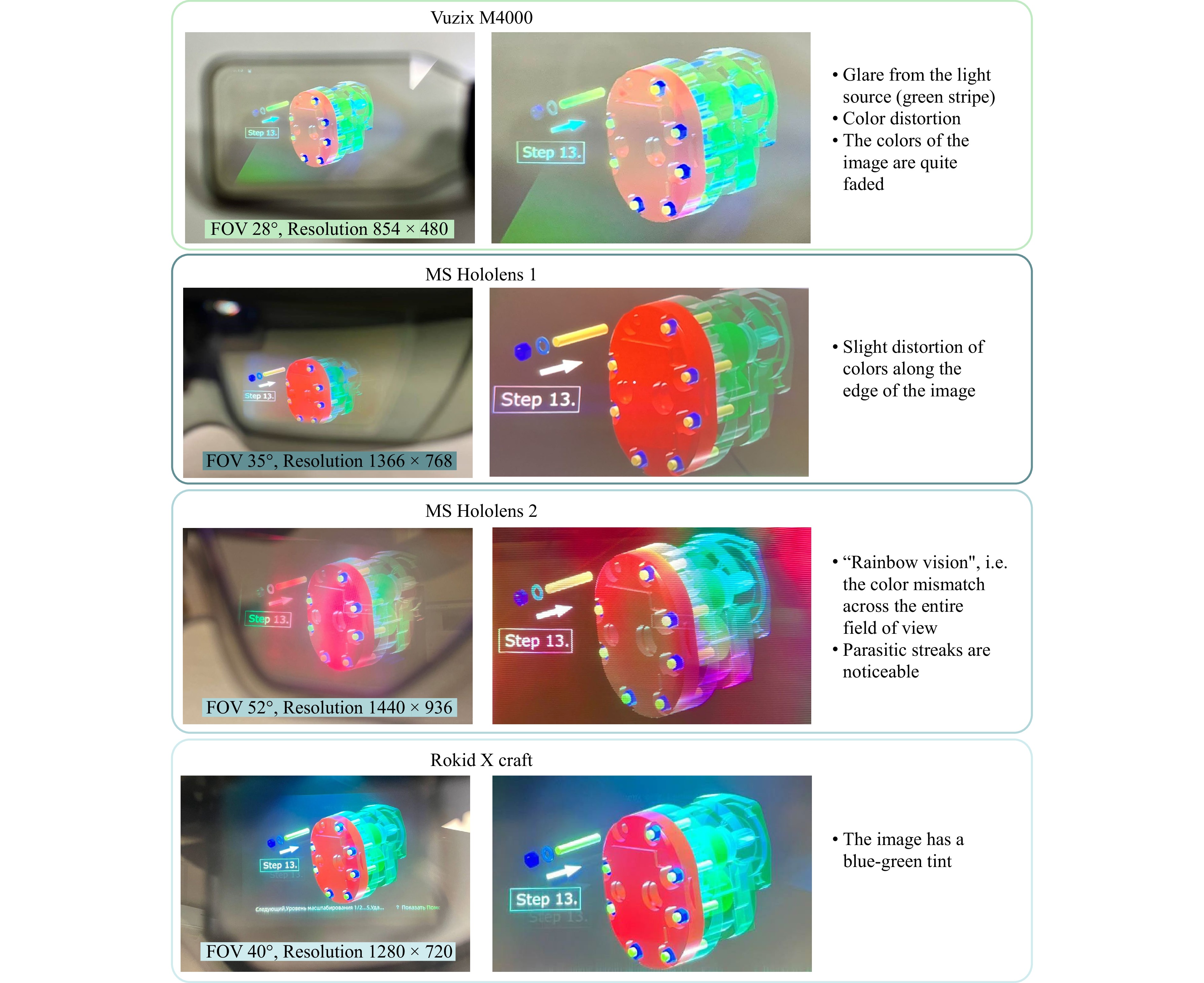

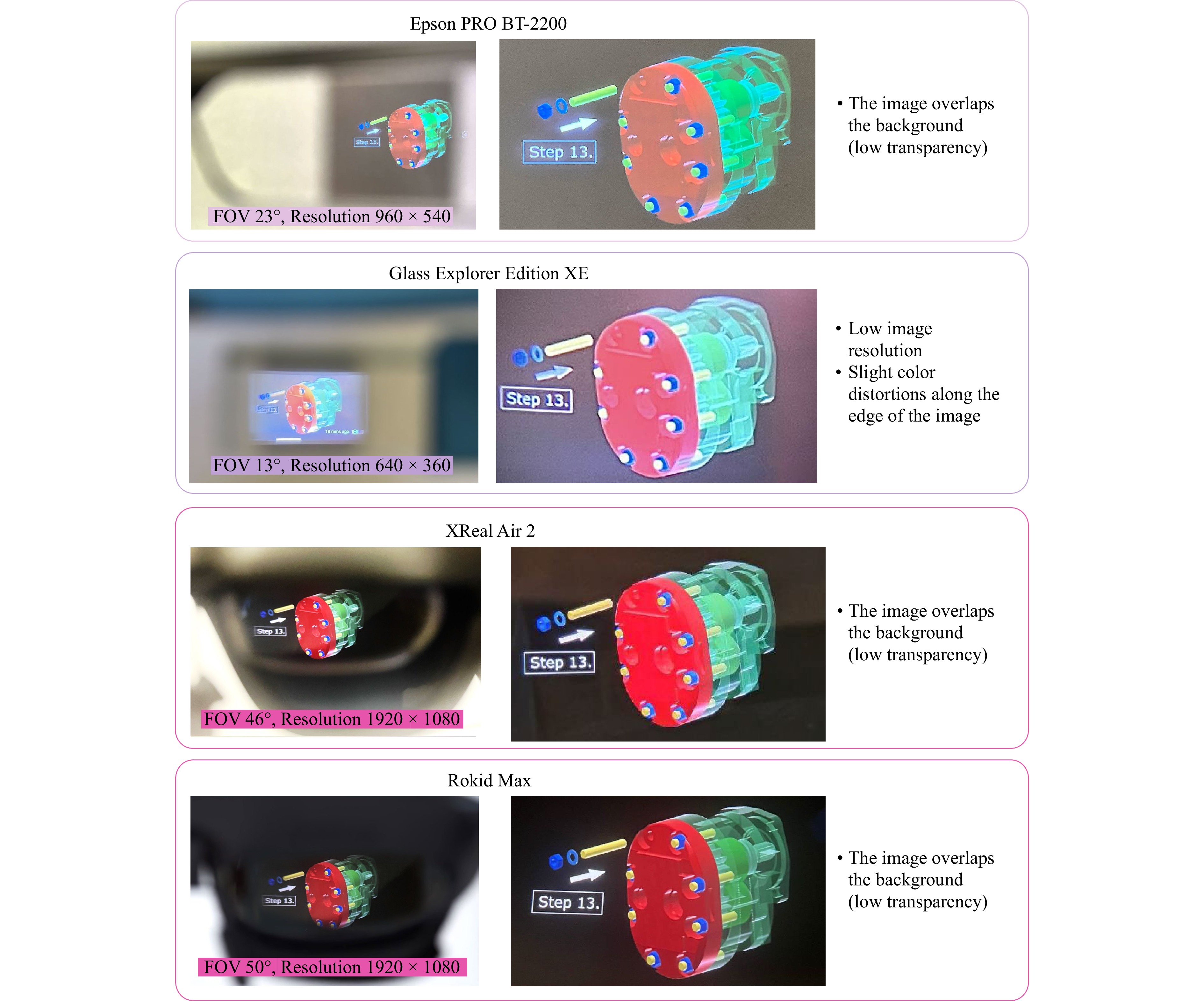

As can be seen from the diagrams, headsets with waveguide-based displays have a much higher eye-box than the rest because the principle of pupil multiplexing is implemented, which means that the requirements for individual adjustment of the device to the user’s eye are reduced, and the device becomes more convenient to use. This observation has been documented by users, indicating that waveguide schemes are the most preferred option among others in terms of implementing OST displays for user convenience and generating AR images. GG headset have the smallest FOV and eye-box, which leads to some inconveniences in setting up the device and is noted by users as the main drawback. However, it is important to note other facts. Diffractive waveguides cause colour distortions, as can be seen from Fig. 8. Furthermore, waveguide-based schemes have low radiation transmission efficiency from the display to the eyes due to the presence of several diffraction gratings with limited efficiency. Thus, such schemes use LCoS or DLP displays together with a bright LED backlight source, which leads to a strong heating of the device, which is also noted by users, as can be seen in Fig. 7a. Additionally, such devices can use a light-absorbing visor, but even its presence does not always allow you to get a contrasting picture in brightly lit rooms or outdoors on a sunny day, which is noted by users working with HL 1 and Vuzix M4000. Besides, unlike GG EE XE and Epson PRO BT-2000, the Rokid X Craft, MS HL1, and MS HL2 headsets received the lowest scores from users for their weight. These contradictions once again confirm the idea that the model and parameters of a typical headset should be determined based on the application case.

