-

Utilizing a deep understanding of fundamental optical principles, numerous types of optical devices have been built with distinct functionality. Due to their extensive applications across various sectors, functional optics research has recently emerged as a prominent area of interest among researchers. However, the structural complexity and multi-material distribution of sophisticated optical devices, on the other hand, greatly surpass the fabrication capabilities of existing manufacturing processes, ultimately impeding the continued development of functional optics for various potential applications1. In classical manufacturing, cutting, welding, milling, and grinding methods were particularly prevalent for material removal and machining2. The manufacturing industry is being transformed by additive manufacturing, which has various advantages such as building sophisticated designs, higher material efficiency, dimensional precision, required tolerances, and high surface polish3. AM is the third pillar of manufacturing technology because it complements today’s dominant subtractive and formative manufacturing methods4. Several 3D printing processes are available, such as stereolithography, fused deposition modeling, digital light processing, selective laser sintering, multijet fusion, direct metal laser sintering, electron beam melting, binder jetting, and polyjet5–13. Each additive manufacturing or three-dimensional (3D) printing technology, guided by its fundamental operating principles, commences with a digital component model that is subsequently sliced into layers. In the layer-by-layer approach, consecutive layers of the object are generated through the curing of liquid resins, extrusion of melted polymers and viscous solutions, fine sintering of powders, or lamination of solid layers14. There has been considerable emphasis on utilizing 3D printing to fabricate optical prototypes, aiming to enhance optical properties15–17.

Fresnel lenses (FLs) represent innovative spherical optics known for their optimized mass and material efficiency18–21. Initially employed as collimators for lighthouses, these lenses were specifically designed to withstand the elevated temperatures of the lighthouse environment. In contrast to oil-covered mirrors, glass Fresnel lenses offered the advantages of being lighter and exhibiting lower radiation absorption. This choice of material, driven by considerations of weight and radiation properties, has since been a characteristic feature of Fresnel lenses utilized in lighthouses18–21.

Recognized for their versatile applications, these lenses play a pivotal role in numerous fields. Their utilization spans smartphones, miniature spectrometers, photovoltaic panels, ultrasonic devices, automobiles, and medical equipment. Furthermore, they are integral in various optical functions, serving as condenser optics, field lenses, magnifiers, and collimators. In space applications, silicon Fresnel lenses find utility in solar concentrators with glass protection22–29. Various methods produce Fresnel lenses, including casting, injection molding, and compression molding. However, these techniques heavily depend on mold-based manufacturing processes, constraining design flexibility and processing adaptability30,31. Recently, additively manufactured Fresnel lenses have gained significant attention due to design freedom and process flexibility, resulting in compact, optimized, and functional optical devices. Particularly, VPP-based DLP 3D printing has shown significant advancements in the fabrication of multimaterials and multifunctional Fresnel lenses8,9,15,18. However, further advancements in 3D printing and new functional properties of optical devices are always desirable9,17,32–35.

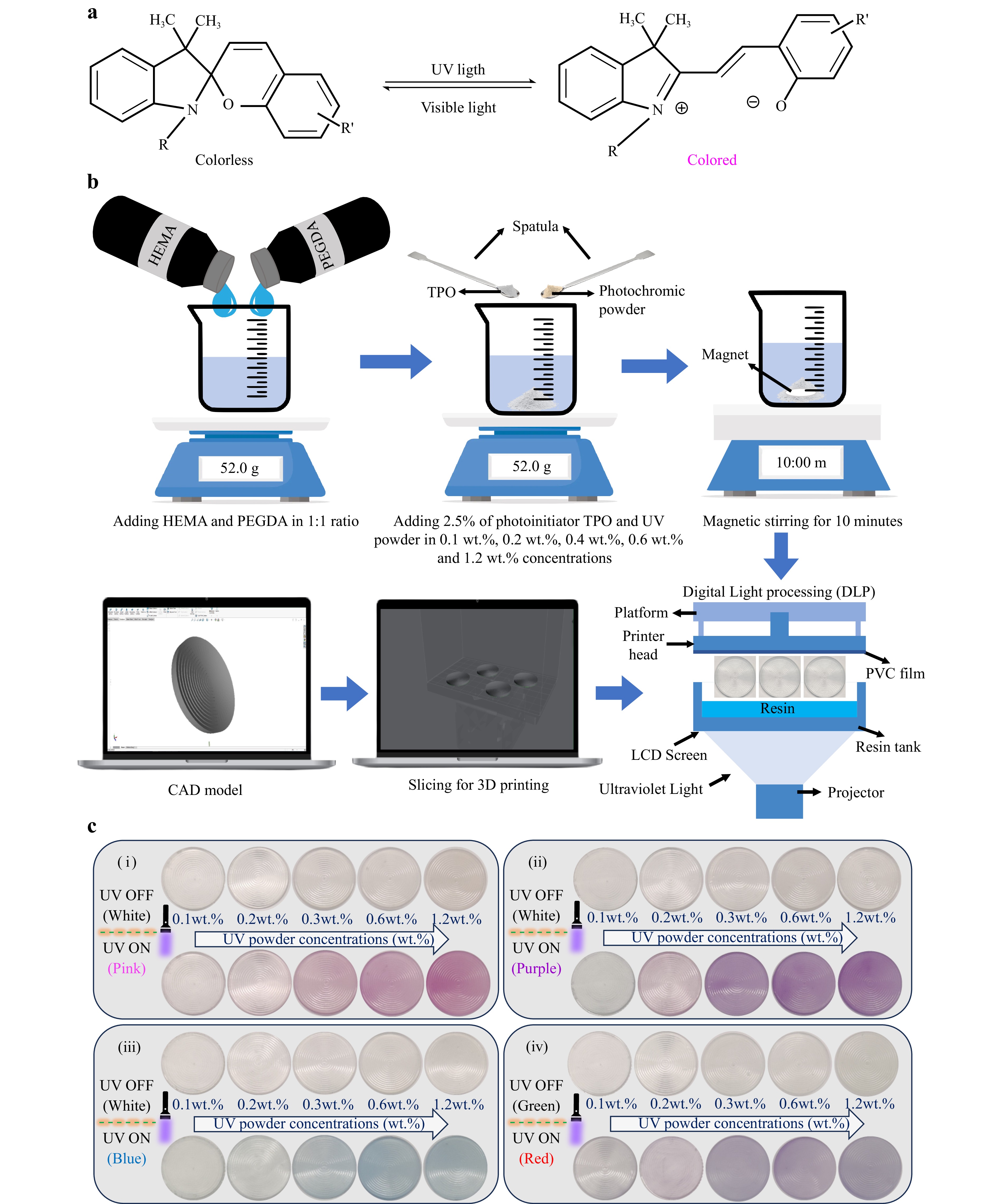

In this work, switchable smart Fresnel lenses enabled with UV responsive photochromic powders are fabricated via DLP-based additive manufacturing. Powders with photochromic properties typically consist of a central photochromic substance such as spirooxazine or spiropyran generally enclosed in a melamine formaldehyde resin, ensuring extended stability for the substance. When subjected to UV radiation, this substance undergoes a reversible isomerization process, resulting in the formation of a merocyanine structure (Fig. 1a)36. Spiropyrans and their derivatives are highly versatile in isomerization under different stimuli under which the C-O spiro bond undergoes cleavage, leading to the creation of the merocyanine form. This reversible transformation involves a charge separation process, causing an elevation in the dipole moment from 4–6 D in spiropyrans to 14–18 D in merocyanine37. The selection of photochromic powders for lens fabrication in the study was based on their rapid color change speed, reversibility, and ability to block UV and blue light, ensuring dynamic optical performance and long-term functionality. The powders also needed to be compatible with vat photopolymerization for uniform dispersion and consistent lens properties while maintaining optical clarity to preserve the quality of the lenses. These criteria were essential to achieve the desired functionality and performance in the 4D printed smart Fresnel lenses.