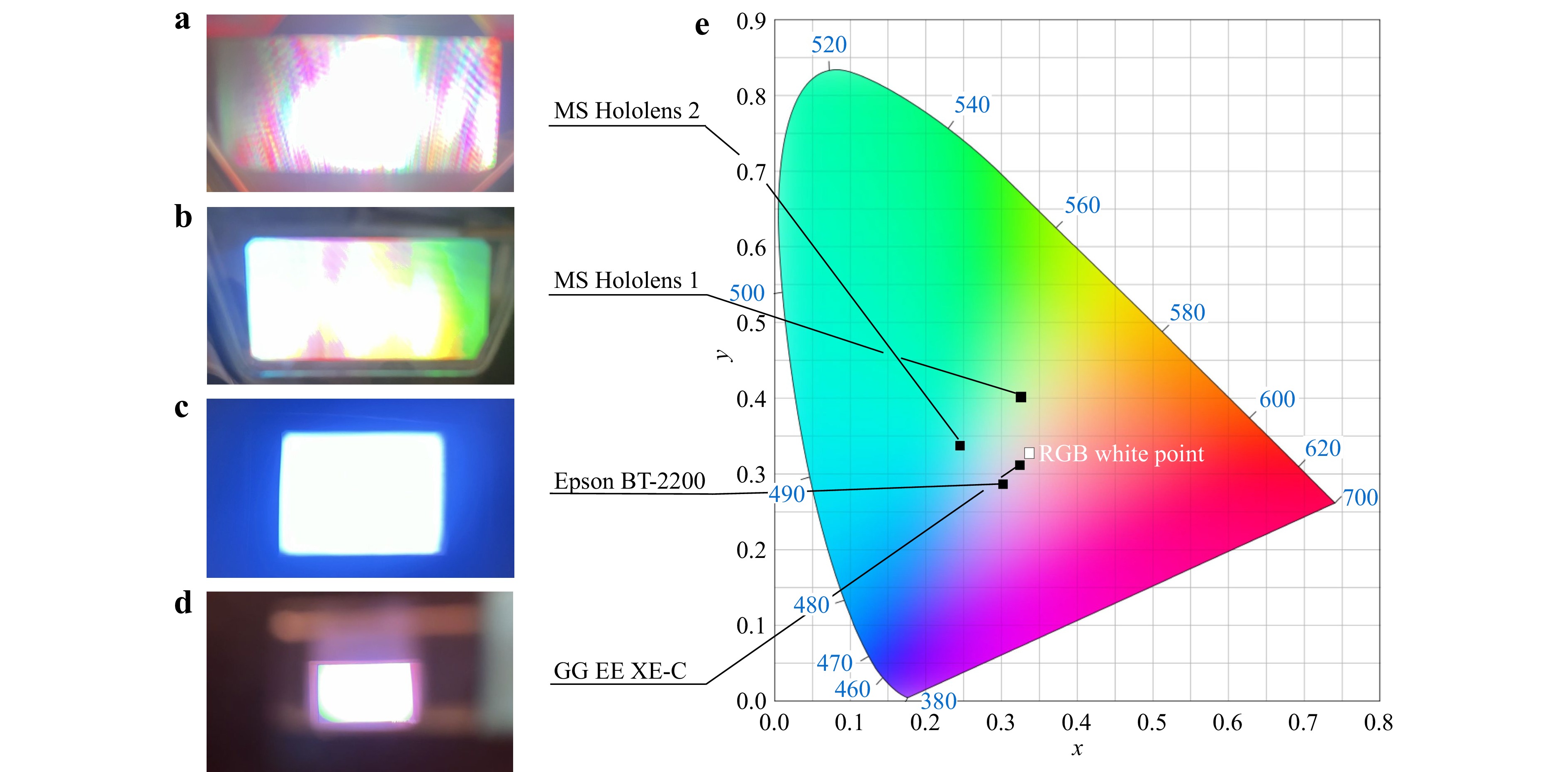

Fig. 8 shows typical images of the assembly unit, which were displayed by the user using various models of glasses based on diffractive waveguides. To compare the image quality in displays based on the beamsplitting principle, let us refer to a similar illustration on Fig. 9. The aim of this demonstration is to illustrate the impact of different optical schemes on image quality, defects, and other image artefacts. This may be important for both operators and device designers, as image quality and visual perception features may be critical in the selection of the most appropriate type of wearable display. The following observations and conclusions can be made. Firstly, colour errors are typical for devices based on diffractive waveguides, this is especially noticeable in the MS HL2 headset. Since the white colour is the result of mixing green, blue, and red, these errors are most noticeable for it, i.e. the white image is transmitted with slight colour, as can be seen from Fig. 8. The analyses of chromatic coordinates for white in the CIE XYZ colour space is additionally shown in Fig. 10. For two devices based on diffractive waveguides, the white point deviates significantly from the ideal one. While for implementations based on reflective surfaces, this correspondence is quite close (especially in the case of GG). The measurements were carried out using the Jeti Spectraval 1501 spectroradiometer when registering the chromatic coordinates of a white background image output using an AR headset.

Fig. 10 White colour images: a MS HL 2, b MS HL 1, c Epson BT-2200, d GG EE XE-C, e Displaying the white points of the headsets on the CIE chromaticity diagram.

Secondly, parasitic glare is sometimes present due to the diffraction of radiation from external lighting sources on diffractive waveguides. The advantage is that the image in such systems fills a large area of the waveguide, which reduces the adjustment requirements, and also provides a comfortable overlap of the user’s FOV. The perceived image quality in systems based on reflective surfaces (Epson, GG, XReal and Rokid Max) differs for the better due to the absence of chromatic aberrations caused by diffraction elements, as illustrated in Fig. 8. But there are also disadvantages, for example, due to the presence of a reflective coating in Epson, XReal and Rokid Max, the virtual image output area darkens the surrounding space, as can be seen from Fig. 9.

When using a micro-OLED display127 (as in XReal and Rokid Max), a reduction in size is achieved while maintaining acceptable image brightness, unlike OLED, LCD, LCoS, etc., as evident from the study of new headsets. Thus, these displays may well become one of the main types of displays for AR devices in the future, providing not only high image quality but, also a compact device form factor.

Nevertheless, it is the convenience of working with virtual content and the size of the area of its overlay on the surrounding space that is decisive for many users, therefore, when considering standard images in the form of drawings and virtual 3D models, preference was also given to Hololens and Rokid devices.

Next, a series of parameters that define subjective assessments of users when working with headsets were considered. These include the following: the weight of the headset, ease of operation, and the ability to remove or lift the display during operation, as well as compatibility with various personal protective equipment (PPE), the wearing of which is mandatory in some industrial enterprises, etc. These parameters and reviews of each device are described below.