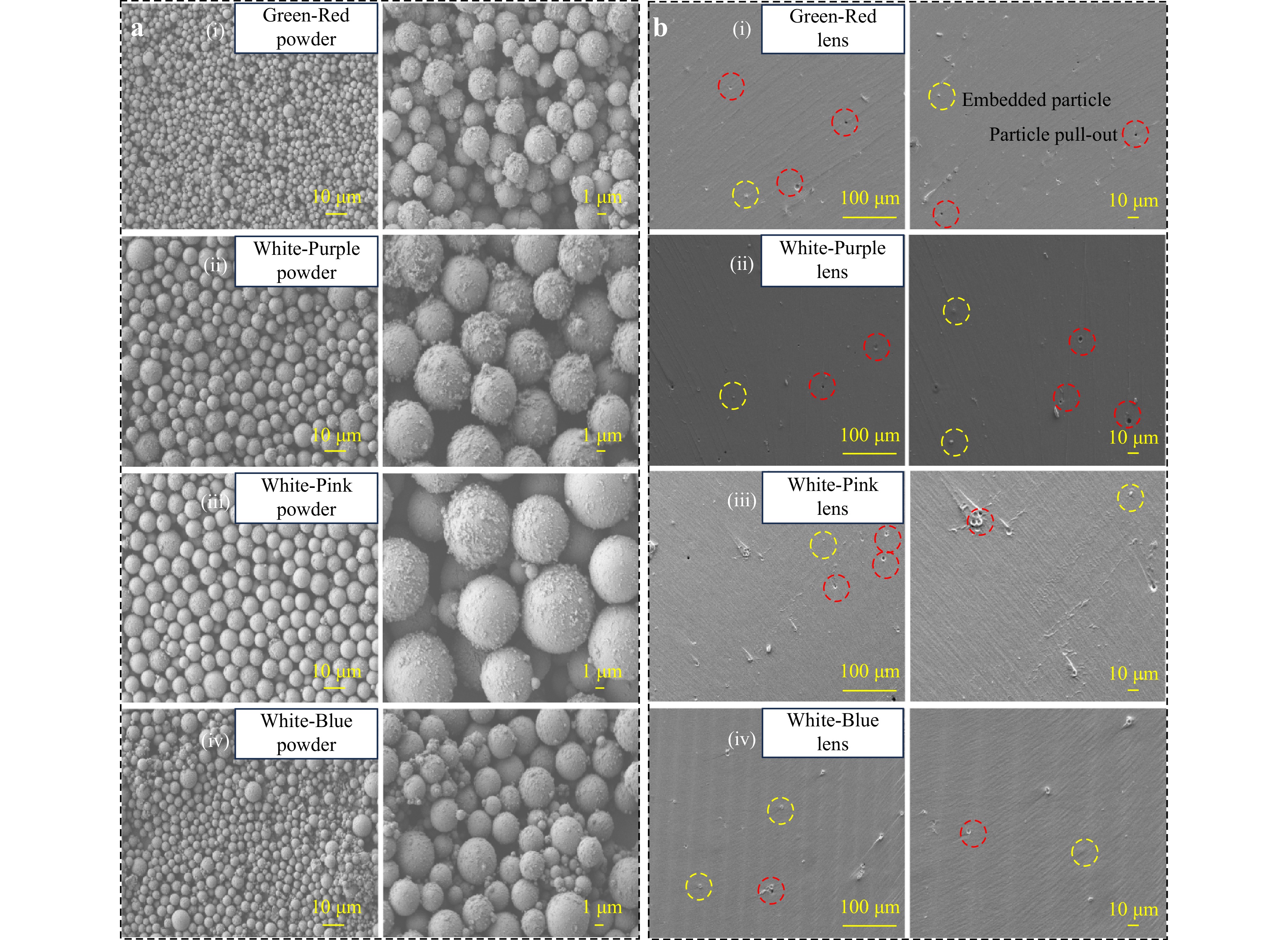

Fig. 1 Morphological investigation of a photochromic powders and b 3D printed UV responsive Fresnel lenses (i) Green-Red, (ii) White-Purple, (iii) White-Pink, and (iv) White-Blue at different magnifications using scanning electron microscopy images. The solid and dotted circles represent particle pull-out and embedded particles, respectively.

In addition to the aforementioned wide range of applications, the fabricated lenses could be utilized for selective coupling applications. Selective coupling is an essential feature in various optical applications where specific light properties must be matched with the requirements of the system. In terms of selective coupling, these Fresnel lenses can be integrated into an optical system where precise control of the above parameters is required. The lenses’ design allows them to focus and direct light efficiently, while their photochromic properties permit dynamic adjustment of light transmission properties. In a practical scenario, a system could be equipped with UV light sources of varying intensities or wavelengths to modulate Fresnel lens characteristics actively38. As a result, the lens can selectively couple light into an optical fiber based on pre-determined conditions or real-time system feedback, ensuring that only the appropriate light characteristics are transmitted through the fiber. This capability is instrumental for advanced optical systems that demand high levels of control and adaptability. These lenses can alter their transmission properties when exposed to UV light, potentially affecting how they interact with other wavelengths of light. This characteristic enables the selective passage of certain wavelengths while blocking others. In an optical fiber system, such a feature can be used to filter out unwanted wavelengths, ensuring that only the desired wavelengths are coupled into the fiber38.

In this study, we utilize vat photopolymerization-based additive manufacturing to fabricate switchable 4D Printed smart Fresnel lenses embedded with photochromic properties. Through DLP 3D printing, we achieved lenses with precise optical performance and geometric accuracy. The integration of photochromic powders allows these lenses to dynamically change color and effectively block UV and blue light upon UV exposure. Comprehensive optical and structural characterization demonstrated the lenses’ high precision, stability, and UV responsiveness, even at low photochromic concentrations. This work underscores the potential of advanced 3D printing technologies in the development of sophisticated optical devices tailored for applications requiring dynamic light modulation and UV filtering, presenting a novel approach that merges cutting-edge manufacturing techniques with functional optical innovation.

-

The morphology of the photochromic microcapsule powders was investigated using SEM images. The samples were prepared and examined under 10 µm and 1 µm magnification as depicted in Fig. 1a(i-iv). Examination through SEM images reveals that the particles exhibit a spherical morphology and possess a core-shell structure. Notably, the pink and purple photochromic powders are of similar size of 4 to 8 µm, while the blue and red powders are 3 to 5 µm. In the examination of the cross-section of the printed lenses via SEM, a method involving the breaking of the lenses in half post-freezing was employed. This technique serves to uphold the integrity of the lenses while mitigating potential structural alterations or damage induced by handling or preparatory procedures. Freezing the samples can help to lock their structure in place. Fig. 1b(i-iv) SEM images depicting the printed lenses, areas showcasing the distribution of photochromic powder, embedded particles, and instances of particle pullouts are shown by dotted circles. The embedded particles observed in the SEM images of the printed lenses denote photochromic powders encapsulated within the lens during the fabrication process. Their presence is significant as they influence the optical properties or mechanical integrity of the lenses. Additionally, particle pullout, as indicated by the dotted lines in the images, refers to instances where these embedded particles are partially or fully extracted from the lens during the sample preparation process. Therefore, the sample preparation method, involving freezing and fracturing, has induced particle pullout in the samples examined in SEM and has no impact on the quality of the lenses. Understanding the distribution and behavior of embedded particles is essential for optimizing the performance and durability of printed lenses. Moreover, it’s noticeable that there are clusters of particle pull-outs evident in the SEM images. However, it’s worth noting that these occurrences seem to be arbitrary and lack any substantial impact on the lenses’ functionality or effectiveness. These clusters may emerge due to localized variations in material attributes or processing conditions during manufacturing. Nonetheless, their presence doesn’t seem to introduce any perceivable adverse effects on the lenses’ optical clarity or structural robustness. Hence, while acknowledging the presence of these clusters, they’re not deemed to pose significant concerns regarding the overall quality or performance of the lenses.

These photochromic pigment powders also showcase distinct switching dynamics in discoloration upon exposure to UV light and the retention of pigment powders afterward. The variations are evident in the time required for both the pigment switch and reversion. The disparities in the switching behavior of the different types of lenses primarily stem from the chemical structure of the spiropyran dye and the solvent used. In a broader context, molecules with photoactive properties, such as spiropyrans, display unique absorption wavelengths39. Therefore, the key factor influencing variations in discoloration times and intensity is either the solvent employed or the chemical structure of the spiropyran37. Likewise, the spiropyran utilized in all the powders may possess distinct chemical structures. The core photochromic compound is typically enclosed within a melamine-formaldehyde resin matrix. This encapsulation significantly enhances the powder’s long-term stability39.

Two prevalent spiropyran dyes in literature are 5SP (indolinospironaphthopyran) and 6SP (indolinospirobenzopyran with a 6-nitro substitution). The primary structural divergence lies in the substitution of the fused benzo ring in 5SP with a 6-nitro group, resulting in 6SP. Literature suggests that 5SP dyes exhibit significantly faster reverse photochromism rates compared to 6SP dyes, leading to more pronounced photochromic intensities for the latter. The nitro substitution enhances the photochromism of 6SP dyes, making them at least an order of magnitude more intense than other derivatives. Another distinction pertains to their solvatochromism, wherein the introduction of the nitro group enhances the zwitterionic form of the merocyanine species, influencing the dyes’ solvatochromism from positive to negative. This shift causes alterations in polarity and maximal absorbance trends. For highly polar solvents, 5SP dyes exhibit maximum absorption at about 560–610 nm, while 6SP dyes have their peak absorption at 530–560 nm. Based on the photochromic optical properties of our lenses, the blue, purple, pink and red powders employed herein can be identified as 5SP and 6SP dyes, respectively. The discernible variations in response time and absorption intensity between the four transition Fresnel lenses provide room for user-specific customization40.

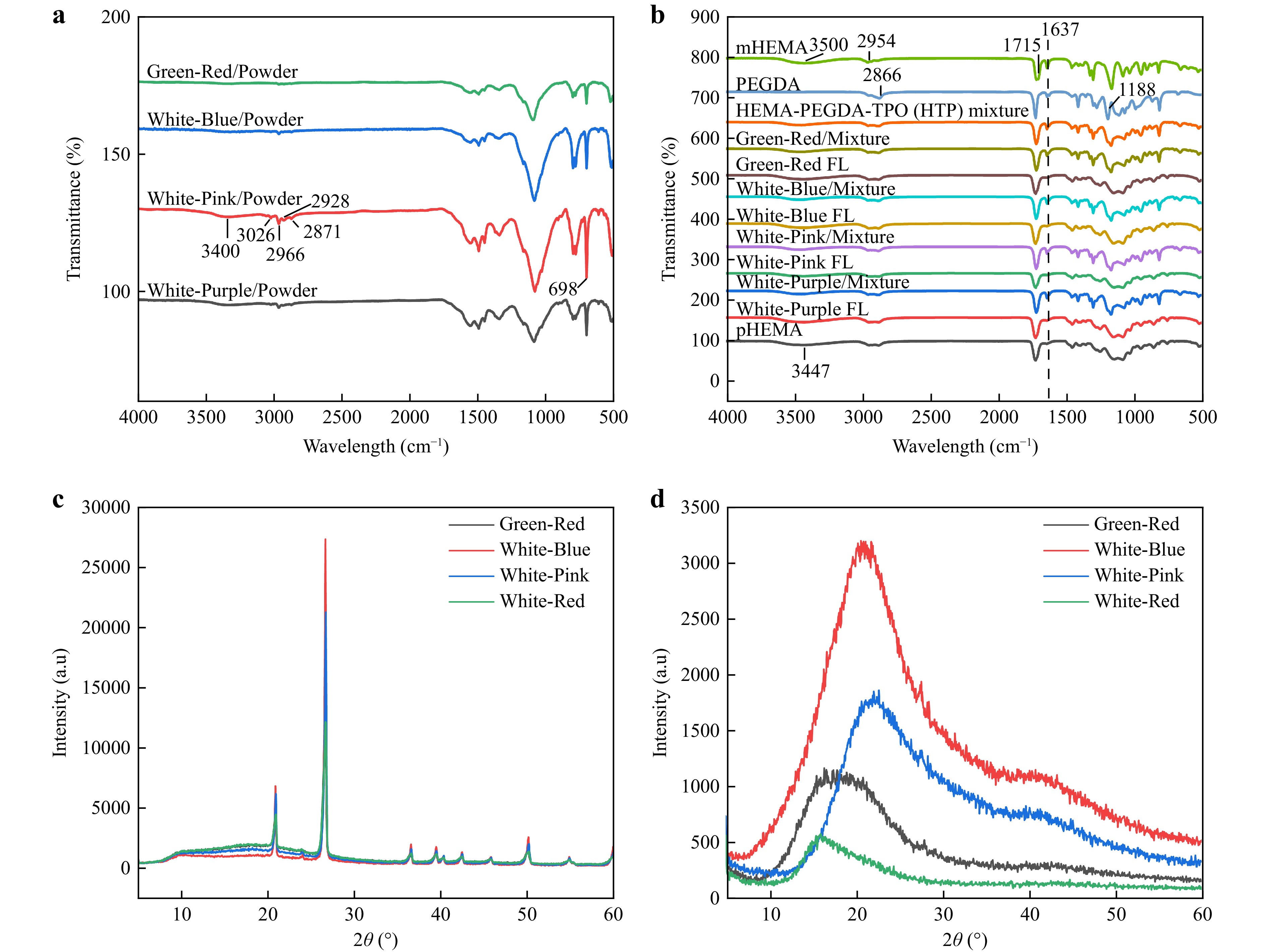

The FTIR spectra depicted in Fig. 2a unveil characteristic peaks associated with four distinct powders: Green-Red, White-Blue, White-Pink, and White-Purple, with a concentration of 1.2 wt.% in the HEMA polymer matrix. The four photochromic powders exhibit similar peaks. The presence of a peak at 2966 cm−1 is attributed to the asymmetric stretching vibrations of the –CH2OH group41. Similarly, the peaks observed at 2928 cm−1 and 2871 cm−1 are indicative of the asymmetric and symmetric stretching vibrations of the –CH2 group, respectively42. Furthermore, the stretching vibration peaks at 3400 cm−1 are associated with the N-H and O-H bonds, common in diverse organic compounds (Fig. 2a)42. The FTIR spectra in Fig. 2b show the characteristic peaks for the resin components (monomer HEMA (mHEMA), PEGDA, and TPO), resin/UV powders mixture solutions, and their respective 3D printed lenses. In Fig. 2b, for the HEMA spectrum, there are –OH bond at 3500 cm−1, CH2 at 2866 cm−1, C=O at 1715 cm−1, and C=C at 1637 cm−1. Conversely, the PEGDA spectrum shows peaks corresponding to CH2 at 2866 cm−1 and C=C at 1637 cm−1 9,43. It’s evident that no new peaks were observed upon mixing four different types of UV powders with resin solution. Moreover, the C=C peak at 1637 cm−1 disappeared from the polymerized 3D printed lenses upon curing, highlighting the successful photopolymerization of the resin material.

Fig. 2 FTIR spectroscopic analysis of a four different UV responsive photochromic powders and b resin materials including monomer, crosslinker, and photoinitiator and their mixtures before and after 3D printing. XRD patterns analysis: c photochromic powders and d 3D printed Fresnel lenses with 1.2 wt.% of four photochromic powders including Green-Red, White-Blue, White-Pink, and White-Red.

To ascertain the crystallinity of both photochromic powders and printed Fresnel lenses, X-ray diffraction characterization was conducted. In Fig. 2c, the four photochromic powders reveal prominent peaks at 2θ angles of 21.0°, 27.0°, and 50°. These distinct sharp peaks serve as confirmation of the crystalline nature of the photochromic powder44. The broad XRD peaks in Fig. 2d primarily reflect the amorphous nature of the polymer matrix. The low concentration (1.2 wt.%) of photochromic powder within the polymer matrix, combined with its distribution in the amorphous polymer, causes the crystalline peaks to be obscured within the broader amorphous peak. The spectra of all lenses exhibit a consistent feature: broad peaks at a 2θ range of 15−25°. The presence of these singular broad peaks, devoid of any sharp peaks, indicates the overall amorphous nature of the lens material45.