The GG headset has the lightest weight among those considered, a convenient form factor combined with the possibility of compatibility with various PPE. The control is carried out mainly using a touchpad, despite the fact that the glasses have voice control, as well as winking (in which the device, for example, can take a photo). This is due to the fact that voice commands are not always recognized quickly and accurately enough. Using a touchpad is not always convenient, especially when working with gloves, and also from the point of view that the user’s hand will be busy all the time, while there is a high chance of making a mistake. For example, to delete a file in GG, just double-tap the headset frame. In addition, the frame has a very low weight and is fragile, which can lead to skewing in the direction of the optical element, despite its low weight. At the same time, the display easily adjusts to the eye, and due to its low weight, there is no pressure on the bridge of the nose. Another feature of the headset is a weak battery, which heats up during prolonged use of the headset, causing discomfort to the user. However, the main disadvantage of the headset is the size of FOV, which does not exceed 13° diagonally. Thus, users note a rather small virtual screen, which, due to its design features, is located in the upper right part of the FOV and it is not very convenient to “switch” to it during operation.

Users have noticed the following design flaws of the Vuzix M4000 headset: the connecting cord between the two parts of the headset (the main part and the battery pack) interferes with the user during the workflow and limits his mobility. There is also a slight imbalance in weight, while the glasses put pressure on the bridge of the nose, which makes it difficult to use them for a long time. The eye-level adjustment is not sufficient, making it difficult to adjust the device so that you can see the entire display, making it less comfortable to work with. The Vuzix M4000 has weak voice and touch controls, as well as several buttons, but they are located in the upper part of the case, so they are difficult to reach when working in a helmet. The advantages of this headset are good compatibility with PPE, the ability to connect an external rechargeable battery to increase the working time with the device, as well as low weight (less than 200 g). In general, it can be concluded that for performing simple cases and getting acquainted with AR technology at the enterprise, it is possible to pay attention to this device.

The Epson Moverio BT-2200 headset has one major drawback: the external unit with a cord that goes to the head of the device. It also lacks voice control (no microphones). In the industrial segment, any external equipment is a limiting factor that restricts the range of movement of personnel while they are in workwear. However, it is important to note that the external unit facilitates intuitive control of the glasses, as it incorporates a touchpad that simulates a computer mouse. The headset has bright displays, excellent colour rendering, lift-up screen capability, and compatibility with PPE. One potential drawback of the displays, as observed by some users, is the inability to individually adjust the base of the eyes. This is because the screens for the right and left eyes may shift relative to each other, requiring effort to adapt them into one. This effect is probably due to the smaller eye-box in such an optical design in comparison to that of waveguides that implement exit pupil expansion. Furthermore, some users may experience difficulty due to the frames of glasses that enter their FOV. However, with practice this can be overcome. Therefore, the device can be used in certain cases, such as commissioning of equipment.

The Rokid X Craft, like the Epson Moverio BT-2200, is a binocular device. As stated above, it has satisfactory image quality. It is of paramount importance that AR glasses are equipped with an integrated SIM card module and are 5G compatible, which is essential for remote employees and allows them to stay connected "in the field". The device offers both good voice and gesture control, as well as mechanical control utilising a rotating wheel and buttons, which are large in size and therefore convenient when working with gloves.