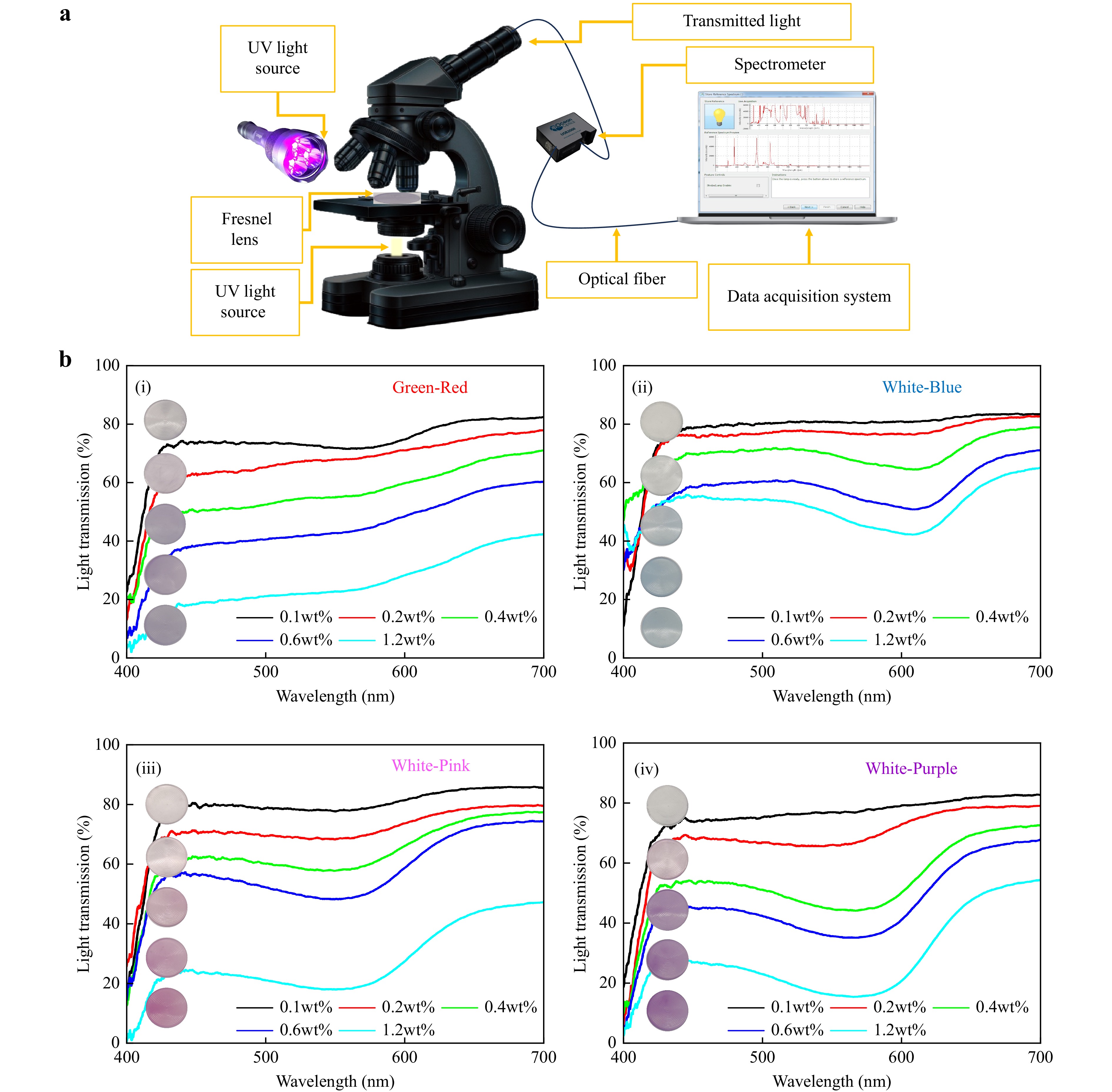

Upon exposure to UV light, Fresnel lenses undergo darkening, regulating the amount of transmitted light. The quantification of this darkening, indicative of the lens’s response to UV, involves exposing them to UV light and recording the corresponding transmission spectra at their activated states. The experimental setup utilized for assessing the lenses’ UV responsiveness featured a white light source integrated with an optical microscope connected to a UV–Vis spectrometer. Activation of the transition lenses was achieved using a UV torch with a wavelength of 375 nm, and saturation of the photochromic powders within the lenses was ensured through 45 seconds of UV illumination. Notably, the UV responsiveness of the sets of Fresnel lenses primarily relied on the concentration of the incorporated powders. Upon UV exposure, the lenses darkened, leading to a decrease in transmission. The extent of light absorption in response to UV varied between approximately 5–70% for the utilized concentrations of 0.1wt%–1.2wt%, respectively.