The device’s integration with a safety helmet, capacious battery, and ability to operate in various environmental conditions are also notable advantages. The system does not necessitate the connection of additional units, processors, or computers, thereby exemplifying a true standalone solution. The device’s primary disadvantage is its weight, which is approximately 560 g. The visor with OST displays can be pulled up, but in this case, the glasses begin to hang the user’s head down. The manufacturer also offers the Rokid Glass 2 headset, which is light weight, has good brightness and image quality, but the use of an external wearable unit and the complexity of its configuration, as well as weak voice control, render this headset less suitable for industrial use. MS HL 1 and 2 headsets, when used as standalone devices (without connecting external units), currently have some of the best displays in terms of FOV and brightness. However, despite the higher resolution of MS HL2 displays compared to MS HL1, the latter has the better image quality and colour rendering due to the use of a different projector type. In terms of device control, the MS HL1 offers a range of input options, including gestures and voice control, as well as adjustment buttons for brightness and sound volume. The effectiveness of the noise reduction feature is less than that of the Rokid X Craft model. The MS HL1 is not as intuitive in regards to gesture controls when compared to the MS HL2. The latter employs gestures that are perceived as being more natural in terms of user control. The headsets are equipped with high computing capabilities, exceeding those of analogues. The MS HL2 headset stands out due to its implementation of genuine AR technology, which enables users to position virtual objects and screens within their surroundings. This capability is not found in other devices. However, the battery capacity is a disadvantage: the operating time is about a few hours, but in complex cases.

The MS HL1 headset does not have the ability to change the display position, unlike the MS HL2. However, when lifting the display in MS HL2, there is a problem related to weight distribution, i.e. the headset exerts pressure on the head. The MS HL1 headset is partially helmet compatible, which is not the case with the MS HL2, but the product has very good potential, especially since the Trimble model adapted for a protective helmet has already been released, but we have not had the opportunity to test this headset. As for the case of corporate training or work in assembly shops and on production sites where PPE is not required, Microsoft headsets, and especially MS HL2, are a ready-made solution that is already being actively implemented. At the same time, the weight of the MS HL2 is more than 500 g, but this is quite justified in terms of a set of sensors and computing power, because the device is a powerful computer capable of implementing almost all the cases necessary in industrial production. This once again indicates that when choosing a headset, it is necessary to look for compromises between the parameters required for this case and computing capabilities.

XReal and Rokid Max headsets have large FOV, high image quality, a compact form factor of regular glasses, and low weight. Rokid Max is still slightly superior to XReal in terms of brightness and FOV value; there is a useful diopter adjustment option. These are important advantages of optical architecture that need to be noted. If the eye base does not match, a blurring effect may occur at the edges of the image. The disadvantages include the light transmission of the headsets, which is very low, and taking into account the presence of additional light filters and frames, the effect of a dark "tunnel" is created and some discomfort when observing the surrounding space. In addition, when displaying additional images in XReal, the surrounding space is almost completely darkened. Despite its lightweight, it puts pressure on the bridge of the nose. Both devices are not "standalone", i.e. require a mandatory wired connection to an external unit or smartphone. Both devices lack a camera, which makes it impossible to perform most application cases in the industrial segment.

However, it is important to distinguish between two aspects here: the advanced optical scheme and the headset built on its basis, possessing a set of functional capabilities that determine the scenarios of its use. For example, the absence of a built-in camera in XReal Air 2 or Rokid Max significantly limits the range of possible application cases (remote expert, video surveillance of operations, intelligent assistance during assembly, etc.). Therefore, even with an advanced optical scheme featuring an expanded FOV, compact form factor, and light weight, they are currently unsuitable for most industrial applications, although they may be the preferred choice for users in the consumer segment. Currently, they can only be used for certain cases of workforce training (where a camera is not required) or for quick display of drawings, instructions aiming to replace paper-based information carriers. Nevertheless, modifying these and other modern headsets for the industrial segment and seeking alternative ways to overcome design flaws can open up new solutions and applications, as well as elevate industrial AR headsets to a completely different level. This is why the article presents typical requirements for users working in the industrial sector, making it useful for AR headset developers.