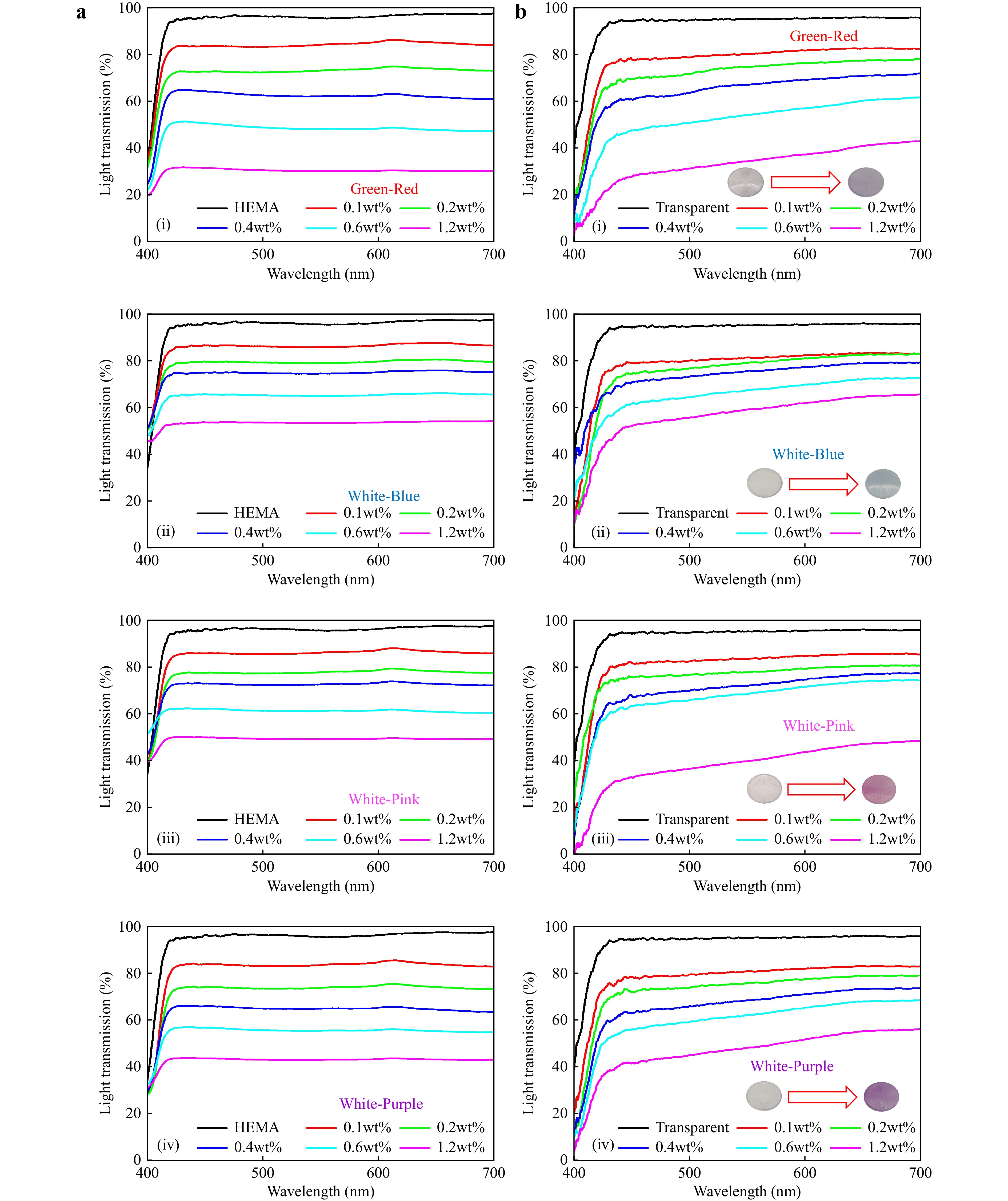

The transmission spectra of both the resin and the printed lenses in their inactivated states are depicted in Fig. 3a, b. Before polymerization, four distinct concentrations of each UV powder (White-Blue, White-Pink, White-Purple, and Green-Red) were incorporated into the resin. The overall average transmission of the resin, incorporating various concentrations of the photochromic powders, ranges from 85% to 35%, as shown in Fig. 3a(i-iv). While there are slight variations in the transmission of resin with different photochromic powders, this is consistent with the transmission spectra of the printed lenses. Notably, the transmission spectra of the printed lenses indicate that the green-red lens blocks the most light, while the White-Blue lens blocks the least. Despite clear differences in the transmission among different sets of lenses, the transmission spectra of lenses with a 0.1 wt.% concentration are very similar, ranging between 70% and 80%. However, this difference increases significantly with the concentration of the photochromic powders.

Fig. 3 Optical transmission spectra of a liquid resin and b printed lenses of (i) Green-Red, (ii) White-Blue, (iii) White-Pink and (iv) White-Purple photochromic powders at their inactive state.

Thus, the micro-sized particles potentially scatter light and negatively impact the optical performance of the lens. We conducted experiments using various concentrations of photochromic powders ranging from 0.1 to 1.2 wt.%. As illustrated in Fig. 3a(i-iv), when the concentration of micro-powders was increased from 0.1 to 1.2 wt.%, we observed a gradual decrease in light transmission. This decrease is attributed to potential light scattering and absorption by the incorporated powder within the polymer matrix. We observed and quantified a noticeable UV responsiveness within this specific concentration range (0.1−1.2 wt.%) using spectroscopic and calorimetric analyses. However, concentrations below 0.1 wt.% resulted in minimal UV responsiveness, while concentrations above 1.2 wt.% significantly reduced optical transmission, making the lenses less effective for practical applications. Therefore, an appropriate concentration within the mentioned range can be selected based on specific application requirements to achieve the desired response. Our findings demonstrate that a measurable optical performance (UV responsiveness and focusing capabilities) without adverse effects was achieved within this concentration range of 0.1 to 0.2 wt.% of photochromic powders. This indicates that the scattering of light by these micro-sized particles did not significantly impair the overall optical performance of the lenses. In Fig. 3b(i-iv), upon comparison of the transmission spectra between the resin and the printed lenses, it becomes evident that the printed lenses exhibit a slightly lower transmission than their respective resin counterparts prior to polymerization, as anticipated. However, a distinct contrast is observed in the transmission spectra of the printed lenses devoid of any photochromic powder compared to those incorporating the said powder. Despite the minimal presence of the powders, the lenses demonstrated effective filtering properties in comparison to untreated transparent lenses. The absence of visible absorption from the photochromic pigment in the transmission spectra is because the pigment was inactive (unexposed) during the measurements (Fig. 3a, b). Photochromic pigments typically exhibit visible light absorption only when exposed to UV light, which causes them to undergo a reversible chemical change, leading to the absorption of visible light.In this work, the transmission spectra were recorded under conditions where UV light had not activated the photochromic pigment, which explains the lack of visible light absorption. When activated, the pigment would indeed show a significant change in the absorption characteristics, corresponding to its photochromic behavior. Thus, all sets of lenses exhibited commendable light absorption, and it is noteworthy that the photochromic powders displayed superior filtering capabilities, resulting in enhanced transmission with a decrease in powder concentrations.

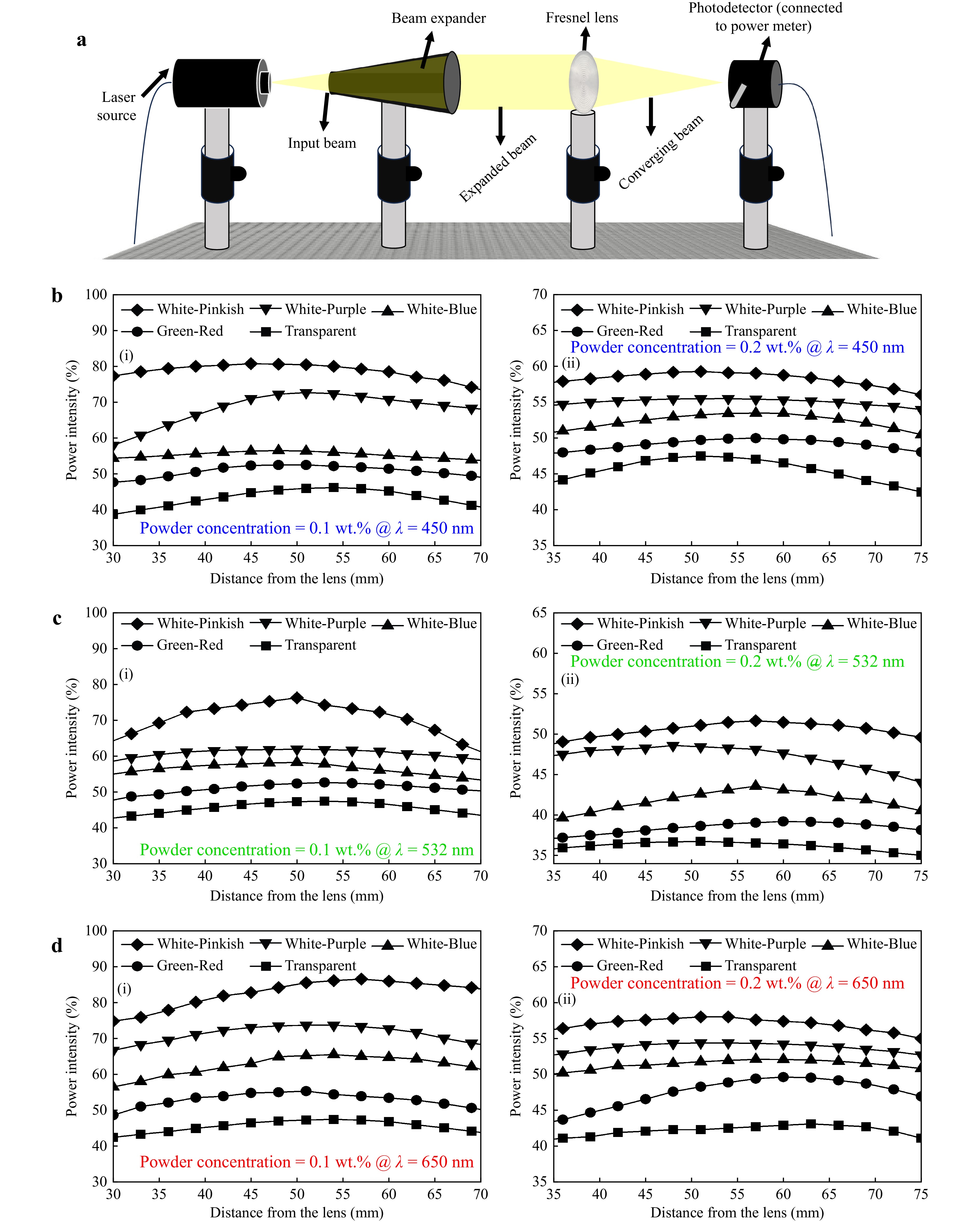

A customized setup was utilized to measure the focal distances of colored 3D printed Fresnel lenses. After cleaning and drying, the lenses were placed on glass slides for better handling and to prevent any harm during the experiments. The setup to measure the focal length included lasers of different colors (blue, green, and red), a beam expander (a device to make the laser beams wider and straight), the Fresnel lenses on glass slides, and an optical power meter (a device to measure light intensity). These parts were put together on a movable stage with special mounts to keep them in place. The lasers shone through the beam expander, which made sure the lens was entirely illuminated. The light that went through the lens was brought into focus at certain points. The optical power meter was moved to find where the light intensity was highest for each colored laser. This point of highest light intensity was noted as the focal length for each lens. The recorded intensity of the light was compared and adjusted to the highest intensity of the laser measured before it entered the beam expander. The schematic illustration of the experimental setup is depicted in Fig. 4a. Concentrating on accuracy, focal length measurements were carried out for all three laser beam light sources across four distinct Fresnel lenses: Green-Red, White-Blue, White-Purple, and White-Pink, as depicted in Fig. 4b-d. Initially, each of these lenses underwent illumination with a beam of blue laser light, aiding the evaluation of relative power intensity. This evaluation involved shifting the power meter mount along the focal axis of the Fresnel lens, allowing the observation of a noticeable intensity at the focal points. Particularly, lower optical intensities were noted before and after the focal length range, highlighting the lens’s focusing efficiency. This characterization process was uniformly done for all lenses by moving the power meter on the optical breadboard using a rail mount. Every 3 mm, power intensity readings were recorded, revealing a consistent pattern: initially, lower power intensity readings gradually rose while approaching the focal length. At the focal point, the highest power intensity was achieved, followed by a gradual decrease as the power meter moved away from the lens’s focal point. All printed lenses fall within the focal length range of 40 mm to 60 mm, closely approximating the intended design focal length of 50 mm. It is crucial to emphasize that, with an increase in the concentration of photochromic powders, there was a corresponding escalation in the variation of focal length among the printed lenses. Lenses with concentrations of 0.1 wt% and 0.2 wt% exhibited acceptable errors, aligning closely with the design values. However, concentrations exceeding 0.2 wt% displayed variations exceeding 10 mm from the intended focal length. The increasing error stems directly from the higher concentration of the integrated photochromic powder. This elevated concentration within the resin disrupts the layer-by-layer printing process, thus influencing the overall print quality. The focal size of the Fresnel lenses does not significantly change with varying concentrations of the photochromic pigments in the range of 0.1 to 0.2 wt.%. As described in the manuscript, the primary function of the photochromic pigments is to alter the optical density of the lens in response to UV light, without affecting the lens’s geometrical properties. However, during our experiments, at higher concentrations of the photochromic pigments, the focal size remained inconsistent, indicating that the optical performance of the lens, in terms of focus, is not preserved. This stability is crucial for ensuring that the lenses can function effectively across various lighting conditions without compromising their optical precision. Thus, at higher concentrations (above 0.2 wt.%), various possible factors, including a layer-by-layer 3D printing process, refractive index variation with concentration46, wavelength, and temperature along with the surface roughness, and misalignment of the customized optical setup may have influenced the optical performance of the lenses47,48.

Fig. 4 a Illustrates schematic diagram of the experimental setup for focal length measurements. Focal length measuring using three different laser beam sources b Blue, c Green, and d Red Lasers of 450, 532, and 650 nm, respectively. Focal length measurement of Transparent FL, White-Pink FL, White-Purple FL, White-Blue FL, and Green-Red FL (i) 0.1 wt.% and (ii) 0.2 wt.% respectively.

The transmission spectra of the printed lenses were also recorded in their active state. This was done by shining UV light of 375nm at the lenses as shown in Fig. 5a. In the active states due to distinct emitted colors, the visible light filtered wavelengths for each set of Fresnel lenses also differed. Blue photochromic lenses predominantly filtered wavelengths in the range of 550–650 nm. In contrast, pink lenses exhibit the highest light absorption between 500–600 nm, while purple lenses manifest increased absorption spanning in the range of 500–650 nm. For green to red lenses, the dominant absorption takes place within the range of 450–650 nm. It’s worth mentioning that the transparency of the Fresnel lenses was not significantly affected by the photochromic activation during UV exposure. While the lenses underwent darkening, acquired color, and blocked a specific wavelength range, the overall transparency remained largely unaffected, as depicted in the digital images in Fig. 5b. Analyzing the transmission of the four sets of Fresnel lenses in Fig. 5b(i-iv), it’s observed that the UV responsiveness of the lenses doesn’t notably increase with higher concentrations of the photochromic powder. However, at elevated concentrations, there’s a considerable reduction in transmission.

Fig. 5 a Schematic of the experimental setup for measuring the UV responsiveness of the Fresnel lenses. b Optical transmission spectra of printed lenses of (i) Green-Red, (ii) White-Blue, (iii) White-Pink and (iv) White-Purple photochromic powders at their active state due to UV exposure.