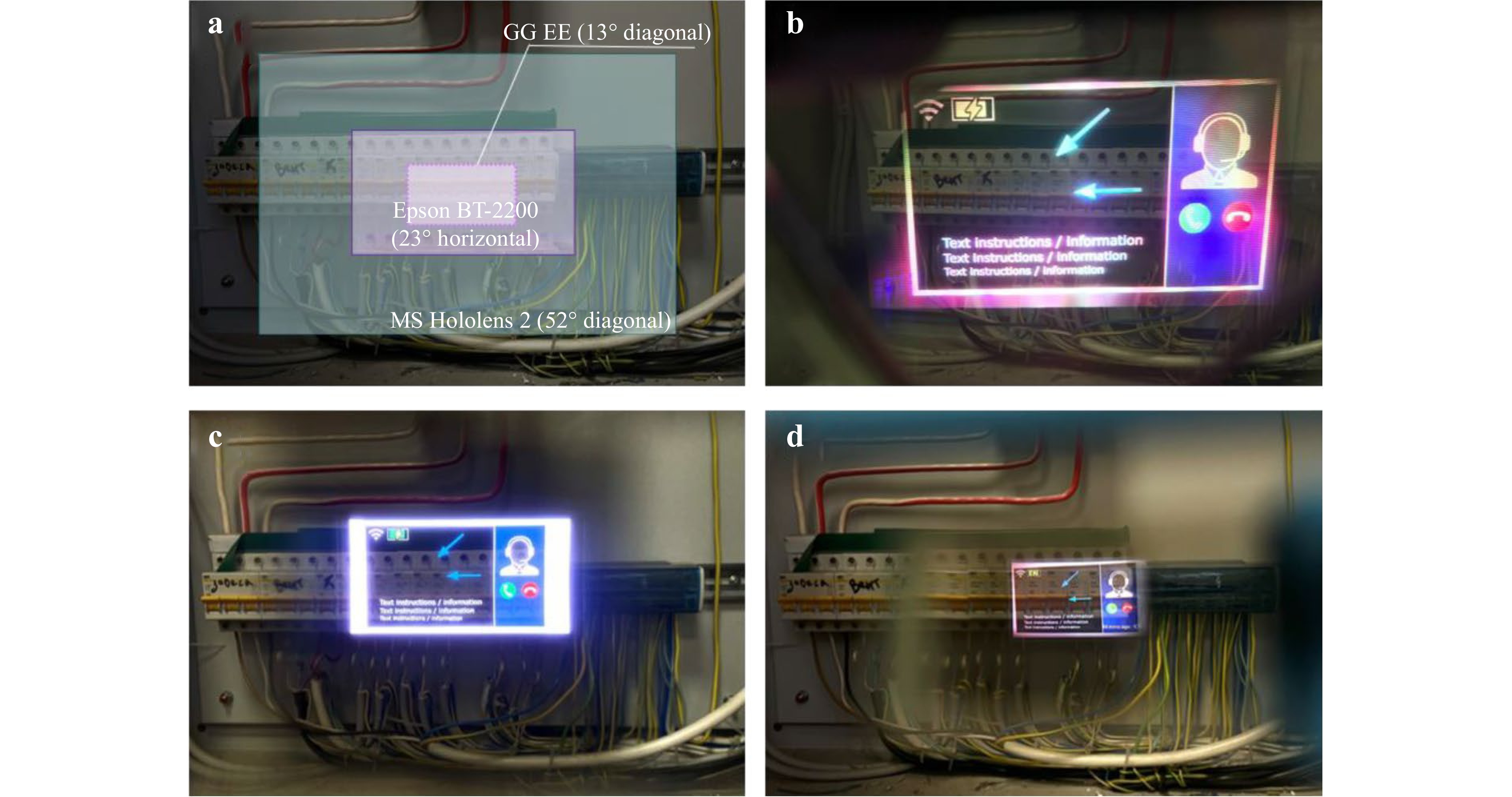

Fig. 11 illustrates the use of three AR devices to implement an enterprise electrical panel maintenance case. Fig. 11a clearly shows a comparison of the FOV of the devices. Fig. 11b, c were obtained when displaying images using AR devices.

Fig. 11 Comparison of the FOV of various AR devices for the maintenance case of an enterprise electrical panel. a The FOV of the headsets is according to the datasheets. b Image output via Hololens 2, c Image output via Epson BT-2200, d Image output via Google Glass EE XE-C.

As can be seen from Fig. 11d, the FOV and image size in GG are quite small. This size is suitable for displaying short hints or a video call, but working with documents, diagrams, or three-dimensional models in such a device is difficult. The largest eye-box and FOV are demonstrated by the HL 2 device in Fig. 11b. The area of interest is covered with additional information as much as possible, hints and images are clear, and working with them is comfortable. At the same time, this headset allows spatial linking of content to the surrounding space. The Epson device is an intermediate case in terms of the size of the eye-box and the FOV. Despite the good image quality, FOV is still small, because only the central part overlaps, and this is not enough when assembling or servicing extended objects, because their parts may not fall into the image output area. In addition, as noted above, the image output area darkens the surrounding space compared to the side areas, which is noticeable in Fig. 11c.

Analysing the privacy and confidentiality of such headsets is a complex task that covers several aspects at once: device development, software platform, application case and enterprise infrastructure that determines data transmission channels, conditions for their processing and storage. As noted in Refs. 128, 129, the device’s camera continuously records without user knowledge, which poses a threat both to privacy and data security for the industry, where the protection of intellectual property and know-how require even more consideration. This statement is confirmed in Ref. 130, where the problem of undetectable video capture by a camera without the knowledge of others, as well as the possible unauthorized collection of information, is noted. In addition, article in Ref. 131 raises the problem of information leakage from a transparent display and its vulnerability to external inference or capture, one of the measures to eliminate which is the installation of a polarizer to block the light from the display. Even when performing cases for their intended purpose using a headset, problems may arise in protecting confidential information. For example, work in Ref. 128 notes that in the case of video communication with a remote expert, images can contain confidential information that comes into the FOV while the worker moves around. Issues of potential and hidden risks posed by headset sensors are raised in Ref. 132, which considers the possibility of 3D scanning of space, as well as in Ref. 129, where the emphasis is on eavesdropping and data breaches due to the built-in microphone. The analysis of headsets for the industrial segment has revealed that the current range of peripheral devices, including cameras, microphones and others, cannot be reduced without adverse effects on both the functionality of the device and its control. Therefore, methods are required to protect headsets in the enterprise, which relate not only to physically restricting access to them, but also to creating software restrictions (authentication).

Privacy work or approaches on mixed reality and related technologies are given in Ref. 132. Extremely useful findings based on the in depth evaluation of the devices in web page security analysis, authentication, user profiling, access control, privacy, and database security are described in Ref. 133. This article presents open data on the authentication methods for various types of headsets, common vulnerabilities and exposure counts, access control (including multi-user mode implementation), data protection mechanisms, and more.

-

So, for each case, it is necessary to work out compromise technical solutions and determine the optimal composition of the headset, as well as to find a balance between its characteristics. The key parameters for each case were established according to a degree of importance as indicated in Table 3. They were determined based on typical cases and their associated characteristic conditions.

Type Display resolution FOV Brightness Camera resolution Inverse mass Performance capacity Battery life Protection Standalone Assembly stationary ● ● ● ● ◐ ● ○ ○ ○ slipway ● ● ◐ ● ● ● ● ◐ ● Repair indoor ● ● ◐ ◐ ◐ ● ● ◐ ◐ outdoor ● ● ● ◐ ◐ ● ● ● ● Maintenance indoor ◐ ◐ ◐ ◐ ◐ ◐ ◐ ◐ ◐ outdoor ◐ ◐ ● ◐ ◐ ◐ ◐ ● ● Remote assistant indoor ○ ○ ○ ● ● ○ ○ ◐ ○ outdoor ○ ○ ● ● ● ○ ○ ● ● Training ● ● ● ○ ○ ● ◐ ○ ○ Monitoring ○ ○ ○ ● ● ○ ○ ◐ ● Quality control ○ ○ ○ ● ● ○ ○ ○ ○ Table 3. Key requirements for headsets depending on the application case.

The size of the headset’s FOV determines the amount and readability of the content displayed to the user. According to this principle, headsets can be divided into several types, namely: with a small, medium, and large FOV. It is notable that there are no standardised FOV values for these products. However, we will consider the case when it does not exceed 20° to be small, medium — from 20 to 40°, and large — over 40°. This classification is based on the observation that the maximum FOV for commercial products does not exceed 55°.

When dealing with a small FOV, it is advisable to display only small text or graphic prompts and instructions to the user (e.g. for monitoring or remote assistance). More complex and detailed content in the form of diagrams, drawings, etc. is poorly differentiated under such conditions. In addition, devices with a small field of view are mostly monocular; the display area for additional information is located on the side, which makes it difficult to perceive complex content.

In the case of a large FOV, the user’s FOV overlap area is the maximum possible for AR devices. This is enough to display any type of content: tips, instructions, photo and video content, drawings, diagrams and three-dimensional models with a high degree of detail, as comfortable as possible for the user. Such devices are suitable for any application cases (especially for assembly, repair, and training, when the requirements for detailed information are high), although in some cases they may be redundant134, 135.

The case of medium FOV is intermediate. While the content detail is not as high and convenient as in the previous one, this version offers the advantage of displaying more structured objects, such as video call window, simplified models or drawings, and photographs, rather than merely limited instructions. This may be suitable for maintenance or remote assistance. Therefore, when developing headset requirements, it is crucial to consider the size of the FOV (and, consequently, the amount of content). Table 3 introduces three gradations corresponding to a large, medium and small FOV, as well as their correspondence for each case.

Display resolution also affects the detail of the displayed content and is related to the FOV. The higher the display resolution, the higher the detail of the displayed information can be provided. It is important to understand that the display resolution should, if possible, be correlated with the FOV, as well as the user’s visual perception characteristics85, when the resolution can reach 0.8 — 1.3 arcminutes (arcmin) in the central region of the FOV. If the resolution of the headset matches or exceeds the resolution of the eye, it is considered high. If it is up to 2 arcmin, it is considered medium. Otherwise, it is considered low. For example, the angular resolution (per pixel) for the GG headset is 1 arcmin; for HL1 and Epson ~1.3 arcmin; for Rockid and Vuzix — 1.6 arcmin.

Ambient lighting conditions are directly related to the headset’s maximum image brightness value. Ambient light levels must be taken into account to spec the target luminance of the AR display to compete with the luminance of the surrounding space118. According to ISO 8995:2002(E), the recommended illumination for industrial workplaces varies greatly depending on the type of task being performed and ranges from 200 to 1000 lux. At the same time, outdoor illumination on a sunny day can reach several tens of thousands of lux, so the brightness requirements for different application conditions are different. A gradation system is to be introduced: for background lighting up to 500 lux, the headset brightness is considered low; for background lighting between 500 and 1000 lux, it is considered medium; and for outdoor conditions (over 1000 lux), it is considered high. In Ref. 85 it is stated that for indoor conditions an OST display luminance of 500 nits is sufficient, and for external conditions — up to 3000 nits. Of course, it is possible to use a light-absorbing filter, but it should be taken into account that it also darkens the vision of the surrounding space, which is not always necessary. For the purpose of contrast estimation, the difference in luminance units can be neglected depending on whether the light received (illuminance) in the virtual image plane above a given area or the light emitted (luminance) by the OST display is measured. If the light meter were placed directly in the eyebox and the output display brightness were calibrated at 500 nit (emitted), the reading would be approximately 500 lux (received).

External conditions also affect the protection of the headset. For outdoor conditions, protection IP65 and higher is required, as well as an extended operating temperature range (from minus 20 to plus 45 degrees Celsius). For indoor production conditions, the protection class is lower.

The weight of the headset directly affects the comfort and duration of its wearing without any tangible consequences for the user. In Ref. 136 it is noted that the wearing time of a headset weighing 500–600 g is no more than 2 hours, since then the user experiences discomfort: neck fatigue, headache, etc. It was found that the added weight of 33 g on average reduced comfortable wearing time by 11 minutes. Headsets with an average weight of 200–300 g can be expected to have an operating time of up to 4 hours, while headsets with a lighter design (approximately 50 g) will have an operating time of up to 6 hours. The operating time depends on the battery capacity, which can be classified into three categories: small (up to 2 hours), medium (approximately 4 hours), and high (up to 6 hours). The specific case depends on the type of production and the operation being performed, but usually the time for monitoring equipment and communicating with a remote expert does not exceed several hours, so high battery capacity is not required. Slipway assembly or repair usually takes an entire work shift (up to 6 hours), the user must often move and does not have the opportunity to use the power supply, as in the case of a stationary workstation. In the authors’ opinion, tasks related to maintenance and training should be classified as an intermediate category. To perform such tasks, a medium-capacity battery is required, providing approximately 4 hours of operation. The architecture of the headset implementation is also related to the case. In situations where the user is required to move outdoors, it is advisable to utilise the standalone version of the headset, which does not require additional blocks or a connection to a mobile device. This is to mitigate the risk of becoming entangled in the wiring. These recommendations should be considered when choosing a headset for outdoor use.

The application case also determines the camera resolution. In cases where very small objects need to be detected or recognized, the resolution must be high137. This is a case of remote expert assistance, monitoring, or quality control, where high-quality image transmission or defect detection is required. It also pertains to assembly scenarios involving the use of artificial intelligence algorithms for recognizing small parts, including hardware. For example, inspection of the assembly of thin bundles in production should be carried out with a camera with the highest resolution, but for inspection of components when assembling the mechanism, the resolution may be lower, because the components are large.

Performance capacity directly contributes to the application case. In assembly, training, and to a lesser extent, repair scenarios, it is often necessary to display virtual three-dimensional models. Additionally, monitoring assembly or execution of operations may require linking the model to a real object. These activities demand high computing capabilities from the headset.

For assembly, high-quality display images and a wide FOV are important. This is because graphic information, drawings, or virtual models with maximum detail and the ability to overlay on real-world objects, which requires an OST device. If the device processes data on a computing unit rather than on a remote server, it requires more computing power to recognize parts, verify assembly, and perform manual operations. The conditions for stationary and slipway assembly differ. In the first case, the user stays at the assembly table or conveyor and can remove the headset or put it on charge. In the second case, the device must be standalone with a long-lasting battery, that is, it must not have cables and external units that could interfere with the user during operation.

Repair and maintenance often require a small headset weight, because they can take a lot of time. At the same time, it is important to distinguish the operating conditions: indoor or outdoor. When using the device outdoors, it is important to protect it from dust, dirt, and moisture, to ensure low weight and acceptable battery life, comfortable wearing during long-term inspection. This is often repair, monitoring, or maintenance, so the user often lacks small visual hints or instructions for operation, which reduces the requirements for display parameters. There is almost no need to overlay information when performing these cases, so assisted reality headsets can be used. For quality control and equipment condition monitoring tasks, it is important to have a high-resolution camera to record video of sensor readings, etc.