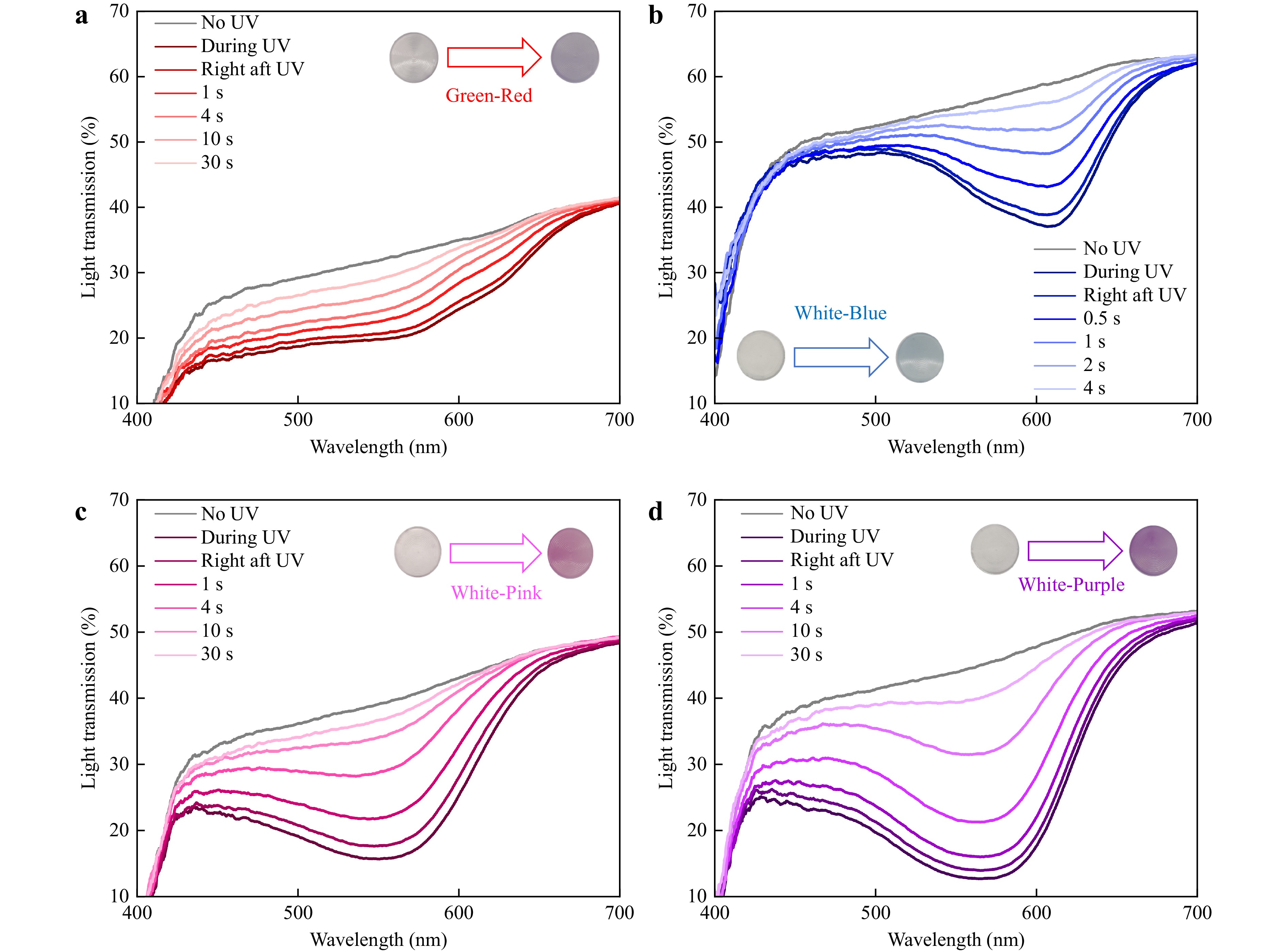

The response of Fresnel lenses to UV-induced coloration was rapid, yet the rates of discoloration varied between the two sets. It is worth noting that the time required for complete discoloration and reversal not only relied on the type of photochromic powder but also slightly on the concentrations employed. Fig. 6 shows the time-dependent transmission spectra of the printed sets of lenses, which start with higher transmission in the absence of UV light and undergo a significant decrease in various regions of the visible spectrum during UV exposure, indicating a robust photochromic response. It can be clearly seen in Fig. 4 that the lenses with photochromic powder filter blue light even in their inactive states, which is also evident from Fig. 6. Upon UV exposure, lenses with different photochromic powders behave differently. The Green-Red lens filters the least upon exposure to UV light with reference to their inactive, while the White-Purple lens exhibits the most filtering capability. However, it is also important to note that lenses with pigment concentrations below 0.2 wt.%, such as 0.1wt.% exhibit a significant color change upon UV exposure, the intended functional response. Thus, we have optimized these specific UV-responsive powder concentrations in the 0.1 to 0.2 wt.% range, providing measurable focusing and color change responses—the color difference as measured by the transmission spectra difference (without UV- with UV) for the respective lenses incorporated with 0.1wt.% and 0.2wt.% pigment powders are provided in Figure SI 2. The variations in transmitted spectra of 1 to 11% were observed for the lenses in the 0.1 to 0.2wt.% concentration range after exposure to UV light representing significant color variations.

Fig. 6 Time-dependent transmission spectra of printed lenses of a Green-Red, b White-Blue, c White-Pink, and d White-Purple photochromic powders Without UV exposure, during UV exposure and at different times after UV exposure.

In Fig. 6b, White-Blue transition lenses exhibited a quick response, achieving 95% discoloration within a mere 4 seconds. Conversely, White-Pink, White-Purple, and Green-Red transition lenses displayed a notably slower and similar response, taking up to 30 seconds to achieve 95% discoloration as presented in Fig. 6a, c and d. The White-Blue lens is also the one that filters the least amount of blue light in the active state with reference to the inactive state. This difference in their response time, transmission, and filtering region makes these types of lenses highly customizable. The effectiveness of each lens at blocking light during UV exposure and the recovery time post-exposure are critical parameters for designing applications that require precise control over light transmission. These lenses underwent multiple illuminations for time-dependent transmission spectra and irradiation durability over 50 cycles, with a minimum one-minute gap between each cycle, there was no notable difference in the transmission spectra showing the durability of the lenses.

Several strategies can be employed to enhance the stability and durability of 4D printed smart Fresnel lenses. First, optimizing the concentration and ensuring uniform dispersion of photochromic powders within the resin can significantly improve the lenses’ responsiveness and long-term stability while minimizing focal length errors to maintain consistent optical performance. Second, improving the resin formulation by developing UV-stable resins and incorporating stabilizers like UV inhibitors or antioxidants can prevent material degradation and color changes, thereby enhancing the structural integrity and longevity of the lenses when expose to prolonged UV light. Third, applying enhanced protective coatings, such as anti-UV and scratch-resistant layers, can shield the lenses from UV-induced damage and physical wear, preserving their optical clarity and extending their operational lifespan. Additionally, refining manufacturing techniques by implementing layer-by-layer reinforcement during vat photopolymerization and applying post-processing treatments like annealing can increase the mechanical strength and stability of the lenses, reducing the risk of deformation or breakage. Moreover, conducting thorough environmental testing, including accelerated aging and cycle testing, can help identify potential lens weaknesses, allowing for iterative design improvements that ensure durability under real-world conditions. Lastly, increasing the crosslinking density of the polymer resin by incorporating crosslinking agents can enhance the network density, improving the mechanical properties and resistance to environmental stress, thereby reducing material fatigue and further extending the durability of the lenses. By combining these strategies, the 4D printed smart Fresnel lenses can be more robust, ensuring that they maintain their high-performance optical properties and structural integrity over extended periods and under various challenging conditions.

-

The study successfully fabricated switchable 4D printed Fresnel lenses using a vat photopolymerization-based DLP 3D printing process, employing self-prepared resin mixed with photochromic powder. These materials were selected for their optimal physical and optical properties, enabling the fabrication of lenses that not only handle well during and after printing but also exhibit significant optical performance. The incorporation of photochromic powders at concentrations of 0.1 wt.% and 0.2 wt.% resulted in lenses that transmit 70%−85% of light, showcasing their efficiency. Although lenses with higher concentrations of photochromic powders demonstrated reduced light transmission, their responsiveness to UV light was notably superior. Among the various sets tested, lenses containing White-Blue photochromic powders outperformed others in terms of light transmission. Upon UV exposure, all lens sets transition to a colored state within 5−10 seconds. Lenses incorporating blue photochromic powder reverted to 95% of their colorless state in merely 4 seconds, contrasting with the 30-second timeframe for other lenses to achieve similar clarity. This behavior was consistent across each set, indicating that the photochromic concentration has minimal impact on this response time. Focal length analysis conducted with custom optical setups revealed that the measurements for lenses with 0.1 wt.% and 0.2 wt.% photochromic concentrations closely align with the designed focal lengths, highlighting their precision. However, further investigation is necessary to refine these measurements for even greater accuracy. Enhancements in light transmission and focusing capabilities are achievable by reducing the printing layer thickness to below 35 μm. This adjustment minimizes the stair-stepping effect commonly observed in 3D printed objects, thereby improving the lenses’ optical clarity. The durability of these lenses was confirmed through tests, which showed that they maintain transparency and UV responsiveness after 50 UV light activation cycles.

Thus, the implementation of vat photopolymerization in our study enhances the manufacturing of 4D printed smart Fresnel lenses by offering greater design flexibility, allowing for more intricate and precise lens geometries without the limitations of mold-based methods. It also improves dimensional accuracy and minimizes focal length errors, which are crucial for optimal optical performance. Additionally, vat photopolymerization enables the integration of dynamic photochromic properties, allowing the lenses to change color and filter UV and blue light upon exposure—capabilities that are challenging to achieve with traditional techniques. This method also ensures stability and repeatability, with lenses maintaining their properties over multiple UV exposure cycles, ensuring the functional and durability advantages of VPP-based 3D printing processes. Future work could explore surface smoothness improvements via dip coating in post-printing processes and delve into optimizing mechanical properties. The variation observed across the four lens sets indicates the potential for tailoring these multifunctional lenses to meet specific user requirements, particularly in filtering UV and blue light. This customization capability, combined with the discussed enhancements, underscores the lenses’ innovative design and functional versatility.

-

The resin formulation comprised 2-hydroxyethyl methacrylate (HEMA), polyethylene glycol diacrylate (PEGDA), and trimethylbenzoyl diphenylphosphine oxide (TPO) as the monomer, cross-linker, and photoinitiator, respectively. A 1:1 ratio of monomer to cross-linker was mixed, and 2.5% of the photoinitiator was added to the resulting resin solution. Additionally, photochromic powders from Hangzhou Tiankai in Zhejiang, China were introduced into the resin material to modify its optical properties. As mentioned previously, photochromic powders usually contain a central substance like spirooxazine or spiropyran, encased in melamine formaldehyde resin for stability. Under UV radiation, this substance reversibly changes to a merocyanine structure (Fig. 7a). Transparent polyvinyl chloride (PVC) smooth plastic film served as a support on the print bed during 3D printing to achieve a high-quality surface. Throughout the printing process, cleaning and drying were carried out using isopropyl alcohol (IPA), deionized (DI) water, and ethanol.