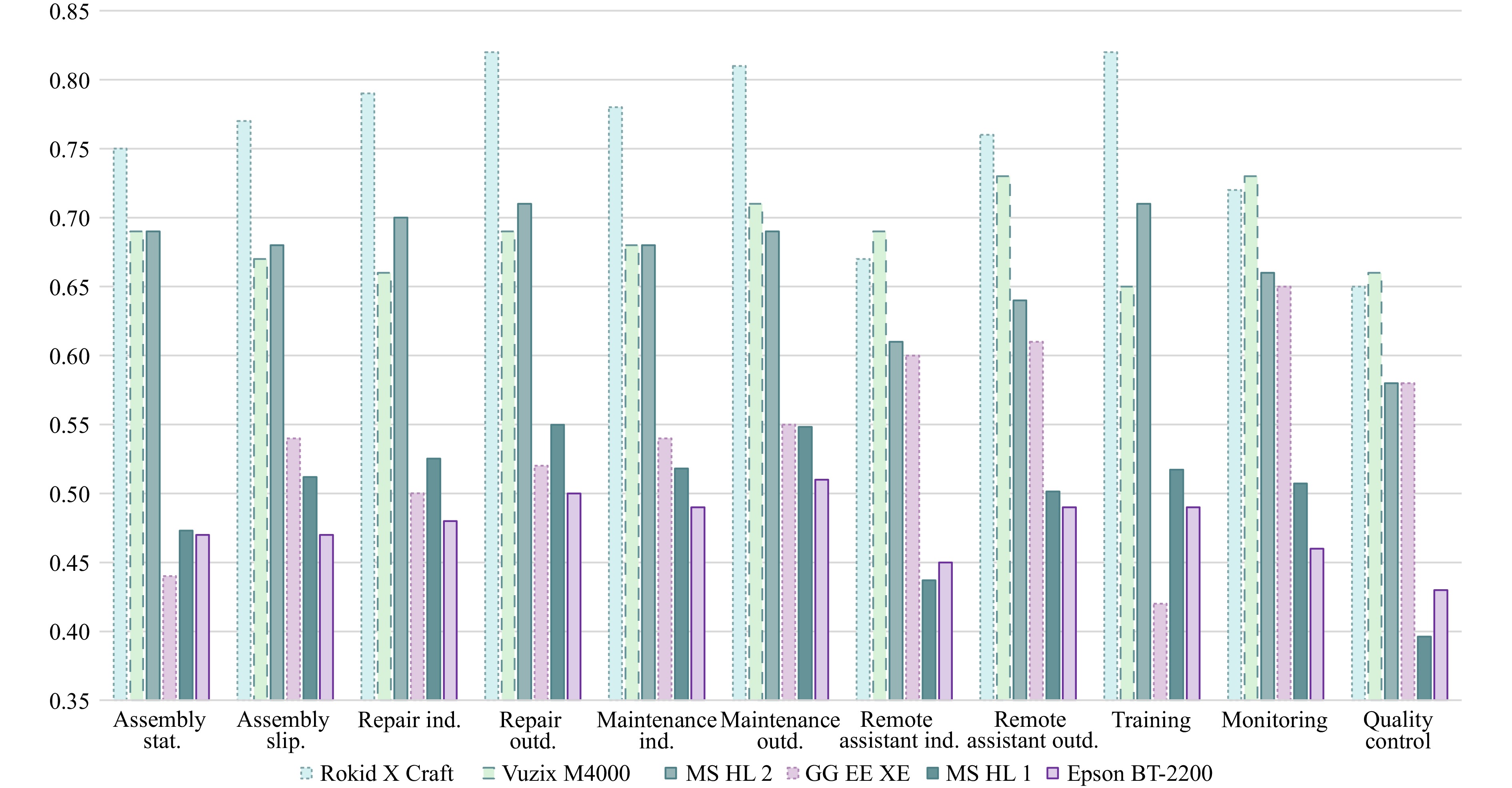

Table 3 presents the criteria for a comparative analysis of headsets in certain application cases based on the evaluation of the devices’ parameters. The comparison will be conducted using an objective metric, with data from Table 2 visualised in the form of diagrams in Fig. 6. The parameter $ S $, which may be considered a general performance indicator, should be estimated for headsets taking into account the specific requirements of a specific application:

$$ \begin{aligned} S=\sum_{m=1}^{n}\text{A}_{m}\cdot k_{m} \end{aligned} $$ (1) Here $ A $ is the normalised parameter value of the headset compared, taken from Table 2 divided by the best value among the headsets being compared; $ m $ defines the parameter number in Table 3; $ n = 9 $ is the maximum number of parameters; $ k $ is a weighting coefficient assigned according to the significance category of the parameter for a specific application case. These coefficients encoded in Table 3 as circles with varying degrees of fill. In this work, the following values are employed: ●: $ k = 0.500 $, ◐: $ k = 0.333 $, ○: $ k = 0.167 $, so that 0.500 + 0.333 + 0.167 = 1. Thus, data from Tables 2 and 3 are used to calculate the general performance of a specific headset $ S $ for a specific case. For example, consider a case of equipment condition monitoring with detection of small objects for defects and malfunctions, carried out outdoors within 1 hour (further referred as “remote assistant defects detection”). The following parameters were designated as $ m = 1, 2, ..., 9 $: 1: display diagonal resolution (px); 2: FOV ($ ^{\circ} $), 3: brightness (nits), 4: camera resolution (Mp), 5: inverse mass — as a measure of lightness (1/g), 6: three parameters at once: RAM (GB), frequency (GHz) and cores as performance capacity, 7: battery life (hours), 8: protection (IP level), 9: standalone function (dimensionless), respectively. Table 3 provides the following $ k_1-k_9 $ values for this case $ k_{1,2,6,7}=0.167 $, and $ k_{3,4,5,8,9}=0.5 $. Let the following headsets be selected for comparison: Vuzix M4000, Rokid X Craft and Epson BT2200. Their parameters were taken from Table 2 and normalised on the best value of each parameter to calculate $ A_m $. This leads to the conclusion that $ A_{\text{M4000}_1} = $ 980[px]/1469[px], $ A_{\text{XCraft}_1} = $ 1469[px]/1469[px] and $ A_{\text{BT2200}_1} = $1101[px]/1469[px] referring to display resolution, $ A_{\text{M4000}_2}=28[^{\circ}]/40[^{\circ}] $, $ A_{\text{XCraft}_2}=40[^{\circ}]/40[^{\circ}] $ and $ A_{\text{BT2200}_2}=23[^{\circ}]/40[^{\circ}] $ referring to FOV, etc. To sum up, the following estimates of the general performance indicator for the compared headsets have been derived:

$$ \begin{split} S_{\text{M4000}} =& 0.167\left( \frac{980}{1469} + \frac{28}{40} + \frac{6}{6} + \frac{2.52}{2.52} + \frac{8}{8} +\frac{2}{8} \right)+\\&0.5 \left( \frac{1000}{1600}+ \frac{12.8}{12.8}+ \frac{222}{222}+ \frac{67}{67} + \frac{1}{1} \right) = 3.084 \\ S_{\text{XCraft}} =& 0.167\left( \frac{1469}{1469} + \frac{40}{40} + \frac{4}{6} + \frac{2.2}{2.52} + \frac{6}{8} + \frac{8}{8} \right)+\\&0.5 \left( \frac{1600}{1600}+ \frac{8}{12.8} + \frac{222}{600}+ \frac{66}{67} + \frac{1}{1} \right) = 2.873 \\ S_{\text{BT2200}} =& 0.167\left( \frac{1101}{1469} + \frac{23}{40} + \frac{1}{6} + \frac{1.2}{2.52} + \frac{2}{8} + \frac{4}{8} \right)+\\&0.5 \left( \frac{1000}{1600}+ \frac{5.1}{12.8}+ \frac{222}{270}+ \frac{54}{66} + \frac{0.5}{1} \right) = 1.720 \end{split} $$ (2) It should be noted that these formulas in Eq. 2 involve solely the parameters of three headsets under comparison. As a result, a process of normalisation is applied to the maximum parameters among the three aforementioned headsets. Accordingly, for remote support defects detection, Vuzix M4000 headset is most suitable among the devices compared in this example. By modelling some specific cases and their input requirements, the most appropriate technical solution can be selected for each task.

Furthermore, Fig. 12 presents general diagrams of the normalised general performance indicator for the camera-enabled headsets in relation to application cases. The maximum value of 1 corresponds to the optimal parameters for the headset, taking into account the specified weighting factors.

It is evident that in most cases the Rokid X Craft headset is in the lead. It can be reasonably deduced that this is due to the fact that it was developed with a specific focus on the industrial sector, and thus initially more adapted to such specific contexts. Nevertheless, even X Craft exhibits a genuine value of the indicator below one, given that each device under study has its drawbacks (weight, low brightness or small FOV). It has been demonstrated that no headset is entirely suitable for any given application case, and thus, headsets are adapted to industrial scenarios in different ways. This finding suggests the potential for further developments and modifications in this field. It should be noted that the numbers presented in the Eq. 2 differ from those shown in the diagrams. This discrepancy provides an additional insight into how the proposed metric S from Eq. 1 varies depending on the number of compared models.

It is acknowledged that the application of specific weightings is open to subjective interpretation. Nevertheless, it is argued that the methodology of direct comparison, described in detail in this work, can be a valuable tool for users, who can set the weighting coefficients themselves and supplement it with additional parameters that may not be present in the devices currently being compared but will be included in future models.

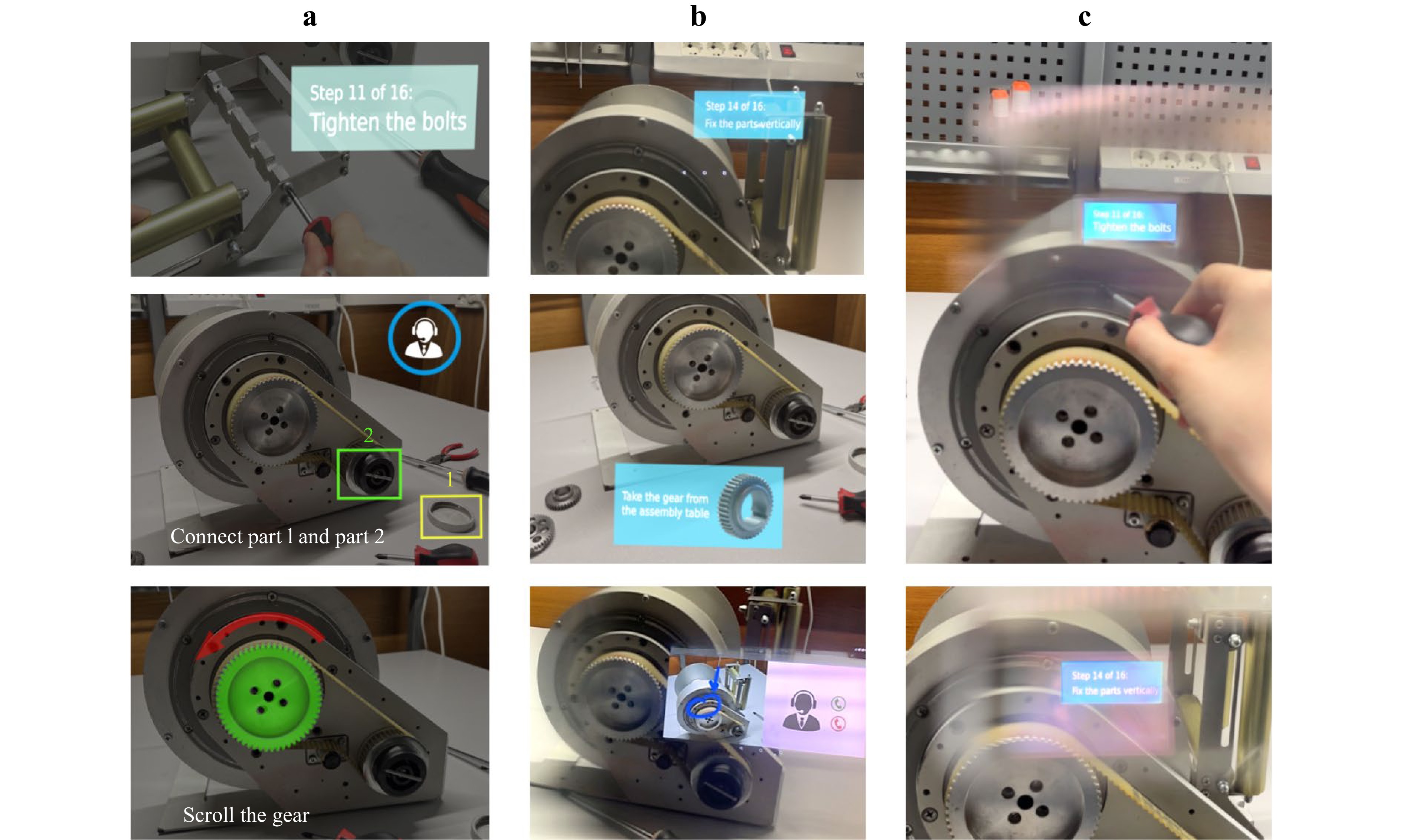

Next, within the framework of experimental studies, the FOV impact on the feasibility of a particular case will be examined. Fig. 13 shows the assembly process using multiple headsets with a different FOV. It should be noted that the output of text instructions during assembly (or repair and maintenance) is a typical case for using AR headsets. When performing operations, the user sees instructions against the background of real objects that he is working with, without being distracted by reading paper documents, and his hands remain free for the tool, as shown in Fig. 13.