Fig. 7 Fabrication of switchable smart Fresnel lenses. a Chemical structure of photochromic spiropyran structured material (colorless) switching to merocyanine (colored). b Schematic of the lenses’ fabrication process including CAD modeling, slicing, and 3D printing. c Switchable Fresnel lenses, featuring various photochromic powders at different concentrations, in both their active and inactive states (i) White-Pink (Pink), (ii) White-Purple (Purple), (iii) White-Blue (Blue) and (iv) Green-Red (Red).

-

The Fresnel lens design configuration is based on constant height, and the schematic illustration is provided in supporting information in Figure SI 1. The design of the Fresnel lens encompasses the precise calculation of its focal length, the specific number of concentric rings, and the precise bending angle of each ring that constitutes a groove. A Fresnel lens was thus crafted with a diameter of 25 mm, incorporating 15 concentric rings, each with a uniform width of 0.833 mm, culminating in a lens with a thickness of 2 mm. This configuration was intended to yield a lens with a focal length of 50 mm. The height of each ring was engineered to increase progressively from the center towards the outer edge, reaching a peak height of approximately 0.4 mm at the outermost ring. This lens was digitally drafted using SolidWorks and was subsequently converted into a standard triangulation language (STL) file format. For the final stage of preparation, the STL file was sectioned into layers ready for 3D printing with the use of Slicer software.

-

The fabrication process of the lens, starting with the resin preparation, followed by the design of the Fresnel lens, slicing, and culminating in the printing process, alongside a schematic representation of the printer setup is provided in Fig. 7b. The design file, after being sliced using the Wanhao slicing software was fed to The Wanhao Duplicator 7 3D printer. Support from slicing software is vital for 3D printing, but it can introduce undesirable roughness on the lens model due to impressions from the support structures. To bypass the need for support and enhance surface smoothness after printing, commercially available PVC film is utilized. Before the printing process begins, crucial parameters such as layer thickness, cure time, and layer speed are carefully chosen for optimal outcomes (Table 1). Once printing is finished, the samples are gently separated from the PVC film to avoid any scratches or damage. The samples are then immersed in an isopropyl solution to clean away any uncured resin. After this cleaning step, the samples are left to air-dry at room temperature and then placed in an oven for 5 minutes. The four sets of printed lenses (i) White-Pink, (ii) White-Purple, (iii) White-Blue, and (iv) Green-Red) in their active and inactive states are shown in Fig. 7c(i-iv).

DLP printing parameters Specifications Layer thickness 35 µm Curing time Burn layers (80 s), Normal layers (45 s) Normal layer speed Lifting speed 40 mm/min, lowering speed 40 mm/min Slow selected layer speed Lifting speed 50 mm/min, lowering speed 50 mm/min Wait after lift 1 s Lift after print 5 mm Support No support- thick PVC film Table 1. Printing parameters.

The printing parameters for the DLP 3D printer are meticulously optimized to ensure the production of high-quality Fresnel lenses. The layer thickness is set to 35 µm, balancing fine detail with efficient build times. The curing time is differentiated between burn layers, requiring 80 seconds to form a robust foundation, and normal layers, curing in 45 seconds for rapid layer building. Normal layer speed involves lifting and lowering speed of 40 mm/min, ensuring steady layer separation and adhesion. For selected layers needing more precision, the lifting speed is increased to 50 mm/min while maintaining the same lowering speed, optimizing the curing process. A brief wait time of 1 second after each lift minimizes the risk of defects. After printing, a 5 mm lift ensures safe removal from the build platform. The use of a thick plastic film for support negates the need for additional structures, ensuring a smooth finish. These parameters collectively contribute to the precision and quality of the 3D printed Fresnel lenses.

-

The characterization of the Fresnel lenses covered assessments of their optical, physicochemical, and morphological features. Initially, the photochromic powders were characterized. Fourier Transform Infrared Spectroscopy (FTIR) was used to analyze the chemical interactions of resin components along with the powder’s integration. Furthermore, the morphology of the microcapsule powders was examined using Scanning Electron Microscopy (SEM, FEI Nova NanoSEM 650). For the SEM analysis, the powders were dissolved in a 10 wt.% DMSO solution, and then several droplets were placed on carbon tape and allowed to dry at room temperature. To prepare the printed samples for SEM analysis, the Fresnel lenses were frozen and then fractured. A torch light from uvBeast was employed to subject the lenses to UV light, allowing for the examination of their photochromic response. The optical properties of these lenses were meticulously evaluated using a customized optical setup. Measurements of the optical transmission spectra were conducted with an optical microscope (AXIO, Scope A1, Germany), ensuring a comprehensive assessment of the lenses’ performance across various dimensions.

-

The UV responsiveness of the 4D printed smart Fresnel lenses was tested under controlled conditions, including specific UV light sources (375 nm, 1600 lumens), exposure times (0−30s), and environmental settings (room temperature), to simulate real-world usage. The responsiveness was evaluated using colorimetric analysis and spectrophotometry to measure color change and UV/blue light blocking capabilities. Reversibility testing was also conducted to assess how well the lenses could repeatedly return to their original color after UV exposure. These methods and conditions ensured a comprehensive evaluation of the UV responsiveness of the smart Fresnel lenses, confirming their suitability for applications requiring dynamic light modulation and UV protection.

-

We acknowledge Khalifa University for the research funding, in the form of Advanced Digital & Additive Manufacturing (ADAM) Group (Award No. RCII-2019-003), in support of this research.

Development of 4D printed smart fresnel lenses: dynamic photochromic and UV-blocking capabilities via vat photopolymerization

- Light: Advanced Manufacturing , Article number: (2025)

- Received: 21 June 2024

- Revised: 10 December 2024

- Accepted: 22 December 2024 Published online: 06 March 2025

doi: https://doi.org/10.37188/lam.2025.011

Abstract: Advancements in additive manufacturing (AM) are revolutionizing 3D part production, making 3D printing crucial for creating optical devices like lenses and waveguides. This study employs vat photopolymerization (VPP) to fabricate adaptive 4D printed smart Fresnel lenses with photochromic properties using digital light processing (DLP). These lenses are fabricated with precise optical performance and geometric dimensions. Photochromic powders enable dynamic color changes upon UV exposure. The lenses were optically evaluated in both inactive and active states, demonstrating excellent UV and blue light blocking when inactive. Upon UV activation, the lenses darken and absorb parts of the visible light spectrum, with the degree of absorption and color change dependent on the photochromic material and its concentration. The lenses show minimal focal length errors, maintaining high precision and UV responsiveness even at low concentrations. This research highlights the lenses’ precision, UV responsiveness, blue light filtering capabilities, and stability after multiple UV exposure cycles. These findings underscore the potential of 4D printing in developing smart optical devices tailored for applications that demand dynamic light modulation and UV filtering, highlighting a combination of innovative manufacturing techniques and functional optics.

Research Summary

Additive Manufacturing: Transforming Functional Optics with Dynamic 4D Fresnel Lenses

Researchers at Khalifa University have developed switchable 4D printed Fresnel lenses with dynamic photochromic and UV-blocking properties using vat photopolymerization. These innovative lenses, fabricated via digital light processing, combine precise optical performance with adaptive color modulation. By integrating photochromic powders, the lenses darken under UV exposure, effectively filtering UV and visible light, while maintaining geometric accuracy and optical clarity. Their performance is stable across multiple UV cycles, offering durability and high functionality. Applications of these lenses span from dynamic light modulation to advanced UV filtering in optics, promising new frontiers in aerospace, healthcare, and wearable technologies. This work exemplifies the power of additive manufacturing in crafting multifunctional optical devices tailored for diverse applications.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article′s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article′s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

DownLoad:

DownLoad: