HTML

-

CCOS: Computer-controlled optical surfacing; EUV: Extreme ultraviolet; CA, Clear aperture; CAM: Computer-aided manufacturing; FIM, Function-form iterative method; FTM, Fourier transform method; RIFTA, Robust iterative Fourier transform-based dwell time optimization algorithm; RISE, Robust iterative surface extension dwell time optimization algorithm; MIM: Matrix-form iterative method; TSVD: Truncated singular value decomposition; LSQR: Least-squares with QR factorization; LSMR: Least-squares with MR factorization; CLLS: Constrained linear least-squares; UDO: Universal dwell time optimization method; NSO, Non-sequential optimization.

-

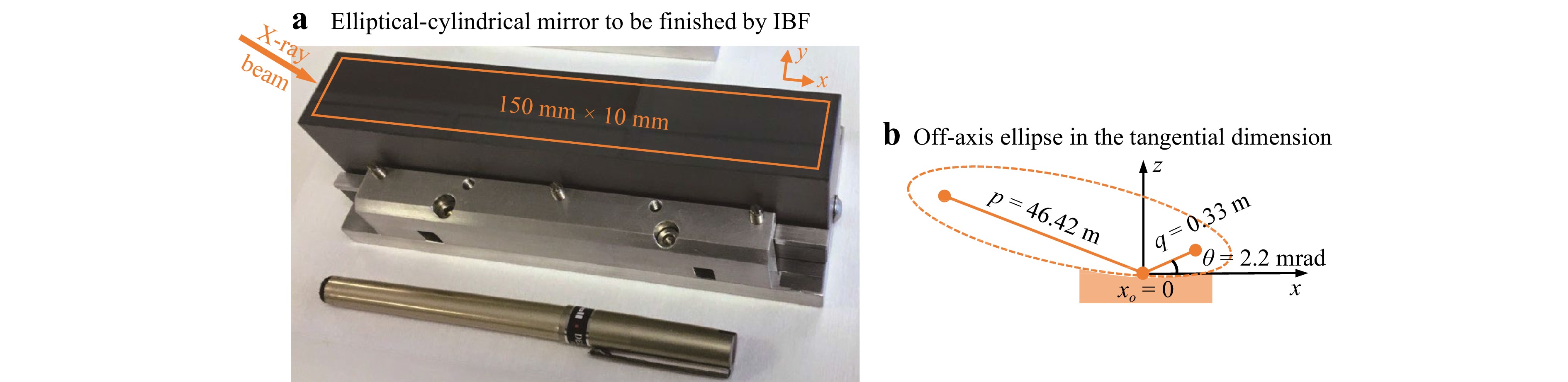

Over the past decade, precision machining technologies have rapidly developed, resulting in the increased amount of high-end optics in various applications such as telescopes for space exploration1, 2, extreme ultraviolet (EUV) lithography systems3, 4, synchrotron radiation and free-electron laser beamlines5, 6, and more. These optics require stringent specifications on surface precision and aspherical surface shapes to better compensate for aberrations6 and adapt to compact designs2, 7, which has led to the invalidation of conventional mechanical polishing methods and the emergence of computer-controlled optical surfacing (CCOS) technologies8, 9. Nowadays, most precision optical surfaces are manufactured using CCOS processes, which rely on computer control of machine tools to correct errors on an optical surface in a deterministic manner. The machine tool used in CCOS systems is much smaller than the clear aperture (CA), or effective area, within an optical surface, effectively reducing any local errors with feature sizes smaller than the machine tool stroke.

Since its inception by Jones in the 1970s10, numerous CCOS processes have been developed, including small-tool polishing11, 12, bonnet polishing13-15, magnetorheological finishing16-18, ion beam figuring (IBF)19-21, and fluid jet polishing (FJP)22-24. The choice of CCOS processes largely depends on the precision and target shape of the optical surfaces.

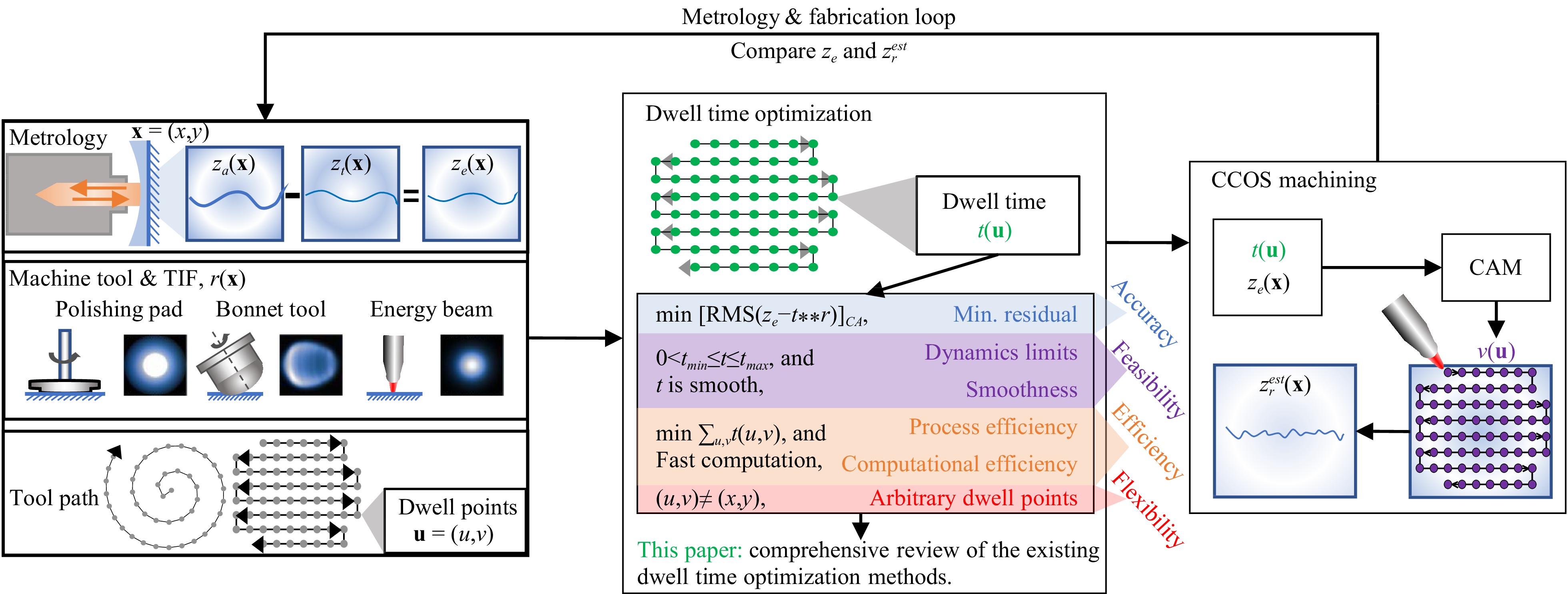

A typical CCOS process comprises a metrology-and-fabrication loop, as illustrated in Fig. 1, where $ {\bf{x}}=(x,y) $ is the surface coordinates. During the metrology phase, the actual surface shape $ z_{a}\left({\bf{x}}\right) $ is measured. The current surface error $ z_{e}\left({\bf{x}}\right) $ is calculated as the difference between $ z_{a}\left({\bf{x}}\right) $ and the target surface shape $ z_{t}\left({\bf{x}}\right) $. Combined with the Tool Influence Function (TIF) $ r({\bf{x}}) $ extracted from the machine tool and the pre-defined tool path $ {\bf{u}}=\left(u,v\right) $, a dwell time distribution $ t\left({\bf{u}}\right) $ is calculated, which is then converted to and fed as velocities $ v\left({\bf{u}}\right) $ in a Computer-Aided Manufacturing (CAM) software. This velocity distribution is then utilized to estimate the residual error $ z_{r}^{est}\left({\bf{x}}\right) $ and guide the motion of the machine tool over the optical surface to remove material. After each machining cycle, a new $ z_{e}\left({\bf{x}}\right) $ is measured and compared to $ z_{r}^{est}\left({\bf{x}}\right) $ to confirm the convergence of the process and determine if the target residual error requirement is satisfied.

Fig. 1 An iterative CCOS process is composed of metrology, machine tool influence function extraction, tool path planning, dwell time optimization and CCOS machining.

As shown in Fig. 1, the dwell time quality directly impacts the accuracy and convergence of a CCOS process. The dwell time solution is derived from Preston’s equation25, which models material removal per unit of time as

$$ {\dot z}\left({\bf{x}};t\right)=\kappa\cdot s\left({\bf{x}};t\right)\cdot f\left({\bf{x}};t\right) $$ (1) where $ {\dot z}\left({\bf{x}};t\right) $ is the partial derivative of $ z({\bf{x}};t) $ with respect to $ t $, $ \kappa $ is the Preston constant determined by the process parameters such as the material of the surface and abrasives, $ s\left({\bf{x}};t\right) $ and $ f\left({\bf{x}};t\right) $ are the pressure and relative velocity between the tool and the workpiece at the point $ {\bf{x}} $. By integrating Eq. 1 with respect to time and treating $ \kappa\cdot s\left({\bf{x}};t\right)\cdot f\left({\bf{x}};t\right) $ as a static TIF, in which $ t $ can be neglected, i.e. $ r\left({\bf{x}}\right)=\kappa\cdot s\left({\bf{x}}\right)\cdot f\left({\bf{x}}\right) $, a two-dimensional (2D) convolutional material removal model8, 10 is obtained, where the removed material $ z\left({\bf{x}}\right) $ is modeled as the convolution between the static TIF $ r\left({\bf{x}}\right) $ and the dwell time $ t\left({\bf{x}}\right) $, given by:

$$ z\left({\bf{x}}\right)=r\left({\bf{x}}\right)** t\left({\bf{x}}\right) $$ (2) where “$ ** $” denotes the 2D convolution operation. Eq. 2 is also called a linear and shift-invariant system, where the TIF is assumed to be temporally and spatially stable, and the material removal is linear with respect to the dwell time. Replacing $ z\left({\bf{x}}\right) $ by $ z_{e}\left({\bf{x}}\right) $ in Eq. 2, $ t\left({\bf{x}}\right) $ can be estimated through deconvolution. However, since deconvolution is an ill-posed inverse problem without a unique solution, $ t\left({\bf{x}}\right) $ can only be obtained by optimization. The field of 2D deconvolution has been widely explored in image super-resolution26 and restoration27, and many of the practical concepts have been applied to dwell time optimization10, 20, 28. Nonetheless, as highlighted in Fig. 1, dwell time optimization has specific objectives that differ from those of image restoration and super-resolution.

● Accuracy: Image restoration and dwell time optimization approaches aim to minimize the residual error between the actual signal and the deconvolved signal. However, dwell time optimization focuses on minimizing the residual error in the CA, $ [z_{e}\left({\bf{x}}\right)-r\left({\bf{x}}\right)** t\left({\bf{x}}\right)]_{CA} $, where $ [\cdot]_{CA} $ denotes an argument in the CA.

● Feasibility: Two aspects should be considered to make the optimization feasible for actual fabrication: 1) Positivity and dynamics limits considerations. It is important to note that the dwell time $ t\left({\bf{x}}\right) $ should always be positive and constrained by $ t_{min} $ and $ t_{max} $, where $ 0<t_{min}\leq t\left({\bf{x}}\right)\leq t_{max} $, since most CCOS processes are material removal processes. These constraints are unnecessary for general image deconvolution. Also, the lower and upper limits, $ t_{min} $ and $ t_{max} $, respectively, indicate that the optimization of dwell time must consider the constrains of machine dynamics, such as maximum speeds and accelerations29, 30. 2) Smoothness. The restored image in image deconvolution contains more details (i.e., higher-frequency components) than the captured image. However, in the optimization of dwell time, $ t\left({\bf{x}}\right) $ must smoothly duplicate the shape of $ z_{e}\left({\bf{x}}\right) $31. Any higher-frequency components are not expected in a dwell time solution, as they may result in frequent accelerations and decelerations that could compromise the stability of the CCOS process32. These two aspects together define the feasibility of a dwell time solution.

● Efficiency: Efficiency is composed of process efficiency and computational efficiency. 1) Achieving the target residual error with the shortest possible total dwell time is crucial to ensure process efficiency, particularly in large optics fabrication, which can take months or years to complete2. 2) the computational cost of obtaining a valid dwell time solution must also be reasonable.

● Flexibility: As shown in Fig. 1, the dwell points $ {\bf{u}} $ are expected to be freely distributed over the surface coordinates $ {\bf{x}} $. This is different from image deconvolution, where the coordinates of the actual image and the restored image overlap with each other. The flexibility of having arbitrary dwell points is essential, as it enables the usage of advanced tool paths33-35 to reduce the generation of periodic, middle-frequency errors, which can be hard to remove36.

In actual CCOS processes, achieving all these objectives simultaneously is challenging. The machine dynamics constraints, for instance, can affect the accuracy of the process since the planned dwell time may not be realizable by the machine. While it is possible to optimize the machining process for minimized middle-frequency errors and maximum efficiency by carefully selecting the dwell points, this may impact the overall accuracy and incur additional computation cost. Therefore, a balance must be struck among accuracy, feasibility, efficiency, and flexibility.

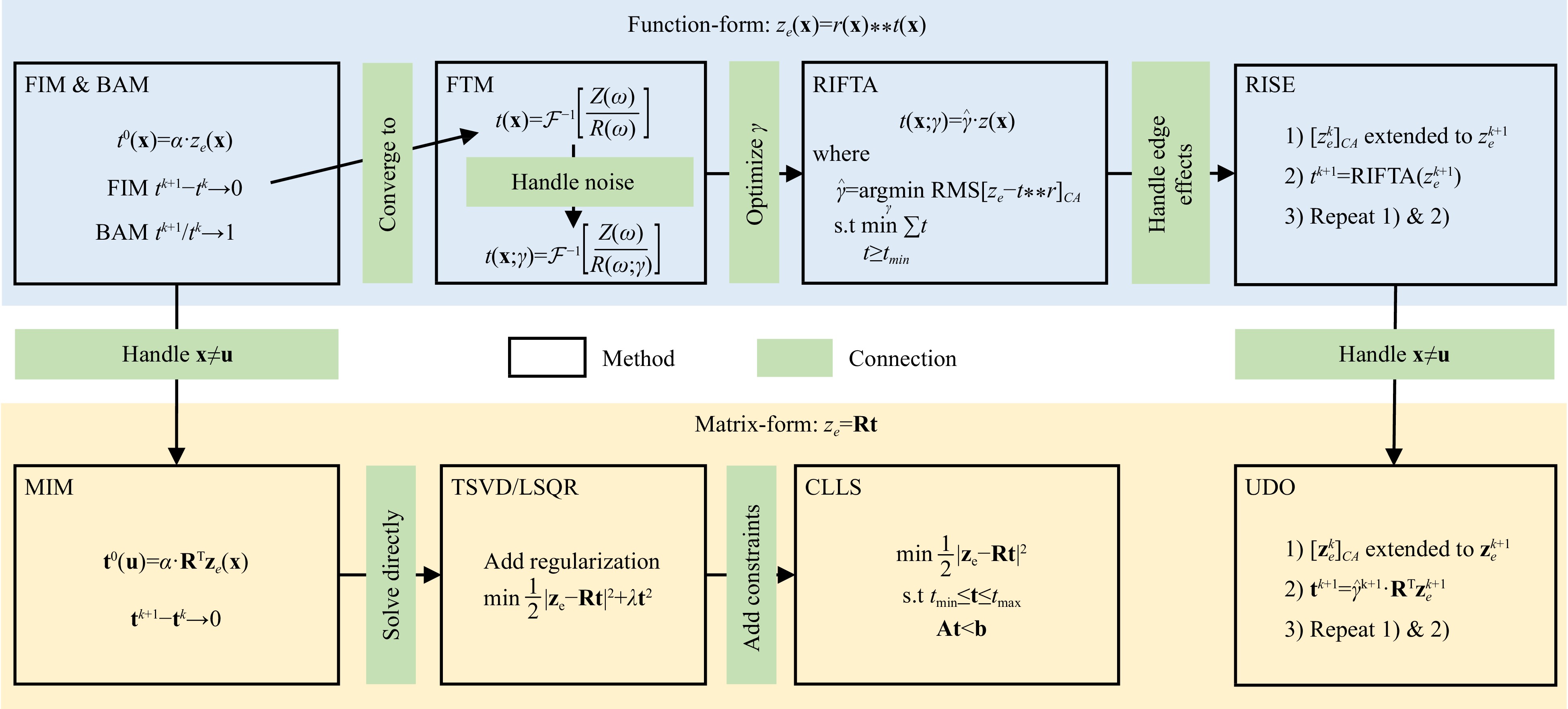

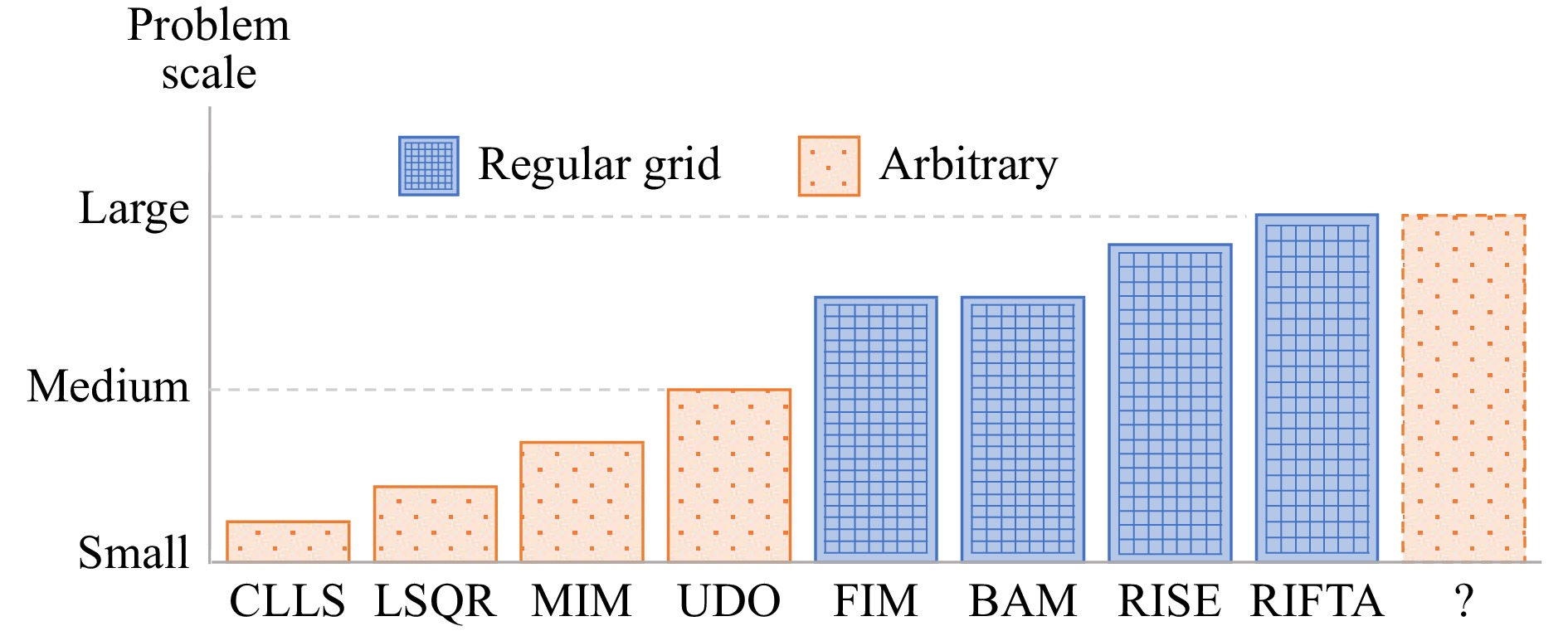

Researchers have proposed a range of dwell time optimization methods to address the challenge of achieving the various objectives in CCOS processes. We classify these methods into two categories, namely the function-form and matrix-form methods, as illustrated in Fig. 2. Each category addresses different scenarios and distributions of dwell points relative to the surface coordinate grid, x, defined by the optical surface. The function-form methods directly tackle the convolution function in Eq. 2 under the assumption that the dwell points are distributed on the same coordinate grid defined by the surface. The matrix-form methods handle the cases in which the dwell points are arbitrarily distributed by discretizing Eq. 2 as

Fig. 2 Links among the existing dwell time optimization methods, where $ {\cal{F}}^{-1} $ denotes inverse Fourier transform, $ \alpha $ and $ \gamma $ are constant scalars, and $ {\boldsymbol{\omega}} $ denotes the frequency components.

$$ z_{e}\left({\bf{x}}_{j}\right)=\sum\limits_{i=0}^{N_{t}-1}r\left({\bf{x}}_{j}-{\bf{u}}_{i}\right)\cdot t\left({\bf{u}}_{i}\right) $$ (3) for $ j=0,1,...,N_{z}-1 $, where $ N_{z} $ is the number of elements in $ z_{e}\left({\bf{x}}_{j}\right) $, $ N_{t} $ is the number of dwell points, $ {\bf{u}}_{i} $ is the $ i $th dwell point, and $ r\left({\bf{x}}_{j}-{\bf{u}}_{i}\right) $ represents the material removed per unit of time at the point $ {\bf{x}}_{j} $ when the TIF dwells at $ {\bf{u}}_{i} $. Eq. 3 indicates that the coordinates defining the optical surface and dwell points can vary. It is usually rewritten in a matrix form as

$$\underbrace{\left(\begin{array}{c}z_{e_0} \\ z_{e_1} \\ \vdots \\ z_{e_{N_z-1}}\end{array}\right)}_{{\bf{z}}_{{\bf{e}}}}=\underbrace{\left(\begin{array}{*{20}{c}} {r_{0,0} } & { r_{0,1} } & { \cdots } & { r_{0, N_t-1} }\\ {r_{1,0} } & { r_{1,1} } & { \cdots } & { r_{1, N_t-1} }\\{ \vdots } & { \vdots } & { \vdots } & { \vdots }\\{ r_{N_z-1,0} } & { r_{N_z-1,1} } & { \cdots } & { r_{N_z-1, N_t-1} }\end{array}\right)}_{{\bf{R}}} \underbrace{\left(\begin{array}{c} t_0 \\ t_1 \\ \vdots \\ t_{N_t-1}\end{array}\right)}_{{\bf{t}}}$$ (4) where $ {\bf{R}} $ is a rectangular matrix when the numbers of elements in $ z_{e}\left({\bf{x}}\right) $ and $ t\left({\bf{u}}\right) $ vary. In this context, we refer to the methods that manipulates the matrix $ {\bf{R}} $ as the matrix-form methods.

The function-form methods include the function-form iterative method (FIM)10, 37-41, Bayesian method (BAM)28, 42, Fourier transform methods (FTM)20, 38, 43, robust iterative Fourier transform-based dwell time optimization algorithm (RIFTA)44, robust iterative surface extension-based method (RISE)45, and others46-48. The matrix-form methods comprise the matrix-form iterative method (MIM)49, Tikhonov-regularized methods11, 16, 17, 29-31, 50-58, constrained linear least-squares methods (CLLS)30, 59, 60, and universal dwell time optimization method (UDO)32. Based on these matrix-form methods, modeling the surface error using Zernike polynomials61 or B-splines62 before dwell time optimization help obtain smoother dwell time solutions while maintaining a relatively sparser and more computationally efficient dwell time solver. Although these methods were developed independently and prioritized different objectives illustrated in Fig. 1, they share similar principles and strategies. This study aims to provide a comprehensive review by exploiting the intrinsic links among the existing dwell time optimization methods, providing insights on their proper implementations, evaluating their performances, and combining them to form a universal dwell time optimization methodology. The reviewed methods are assessed with a simulation study and an actual experiment, facilitating their more straightforward application in various precision optical fabrication processes.

The rest of this paper is organized as follows. Section 2 covers the function-form methods, providing a step-by-step explanation of the principles, the connections among different approaches, our insights on their optimized implementations, and their performance evaluations. Section 3 then discusses the matrix-form methods in the same manner. In Section 4, strategies used in existing methods to achieve accuracy, feasibility, efficiency, and flexibility are summarized, leading to the development of a complete dwell time optimization methodology. Section 5 presents an experiment applying all the reviewed methods in an actual CCOS process, followed by a discussion on selecting a proper dwell time optimization method in Section 6. Section 7 concludes the paper.

-

The function-form and matrix-form methods are reviewed in detail in Sections 2 and 3, respectively. The review process thoroughly explains each method's theoretical aspects, followed by performance evaluation through simulation. Fairness in this simulation is ensured through three aspects.

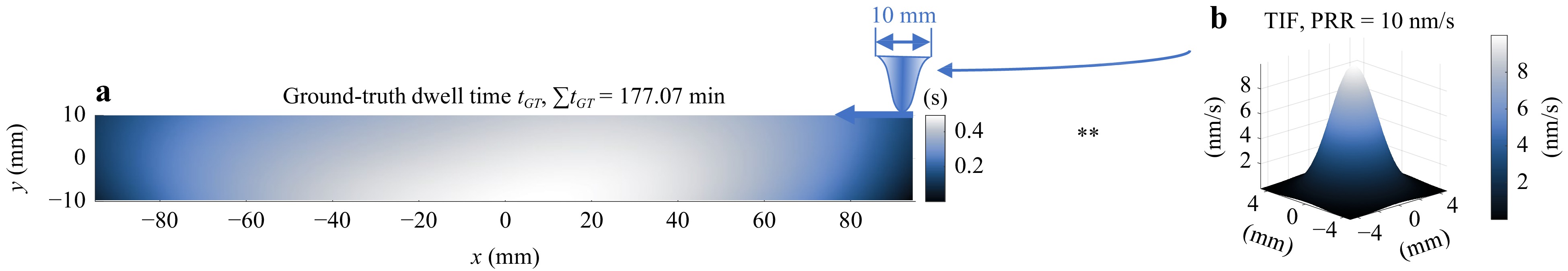

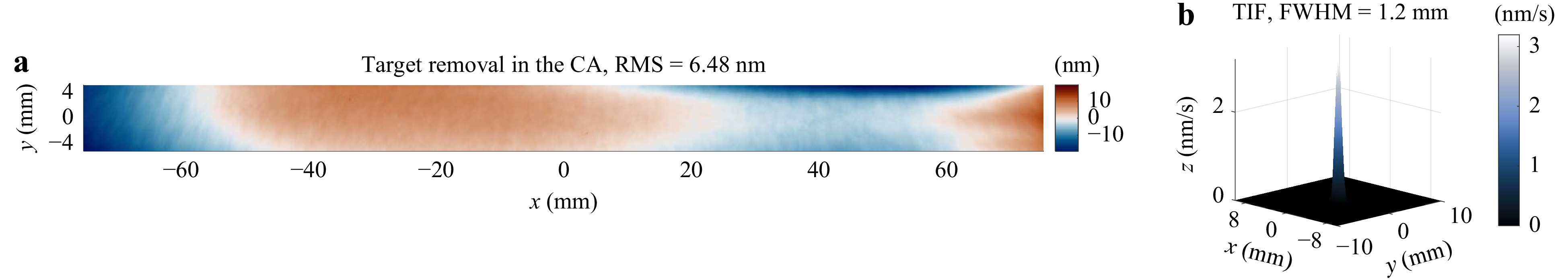

Firstly, as shown in Fig. 3a, a ground-truth dwell time solution $ t_{GT}\left({\bf{x}}\right) $ is generated using the first 144 Chebyshev polynomials. The spatial resolution for $ {\bf{x}} $ in $ t_{GT}\left({\bf{x}}\right) $ is set as 0.36 mm and the size of $ t_{GT}\left({\bf{x}}\right) $ is 20 mm × 190 mm, thus the number of dwell points is 56 × 525 = 29,400. Considering the dynamics constraints of the machine, zero dwell time cannot be implemented, and thus a $ t_{min} $ of 1.4 ms, which is calculated based on the IBF machine dynamics21, is added to each point in $ t_{GT}\left({\bf{x}}\right) $. A Gaussian TIF $ r\left({\bf{x}}\right) $ with standard deviation of $ \sigma=1.6 $ mm and a peak removal rate (PRR) equal to 10 nm/s is given in Fig. 3b, which is convoluted with $ t_{GT}\left({\bf{x}}\right) $ to generate the nominal target removal shown in Fig. 4a. This target removal thus can be perfectly achieved by $ t_{GT}\left({\bf{x}}\right) $. The dwell time solutions restored using different dwell time optimization methods will be compared to $ t_{GT}\left({\bf{x}}\right) $.

Fig. 3 The ground-truth dwell time $ t_{GT} $ a is generated by the first 144 Chebyshev polynomials. It is convoluted with a Gaussian tool influence function (TIF) b to generate the nominal removal map used in the simulation.

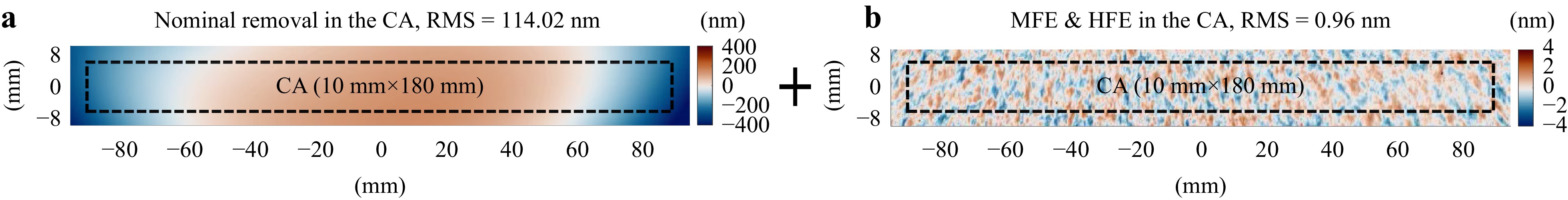

Fig. 4 The nominal target removal a generated using the dwell time and TIF shown in Fig. 3. The middle-frequency error (MFE) and high-frequency error (HFE) b are extracted from a pitch-polished mirror and added to a. The clear aperture (CA) is taken to be smaller than the outermost perimeters of the nominal target removal map by the radius of the TIF.

Secondly, we add the middle-frequency error (MFE) and high-frequency error (HFE) to the nominal target removal to simulate their influence in restoring the dwell time solution, as shown in Fig. 4b. These errors are extracted from a pitch-polished flat mirror using a high-pass Gaussian filter with a cut-off wavelength of 10 mm, equal to the TIF's diameter. These MFE and HFE thus cannot be corrected using this TIF with $ t_{GT}\left({\bf{x}}\right) $. All the dwell time optimization methods are first applied to the noise-free nominal target removal map to examine their methodological performances, then their robustness in handling MFE, HFE, and noisy data.

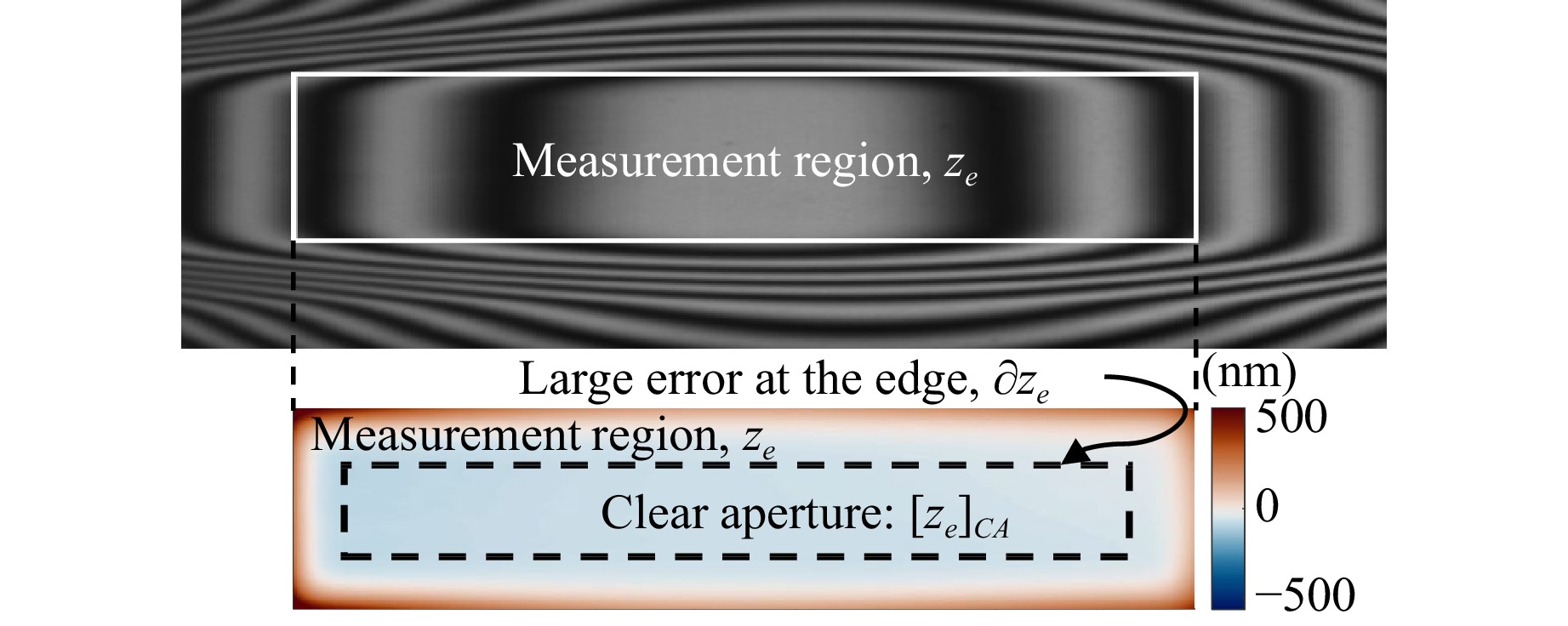

Lastly, to avoid the influence of edge effects41, the calculation area $ z_{e}\left({\bf{x}}\right) $ is defined to be larger than the CA by the radius of the TIF on each side of its perimeter, but only the estimated residual errors in the CA are compared. All the iterative dwell time optimization methods are kept running until the absolute root mean square (RMS) difference between the last two consecutive iterations is less than 0.01 nm. The results for each method will be demonstrated, both with and without MFE and HFE.

-

The additive FIM (from now on referred to as FIM) was first introduced to CCOS by Jones in 197710, following Van Cittert’s original proposal in 193163. In FIM, as shown in Fig. 2, the initial guess to $ t\left({\bf{x}}\right) $ is taken as

$$ t^{0}\left({{\bf{x}}}\right)=\alpha\cdot z_{e}\left({\bf{x}}\right) $$ (5) where $ \alpha>0 $ is a scalar. The subsequent iterative updates of $ t\left({{\bf{x}}}\right) $ take the form of

$$ t^{k+1}\left({\bf{x}}\right)=t^{k}\left({\bf{x}}\right)+\beta\left[z_{e}\left({\bf{x}}\right)-t^{k}\left({\bf{x}}\right)** r\left({\bf{x}}\right)\right] $$ (6) where $ \beta>0 $ is a learning rate that controls the convergence speed and $ k\in\mathbb{Z} $. Eq. 6 indicates that the new dwell time distribution is updated using the residual between $ z_{e}\left({\bf{x}}\right) $ and the convolution of the previous dwell time and the TIF. As shown in Fig. 2, an absolute convergence is pursued in the FIM, meaning that the difference between $ t^{k+1}\left({\bf{x}}\right) $ and $ t^{k}\left({\bf{x}}\right) $ approaches zero at the convergence. However, this update rule poses several challenges in attaining this ultimate convergence.

Firstly, selecting parameters $ \alpha $ and $\, \beta $ is crucial for accuracy and convergence speed. In the conventional Van Cittert’s formula63, 64, values of $ \alpha=\beta=1 $ were used in many applications like image restoration, where pixel intensity values are normalized to be within $ [0,1] $ and the actual and recovered images share the same unit. However, in CCOS, $ t\left({\bf{x}}\right) $ and $ z_{e}\left({\bf{x}}\right) $ have different units (e.g., seconds vs. nm). Therefore, using the unities for $ \alpha $ and $ \beta $ is not optimal65. Although $ \alpha=1 $ was still used in the initial CCOS process10, it affects the dwell time accuracy and slows down the convergence rate since $ t^{0} $ may be far from the final solution. A better $ t^{0} $ in CCOS can be determined by normalizing $ z_{e}\left({\bf{x}}\right) $ by the volumetric removal rate (VRR) of the TIF $ r\left({\bf{x}}\right) $40, 41, which is defined as

$$ {\rm{VRR}}=\int_{\Omega}r\left({\bf{x}}\right)d{\bf{x}} $$ (7) where $ \Omega $ is the area of the TIF. Note that in discretized implementation of Eq. 7, x is sampled in the pixel space by a measurement instrument equipped with a charge-coupled device. Therefore, VRR can be approximated by a summation of all the elements in $ r\left({\bf{x}}\right) $. The initial dwell time $ t^{0}\left({\bf{x}}\right) $ is then expressed as

$$ t^{0}\left({{\bf{x}}}\right)=\frac{z_{e}\left({\bf{x}}\right)}{{\rm{VRR}}} $$ (8) where $ \alpha=1/{\rm{VRR}} $. The philosophy behind this normalization is that the $ {\rm{VRR}} $ of $ r\left({\bf{x}}\right) $ can also be written as $ \left|R\left({\boldsymbol{\omega}}={\bf{0}}\right)\right| $ where $ R\left({\boldsymbol{\omega}}\right) $ is the Fourier transform of $ r\left({\bf{x}}\right) $, which makes the use of Eq. 8 equivalent to using a normalized $ r\left({\bf{x}}\right) $ with

$$ \left|R\left({\boldsymbol{\omega}}={\bf{0}}\right)\right|=\int_{\Omega}r\left({\bf{x}}\right)d{\bf{x}}=1 $$ to generate the initial guess. Eq. 8 ensures that the volume of the deconvolved $ t^{0} $ is correct, which is critical for the convergence of the subsequent iterative refinements64.

The convergence speed is controlled by the learning rate $ \,\beta $, also called the over-relaxation parameter40, 41, 65-67, for it improves the speed of convergence of Eq. 7 if set correctly. It has been proven that the reasonable value of $ \,\beta $ ensuring the convergence is situated in the range $ (0,2] $ if the normalization in Eq. 8 is adopted66, 67. Finding the optimal $\, \beta $ requires minimizing the maximum value of $ \left|1-\beta\cdot R\left({\boldsymbol{\omega}}\right)\right| $, which results in $ \,\beta=2 $ for a low-pass system with $ R\left({\boldsymbol{\omega}}\right) $ real and non-negative67. This is the first merit of why a Gaussian $ r\left({\bf{x}}\right) $ is preferred in CCOS: the Fourier transform of a Gaussian TIF is still a Gaussian in the frequency domain. However, in actual CCOS processes, such an ideal TIF is rare, and $ R\left({\boldsymbol{\omega}}\right) $ is always complex, so finding the optimal $\, \beta $ is rather complicated. To ease the turning of $\, \beta $, an adaptive iteration scheme was proposed, in which another parameter $ \eta\in(0,1) $ was introduced to reduce $ \,\beta $41 as

$$ \beta\gets\eta\cdot\beta $$ (9) when Eq. 6 begins to diverge. In detail, $ \,\beta $ is initialized with a constant in $ (0,2] $, usually with $ \,\beta=1 $ for the balance between the accuracy and convergence speed. Afterward, during the iterative refinements, the residual errors in the CA are estimated from the current and previous dwell time distributions, which are defined as $ {\rm{RMS}}_{CA}^{k+1}={\rm{RMS}}\left[z_{e}\left({\bf{x}}\right)- t^{k+1}\left({\bf{x}}\right)** r\left({\bf{x}}\right)\right]_{CA} $ and $ {\rm{RMS}}_{CA}^{k}={\rm{RMS}}\left[z_{e}\left({\bf{x}}\right)- t^{k}\left({\bf{x}}\right)** r\left({\bf{x}}\right)\right]_{CA} $, respectively, are compared. If $ {\rm{RMS}}_{CA}^{k+1}\geq{\rm{RMS}}_{CA}^{k} $, it indicates that the iterative refinement process is diverging, and Eq. 9 is executed to reduce $ \,\beta $. The iterative update is then retried with the new $ \,\beta $ until either $ {\rm{RMS}}_{CA}^{k+1}<{\rm{RMS}}_{CA}^{k} $ or a maximum number of trials is reached. As claimed in Ref. 41, this adaptive scheme eliminates the need for manual adjustment of $ \,\beta $ and automates the FIM.

The impact of $ r\left({\bf{x}}\right) $ on the convergence of FIM is also worth exploring. From the comprehensive convergence criteria related to $ r\left({\bf{x}}\right) $ derived in Ref. 64, two crucial necessary conditions (NC) can be summarized. Without loss of generality, $ {\bf{x}}={\bf{0}} $ is defined as the center of $ r\left({\bf{x}}\right) $.

The first NC of the convergence requires that $ r\left({\bf{x}}\right) $ has a solid central peak, i.e., the maximum value of $ r\left({\bf{x}}\right) $ must occur uniquely at $ {\bf{x}}={\bf{0}} $. This condition is expressed as:

$$ {\rm{NC1}}:\; \left|r\left({\bf{x}}\right)\right|<r\left({\bf{0}}\right),\; {\bf{x}}\neq{\bf{0}} $$ (10) The second NC demands that each even derivative of $ r\left({\bf{x}}\right) $ should have its absolute extremum at $ {\bf{x}}={\bf{0}} $, and there should be no singularities in these even derivatives, as indicated in Eq. 11:

$$ {\rm{NC2}}:\; \left| r^{(n)}\left({\bf{x}}\right)\right|<\left| r^{(n)}\left({\bf{0}}\right)\right|,\; {\bf{x}}\neq{\bf{0}},\; {\rm{and}}\; \left(j\right)^{n}r^{(n)}\left({\bf{0}}\right)>{\bf{0}} $$ (11) where $ r^{(n)}\left({\bf{x}}\right) $ is the $ n $th derivative of $ r\left({\bf{x}}\right) $ for $ n=0,2,4,... $ and $ j=\sqrt{-1} $. Together, NC1 and NC2 result in the second reason why a Gaussian TIF is ideal in CCOS processes: it automatically satisfies both conditions.

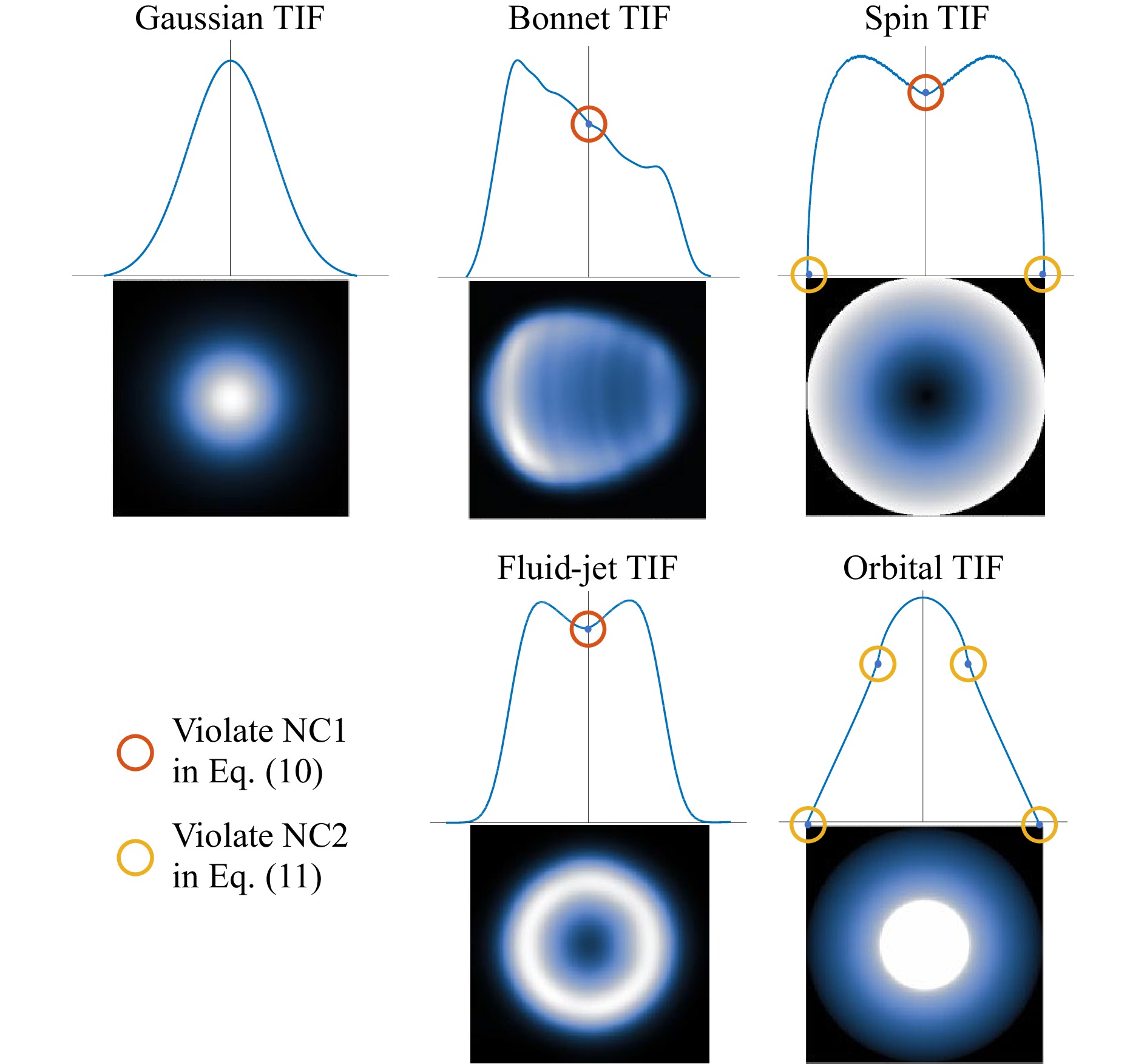

A Gaussian TIF is a rotationally symmetric function with respect to the central peak, and its even derivatives are always continuous. To further illustrate this point, Fig. 5 shows the one-dimensional TIF profiles of an ideal Gaussian TIF versus other common TIFs found in CCOS processes. The bonnet58, spin68, and fluid-jet49 TIFs violate NC1 since they either have a biased peak location or peaks are not unique. The spin and orbital68, 69 TIFs do not satisfy NC2, as their functions end abruptly, and the second derivatives are singular. The orbital TIF is also a piecewise function with discontinuous even derivatives at the transition points. All these aspects affect the convergence of the iterative routine in Eq. 6. As shown in the following sections, the other methods are derived from FIM. Therefore, the convergence analysis described above applies to those methods.

Fig. 5 One-dimensional tool influence function (TIF) profiles of the Gaussian, bonnet, spin, fluid-jet, and orbital TIFs. The points that lead to divergence are circulated.

Finally, the refinement in Eq. 6 brings edge effects to the final dwell time solution. As illustrated in Fig. 4, the convolution $ t^{k}\left({\bf{x}}\right)** r\left({\bf{x}}\right) $ is only well-defined in a region which is at least smaller than the $ z_{e}\left({\bf{x}}\right) $ by the radius of a TIF on each side of its perimeter, denoted by $ \left[z_{e}\left({\bf{x}}\right)\right]_{CA} $. Consequently, FIM yields large dwell time values along the edges of the region, which can lead to inaccurate results. If $ z_{e}\left({\bf{x}}\right) $ is defined as the entire area of the nominal removal shown in Fig. 4, the ground-truth dwell time given in Fig. 3a will not be fully recovered by FIM. To avoid this issue, it is necessary to choose a $ z_{e}\left({\bf{x}}\right) $ that is at least larger than the CA by the diameter (rather than the radius) of the TIF. If the extra area is unavailable during measurement, surface extrapolation32, 45, 70, 71 is necessary to generate the missing data before applying the FIM. It is worth noting that, in this study, to ensure fair comparison without edge effects, we analytically extend the nominal removal maps shown in Fig. 4 by the radius of the TIF on each side before applying FIM. The same process will be used for BAM, RIFTA and MIM. By implementing these measures, the dwell time optimization methods reviewed in this study will be more appropriately compared.

-

Achieving the absolute convergence of FIM in actual CCOS processes is challenging. To enhance the robustness of FIM in practice, an optimized implementation of FIM is demonstrated in Algorithm 1, which incorporates three key strategies to ensure reasonable convergence.

Firstly, the adaptive parameter tuning approach41 is adopted, wherein the learning rate $ \,\beta $ is reduced, and the update refinement is retried when the routine begins to diverge. In this study, $ \,\beta $ and $ \gamma $ are initialized to be $ \,\beta=2 $67 and $ \eta=0.95 $41, respectively, as shown in Line 2 in Algorithm 1.

Secondly, we introduce an early stop mechanism that employs the desired error RMS $ \epsilon $ as a threshold, as shown in Line 7 of Algorithm 1. This mechanism was not mentioned in the existing FIM methods. However, in practice, it helps terminate the loop early if the current dwell time solution is already satisfactory, offering two advantages. First, it prevents the dwell time solution from deviating significantly due to the influence of noise when the number of iterations is large. This merit ensures that the result remains reasonable and is less susceptible to inaccuracies arising from noise or other sources of variation. Additionally, the early stop mechanism helps avoid unnecessary iterations, reducing the computational burden and accelerating the convergence of the optimization procedure.

Thirdly, following Ref. 41, a maximum number of iterations $ N $ is set to limit the total number of trials. If the desired error RMS cannot be achieved after $ N $ iterations, the last (and best) dwell time solution is accepted.

The FIM implementation shown in Algorithm 1 achieves improved convergence performance and robustness by implementing these three strategies. Also, the convolution in Line 5 in each iteration can be accelerated by a fast Fourier transform (FFT) so that FIM is computationally efficient and can be applied to large-scale problems in CCOS processes.

-

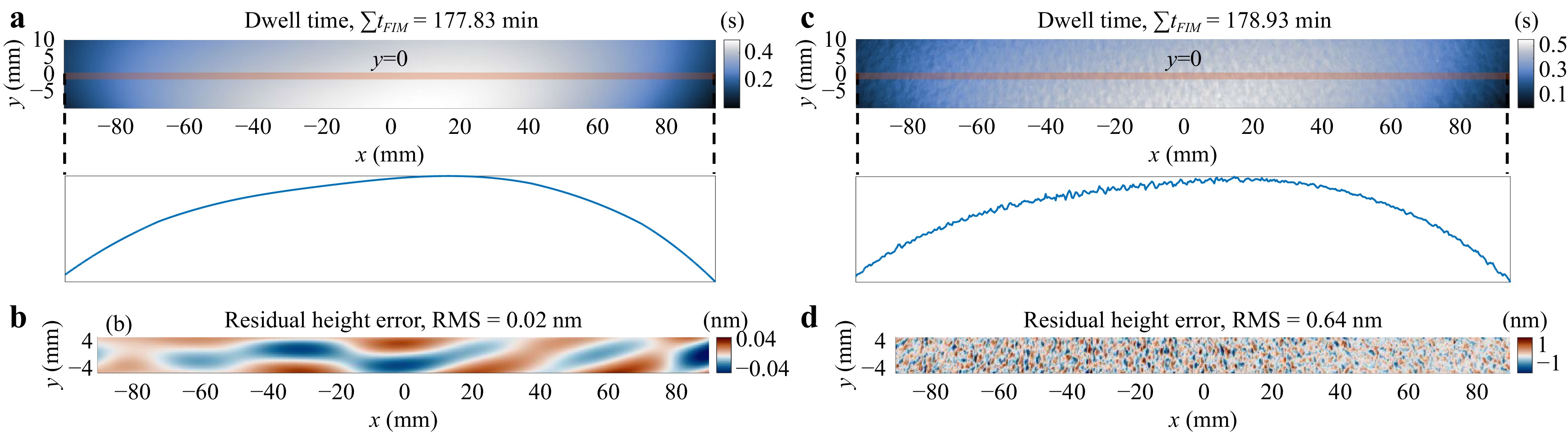

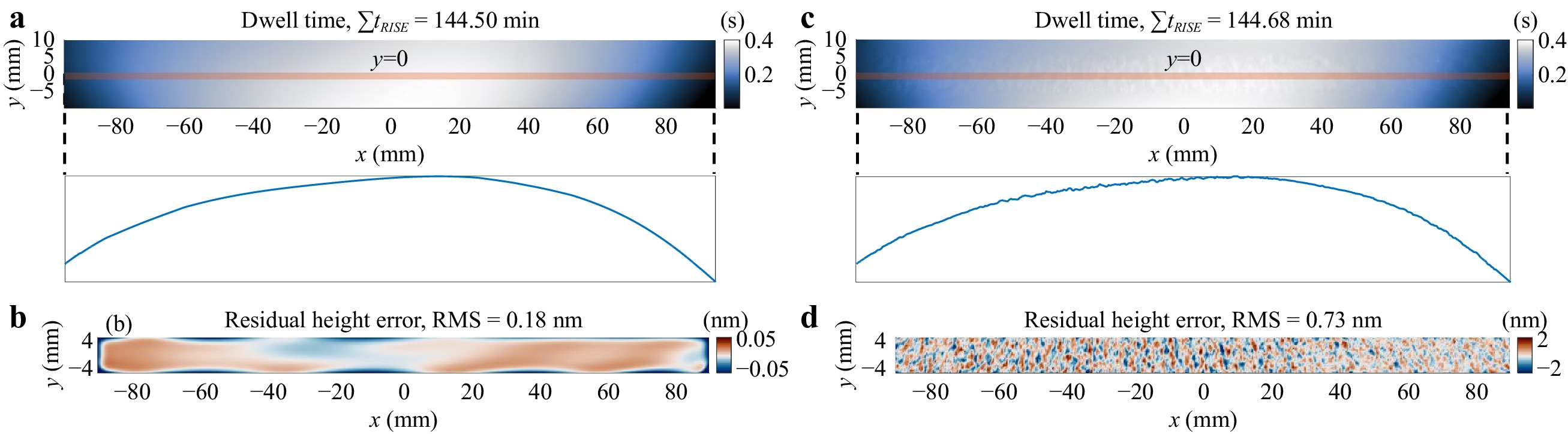

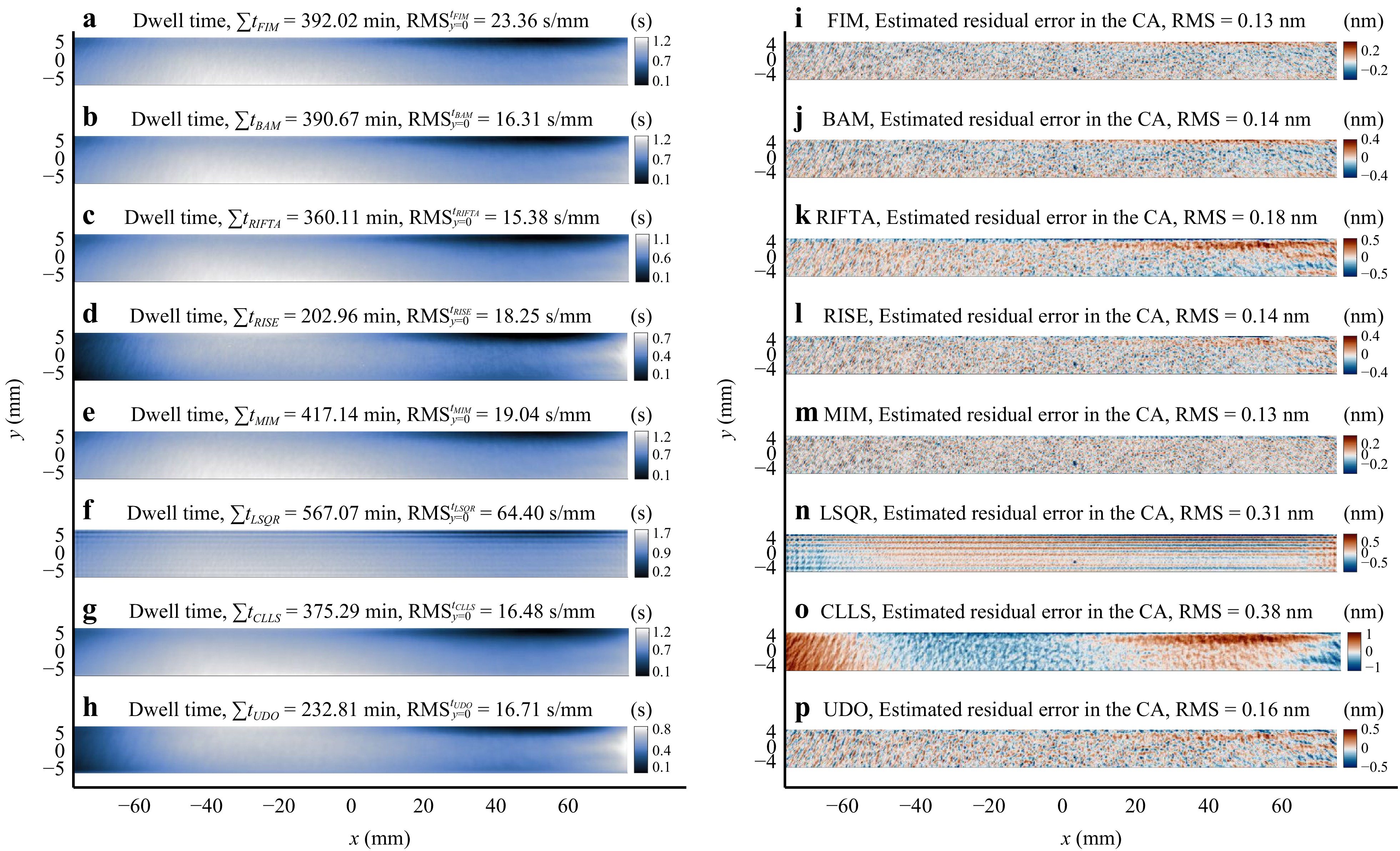

Algorithm 1 is first examined on the nominal removal shown in Fig. 4a without MFE and HFE. The resulting dwell time $ t_{FIM} $ and estimated residual height error in the CA are demonstrated in Figs. 6a, b, respectively. After 20 iterations, $ t_{FIM} $ closely replicates the shape of the nominal removal, with only 0.4% longer than the ground truth. The residual error in the CA is only 0.02 nm RMS, indicating that FIM converged to the ground-truth solution in this MFE-HFE-free case.

Fig. 6 Dwell time and residual height errors calculated using FIM. a, b are the dwell time and residual height errors without the middle-frequency error (MFE) and high-frequency-error (HFE), respectively. c, d are the dwell time and residual height errors with MFE and HFE, respectively. It is evident that MFE and HFE result in unsmooth dwell time.

When MFE and HFE were added, as shown in Fig. 6c, d, the calculated $ t_{FIM} $ still replicated the shape of the nominal removal and was close to the ground truth regarding the total dwell time. However, the dwell time map shown in Fig. 6c contained frequent spikes, as seen from the one-dimensional profile at $ y=0 $, which indicates that MFE and HFE lead to unsmooth dwell time. While it is possible to correct the added MFE and HFE by this dwell time to some extent, as shown in Fig. 6d, this may not be practical in actual CCOS processes since the spikes cause frequent acceleration and deceleration, which can stress the machine dynamics. A possible solution to mitigate the influence of MFE and HFE is to stop the iterative routine early once the gradients of the deconvolved dwell time exceed a certain threshold. However, determining this threshold is challenging, as it depends on the initial surface error and TIF properties. The merits of FIM are its simplicity and the well-studied convergence criteria, which lay the foundation of the other more advanced dwell time optimization methods that will be reviewed in the following sections.

-

We move on from FIM to BAM. As illustrated in Fig. 2, the main difference between FIM and BAM in their final formats is that a relative convergence, $ t^{k+1}/t^{k}\rightarrow1 $, is pursued in BAM instead of the absolute convergence, $ t^{k+1}-t^{k}\rightarrow0 $, in FIM. This relative convergence form results from modeling deconvolution as a Bayesian process. Specifically, in BAM, the noise is modeled as a Poisson distribution, which simplifies BAM and increases the smoothness of dwell time. The principle behind BAM and its derivation are explained in the rest of this section.

Due to the deconvolution problem's ill-posed nature, any measurement errors can be magnified and lead to undesirable results, as illustrated in Fig. 6c. To address this issue, researchers in astronomy often employ statistical estimation methods, such as BAM, for image restoration purposes72-74. BAM, particularly the Richardson-Lucy (R-L) algorithm73, 74, was introduced to solve dwell time for IBF in 200928, 42. BAM starts by defining a prior distribution $ P\left(t\right) $ over the true dwell time $ t\left({\bf{x}}\right) $, which incorporates the expected structure of the dwell time. Additionally, the probability distribution of the target removal $ z_{e}\left(x\right) $, given the true dwell time $ t\left({\bf{x}}\right) $, $ P\left(z_{e}|t\right) $, needs to be specified. Following the Bayesian paradigm, the inference towards the true $ t\left(x\right) $ should be based on $ P\left(t|z_{e}\right) $, which is defined as

$$ P\left(t|z_{e}\right) = \frac{P\left(z_{e}|t\right)\cdot P\left(t\right)}{P\left(z_{e}\right)}\propto P\left(z_{e}|t\right)\cdot P\left(t\right) $$ (12) where $ P\left(z_{e}\right) $ is the marginal probability of $ z_{e}\left({\bf{x}}\right) $ and can be omitted as it is independent of $ t $. Since the true dwell time $ t\left({\bf{x}}\right) $ is unknown, an estimate $ \hat{t}\left({\bf{x}}\right) $ can be obtained by maximizing the posterior probability as

$$ \hat{t}=\underset{t}{{\rm{argmax}}}\; P\left(t|z_{e}\right)=\underset{t}{{\rm{argmax}}}\; P\left(z_{e}|t\right)\cdot P\left(t\right) $$ (13) which can also be expressed in the form of the minimum negative log-likelihood as

$$ \hat{t}=\underset{t}{{\rm{argmin}}}\; L_{1}\left(t\right)=\underset{t}{{\rm{argmin}}}\; \left[-{\rm{log}}P\left(z_{e}|t\right)-{\rm{log}}P\left(t\right)\right] $$ (14) where $ L_{1}\left(t\right)=-{\rm{log}}P\left(z_{e}|t\right)-{\rm{log}}P\left(t\right) $ is the loss function, $ -{\rm{log}}P\left(z_{e}|t\right) $ is the data log-likelihood and $ -{\rm{log}}P\left(t\right) $ is a penalty term. In R-L, a non-informative prior is assumed, i.e., $ P\left(t\right)={\rm{const}} $. Therefore, the second term in Eq. 14 can be neglected. Furthermore, since most metrology instruments use charge-coupled device detectors, each component of $ P\left(z_{e}|t\right) $ is assumed to follow a Poisson distribution with the parameter $ r** t $ in R-L28, 42, 72. With this assumption, a loss function $ L_{1} $ is obtained from Eq. 14 as

$$ L_{1}\left(t\right)=\sum\limits_{i=1}^{M}\left[\left(r** t\right)-z_{e}\left({\bf{x}}_{i}\right)\cdot{\rm{log}}\left(r** t\right)-{\rm{log}}\; z_{e}\left({\bf{x}}_i\right)\right] $$ Since $ -{\rm{log}}\; z_{e}\left({\bf{x}}_i\right) $ is independent of $ t $, it can be eliminated from $ L_{1}\left(t\right) $ and thus, the final $ L_{1}\left(t\right) $ is written as

$$ L_{1}\left(t\right)=\sum\limits_{i=1}^{M}\left[\left(r** t\right)-z_{e}\left({\bf{x}}_{i}\right)\cdot{\rm{log}}\left(r** t\right)\right] $$ (15) The optimization condition for Eq. 14 can be achieved by making the gradients of Eq. 15 equal to zero as

$$ \nabla L_{1}\left(t\right)=r^{\star}**\left[{\bf{1}}-\frac{z_{e}}{r** t}\right]={\bf{0}} $$ (16) where $ r^{\star}\left({\bf{x}}\right)=r\left(-{\bf{x}}\right) $ is the adjoint of $ r\left({\bf{x}}\right) $. Eq. 16 can be easily fed into a gradient-descent method with $ t^{k+1}=t^{k}+\beta\cdot\nabla L_{1}\left(t\right) $, which is similar to the additive updates introduced in FIM. Nevertheless, this method generates negative values in each iteration, which should be reset to $ t_{min} $. This deviates the iteration point from the search direction given by the gradient, and convergence is not guaranteed72. Therefore, the R-L algorithm chose to solve this problem multiplicatively. Dividing both sides of Eq. 16 by the $ {\rm{VRR}} $ of $ r\left({\bf{x}}\right) $, it becomes

$$ \frac{r^{\star}}{{\rm{VRR}}}**\frac{z_{e}}{r**t}={\bf{1}} $$ (17) with $ (r^{\star}/{\rm{VRR}})**{\bf{1}}={\bf{1}} $ (see Eq. 7), which is also the necessary step to preserve the volume of the initial dwell time, as introduced in Section 2.1. Eq. 17 results in a multiplicative solution for the dwell time28, 42 as

$$ t^{k+1}=t^{k}\cdot\left(\frac{r^{\star}}{{\rm{VRR}}}**\frac{z_{e}}{r**t}\right) $$ (18) with $ k\in\mathbb{Z} $ and $ t^{0}=z_{e} $. The merit of Eq. 18 is that the positiveness of the iterative updates is guaranteed if the initial guess $ t^{0} $ is positive, which is usually achieved by adding a constant piston term to offset $ z_{e} $.

-

As suggested in Refs. 28, 42, to further smooth the dwell time, a penalty term on the gradient of the dwell time was introduced as

$$ L_{2}\left(t\right)=\zeta\cdot\sum\limits_{i=1}^{M}\left|\nabla t\right| $$ (19) where $ \zeta $ is a weighting parameter. Adding Eq. 19 to Eq. 14 and applying the Euler-Lagrange equation28, the modified BAM iterations are deduced as

$$ t^{k+1}=\frac{t^{k}}{1-\zeta\cdot\dfrac{\Delta t^{k}}{\left|\nabla t^{k}\right|}}\cdot\left(\frac{r^{\star}}{{\rm{VRR}}}**\frac{z_{e}}{r**t}\right) $$ (20) where $ \Delta $ is the Laplace operator. However, in practice, we found that $ \zeta $ is a hyperparameter that can be difficult to adjust. As claimed in Ref. 28, a small $ \zeta $ has little effect on the smoothness, while a large $ \zeta $ reduces the accuracy of the dwell time. Additionally, we found that the positivity of the dwell time in Eq. 20 cannot be automatically maintained, and the search direction of the Bayesian function is biased, leading to a lack of guarantee of convergence.

Therefore, in this study, the original R-L algorithm given in Eq. 18 is implemented in BAM. As shown in Section 2.2.2, the Poisson distribution of the likelihood is already a reasonable and smooth assumption for most optical surfaces. We recommend that if the noise level is high, this likelihood probability distribution needs to be redesigned72 instead of adding the penalty term given in Eq. 19.

Finally, to accelerate the convergence, we introduce the over-relaxation parameter and adaptive update strategy proposed in FIM41 to BAM, as shown in Algorithm 2, which is the same as Algorithm 1 except for Lines 1 and 5. In Algorithm 2, the two convolutions in Line 5 can be accelerated by FFT. Moreover, as the adjoint operation corresponds to the complex conjugate in the frequency domain, the FFT of r can be pre-computed. Therefore, in each iteration, only two FFTs are required, which makes BAM a computationally efficient algorithm as FIM.

-

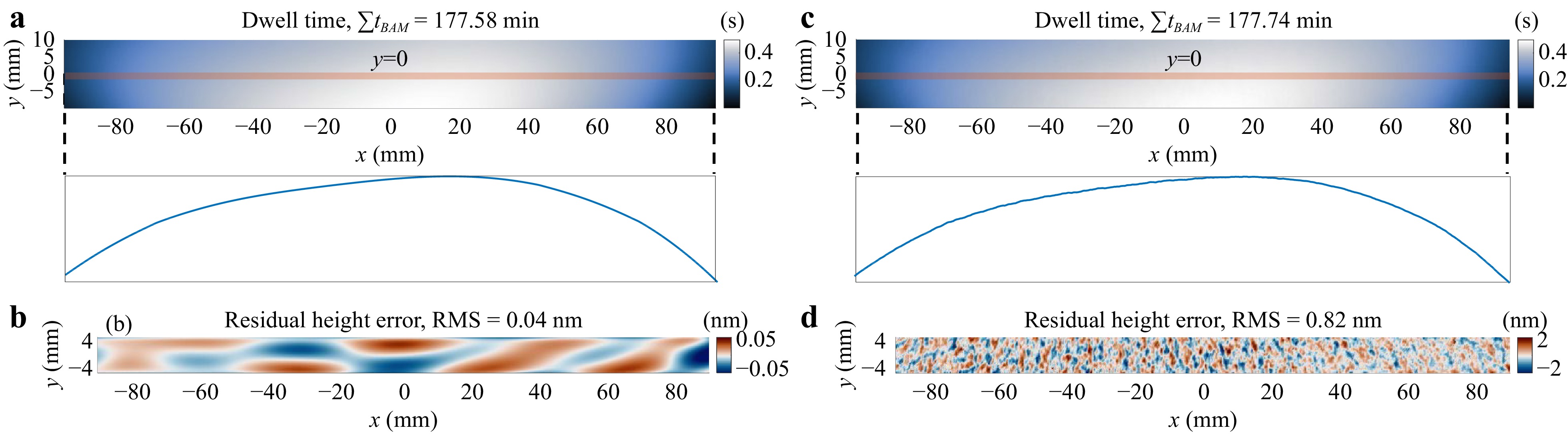

We first apply Algorithm 2 to correct the nominal target removal map without MFE and HFE as shown in Fig. 4a. The optimized dwell time and the corresponding residual height error are shown in Fig. 7a, b, respectively. The dwell time map closely duplicates the shape of the nominal removal, and the total dwell time is only 0.2% longer than the ground truth. The RMS of the residual height error is 0.04 nm, which is similar to that of FIM and can be neglected. BAM does not show an obvious advantage of FIM because it essentially does the same iterative updates as the FIM but in a multiplicative manner.

Fig. 7 Dwell time and residual height errors calculated using BAM. a, b are the dwell time and residual height errors without the middle-frequency error (MFE) and high-frequency-error (HFE), respectively. c, d are the dwell time and residual height errors with MFE and HFE, respectively. BAM handles MFE and HFE better than FIM.

We repeat the test on the nominal target removal with MFE and HFE shown in Fig. 4b. As illustrated in Fig. 7c, d, the superiority of BAM over FIM is evident in this case. The dwell time duplicates the shape of the nominal removal and is much smoother than that of FIM. The residual height error, which is 0.82 nm RMS, validates our explanation that the Poisson distribution assumption for $ P\left(z_{e}|t\right) $ is a suitable noise model, resulting in more favorable dwell time in the presence of MFE and HFE. Therefore, we encourage users to use BAM first to obtain a smooth dwell time solution and inspect the resulting residual height error. FIM can then be applied to correct this residual height error if it is still beyond the threshold $ \epsilon $, in which case the final dwell time can be obtained as $ t_{BAM}+t_{FIM} $. Although $ t_{FIM} $ may be spiky, the amplitude is small compared with that of $ t_{BAM} $, which will not significantly stress the machine dynamics in actual CCOS processes.

-

We have mentioned several critical convergence criteria for FIM and validated its convergence to the ground truth in the simulation. We now move one step further to pursue the analytical solution for FIM in the frequency domain when it converges, which leads to FTM.

Taking the Fourier transform of Eqs. 5 and 6 with $ \alpha=\beta=1 $ and using the convolution theorem, we have

$$ \begin{align} T^{0}\left({\boldsymbol{\omega}}\right)&=Z_{e}\left({\boldsymbol{\omega}}\right) \\ T^{k+1}\left({\boldsymbol{\omega}}\right)&=T^{k}+\left[Z_{e}\left({\boldsymbol{\omega}}\right)-T^{k}\left({\boldsymbol{\omega}}\right)R\left({\boldsymbol{\omega}}\right)\right] \end{align} $$ where $ T\left({\boldsymbol{\omega}}\right) $ and $ Z_{e}\left({\boldsymbol{\omega}}\right) $ are the Fourier transforms of $ t\left({\bf{x}}\right) $ and $ z_{e}\left({\bf{x}}\right) $, respectively. Successive substitution of the iterative updates results in

$$ \begin{aligned}& T^{k+1}\left({\boldsymbol{\omega}}\right)=\\&\;\;\underbrace{\left\{1 + \left[1-R\left({\boldsymbol{\omega}}\right)+\left[1-R\left({\boldsymbol{\omega}}\right)\right]\right]^{2}+\ldots+\left[1-R\left({\boldsymbol{\omega}}\right)\right]^{k}\right\}}_{ \rm{binomial\; expansion\; of }\;\left\{1-\left[1-R\left({\boldsymbol{\omega}}\right)\right]\right\}^{-1}}\cdot Z_{e}\left({\boldsymbol{\omega}}\right) \end{aligned} $$ in which the series in the curly brace is the first $ k+1 $ terms of the binomial expansion of $ \left\{1-\left[1-R\left({\boldsymbol{\omega}}\right)\right]\right\}^{-1} $. Therefore, $ T^{k+1}\left({\boldsymbol{\omega}}\right) $ converges to $ Z_{e}\left({\boldsymbol{\omega}}\right)/R\left({\boldsymbol{\omega}}\right) $, if $ \left|1-R\left({\boldsymbol{\omega}}\right)\right|<1 $64, 75, resulting in

$$ t={\cal{F}}^{-1}\left[\frac{Z_{e}\left({\boldsymbol{\omega}}\right)}{R\left({\boldsymbol{\omega}}\right)}\right] $$ (21) where $ {\cal{F}}^{-1} $ denotes inverse Fourier transform. Eq. 21 is the definition of FTM, which indicates that FIM converges to FTM when $ \left|1-R\left({\boldsymbol{\omega}}\right)\right|<1 $. Moreover, for frequencies $ {\boldsymbol{\omega}} $ at which $ R\left({\boldsymbol{\omega}}\right)=0 $, $ Z_{e}\left({\boldsymbol{\omega}}\right)=0 $ should be enforced to ensure the convergence. Hence, there is convergence from FIM to FTM if and only if

$$\left\{\begin{array}{*{20}{l}} {\left|1-R\left({\boldsymbol{\omega}}\right)\right|<1,\; }&{R\left({\boldsymbol{\omega}}\right)\neq 0}\\ {Z_{e}\left({\boldsymbol{\omega}}\right)=0,\; }&{R\left({\boldsymbol{\omega}}\right)=0} \end{array} \right. $$ These conditions are only valid when noise is absent, which cannot be achieved in actual CCOS processes. With the presence of noise, when the amplitude of $ R\left({\boldsymbol{\omega}}\right) $ at specific frequencies are close to zero, any noise in $ Z_{e}\left({\boldsymbol{\omega}}\right) $ at those frequencies will be amplified, resulting in an inaccurate dwell time solution28, 44.

To address this issue, a thresholded inverse filter $ \bar{R}\left({\boldsymbol{\omega}};\gamma\right) $ has been introduced in place of $ R\left({\boldsymbol{\omega}}\right) $ in Eq. 21, given by

$$ t={\cal{F}}^{-1}\left[\frac{Z_{e}\left({\boldsymbol{\omega}}\right)}{\bar{R}\left({\boldsymbol{\omega}};\gamma\right)}\right] $$ (22) where $ \bar{R}\left({\boldsymbol{\omega}};\gamma\right) $ is defined as

$$ \bar{R}\left({\boldsymbol{\omega}};\gamma\right)= \left\{\begin{array}{*{20}{l}} R\left({\boldsymbol{\omega}}\right),\; &\left|R\left({\boldsymbol{\omega}}\right)\right|>\gamma \\ \gamma,\; & {\rm{otherwise} } \end{array}\right. $$ The parameter $ \gamma $ is the threshold for constraining the inverse of $ R\left({\boldsymbol{\omega}}\right) $20, 38.

It is worth noting that, however, determining the optimal value for $ \gamma $ is nontrivial and depends on the noise level in the surface error map and TIF properties. Therefore, FTM is hard to apply in practice, leading to the development of RIFTA. RIFTA effectively addresses the $ \gamma $ tuning problem through an optimization approach. The optimization algorithm in RIFTA plays a crucial role in enabling FTM to function correctly. Therefore, in the subsequent sections, we focus on elaborating on the principle of RIFTA and only provide its performance evaluation.

-

The optimal threshold $ \hat{\gamma} $ in FTM is found by RIFTA through minimizing the estimated residual error in the CA, expressed as

$$ \hat{\gamma}=\underset{\gamma}{{\rm{argmin}}}\; {\rm{RMS}}\left\{z_{e}\left({\bf{x}}\right)-r\left({\bf{x}}\right)**{\cal{F}}^{-1}\left[\frac{Z_{e}\left({\boldsymbol{\omega}}\right)}{\bar{R}\left({\boldsymbol{\omega}};\gamma\right)}\right]\right\}_{CA} $$ (23) It is worth noting that Eq. 23 is non-linear and not continuous due to the thresholding operations involved in the calculation of $ \bar{R}\left({\boldsymbol{\omega}};\gamma\right) $. As a result, any derivative-based optimization algorithm will struggle to solve this optimization problem. Therefore, RIFTA utilizes derivative-free optimization methods, such as the Nelder-Mead76 or pattern search (PS) algorithm77. These methods are particularly effective when the number of variables is small and the computational complexity of the loss function is low78. Since $ \gamma $ is the only variable to be optimized and the evaluation of Eq. 23 can be accelerated by FFT, derivative-free optimization methods are thus suitable for finding $ \hat{\gamma} $.

RIFTA also innovates an iterative scheme to minimize the total dwell time. As illustrated in Figs. 3 and 4, the area $ z_{e} $ used for calculating the dwell time is larger than the required CA. To ensure that the dwell time is positive, $ z_{e} $ needs to be at least offset by a piston equal to the magnitude of its smallest entry. Nevertheless, if the smallest entry is located outside the CA, this piston adjustment may lead to an unnecessary increase in total dwell time. To address this issue, RIFTA iteratively adds pistons to $ z_{e} $ based on the previous residual errors in the CA, which can be expressed as

$$ z^{k+1}_{e}=z^{k}_{e}+\left|{\rm{min}}\left\{z^{k}_{e}-r**{\cal{F}}^{-1}\left[\frac{Z^{k}_{e}}{\bar{R}}\right]\right\}_{CA}\right| $$ (24) These iterations are performed until the RMS difference between the current and previous residual errors in the CA is less than a certain threshold or the maximum number of iterations is reached. With this iterative scheme, RIFTA ensures that $ z_{e} $ is adjusted by the smallest (i.e., optimal) piston, eliminating unnecessary dwell time increment.

-

In most CCOS processes, we are only interested in the form error correction, in which only the relatively low-frequency error (LFE) determined by the machine tool’s removal capability are corrected, with the MFE and HFE components left on the optical surface, which will then be corrected using either a smaller machine tool or a smoothing process. With the assumption of LFE correction, as shown in Fig. 2, RIFTA can be simplified by removing the thresholded inverse filtering and directly using the entire frequency components of the target removal $ z_{e} $. Therefore, in this study, we further simplify the implementation of RIFTA by approximating $ \bar{R}\left({\boldsymbol{\omega}};\gamma\right)^{-1} $ with $ \gamma $ as

$$ \begin{aligned} t\left({\bf{x}};\gamma\right)=\;&{\cal{F}}^{-1}\left[\frac{1}{\bar{R}\left({\boldsymbol{\omega}};\gamma\right)}Z_{e}\left({\boldsymbol{\omega}}\right)\right]\\\approx\;&{\cal{F}}^{-1}\left[\gamma\cdot Z_{e}\left({\boldsymbol{\omega}}\right)\right]=\gamma\cdot z_{e}\left({\bf{x}}\right) \end{aligned} $$ (25) where $ \gamma $ becomes the optimal multiplier such that

$$ \begin{align} \hat{\gamma}&=\underset{\gamma}{{\rm{argmin}}}\; {\rm{RMS}}\left[z_{e}\left({\bf{x}}\right)-r\left({\bf{x}}\right)**t\left({\bf{x}};\gamma\right)\right]_{CA}\\ &=\underset{\gamma}{{\rm{argmin}}}\; {\rm{RMS}}\left[z_{e}\left({\bf{x}}\right)-\gamma\cdot r\left({\bf{x}}\right)**z_{e}\left({\bf{x}}\right)\right]_{CA} \end{align} $$ (26) and the final dwell time is obtained as

$$ t\left({\bf{x}};\hat{\gamma}\right)=\hat{\gamma}\cdot z_{e}\left({\bf{x}}\right) $$ (27) It is worth mentioning that the dwell time obtained in Eq. 27 is equivalent to finding the optimal initial guess for FIM defined in Eq. 5 that minimizes the estimated residual error in the CA. Although the dwell time solution contains the same frequency components as the target removal, as will be shown in Section 2.3.3, this is always a suitable assumption for CCOS applications, as it guarantees that no new MFE or HFE will be introduced to the dwell time solution, thus adding implicit smoothness constraints. Combined with the total dwell time reduction scheme, the optimized implementation of RIFTA is illustrated in Algorithm 3.

As shown in Line 2, the initial guess of $ \gamma $ for the first iteration is taken as the amplitude of the direct current component of $ R\left({\boldsymbol{\omega}}\right) $, which is $ \gamma^{0}=\left|R\left({\boldsymbol{\omega}}={\bf{0}}\right)\right| $, as it is close to the optimal value66. Also, it is essential to note that $ \gamma $ is optimized in each iteration, as the target removal $ z_{e} $ is continuously adjusted to minimize the total dwell time. The iterative reduction of the dwell time is stopped when the desired residual error is attained, or the current residual error in the CA stops decreasing, indicating divergence.

-

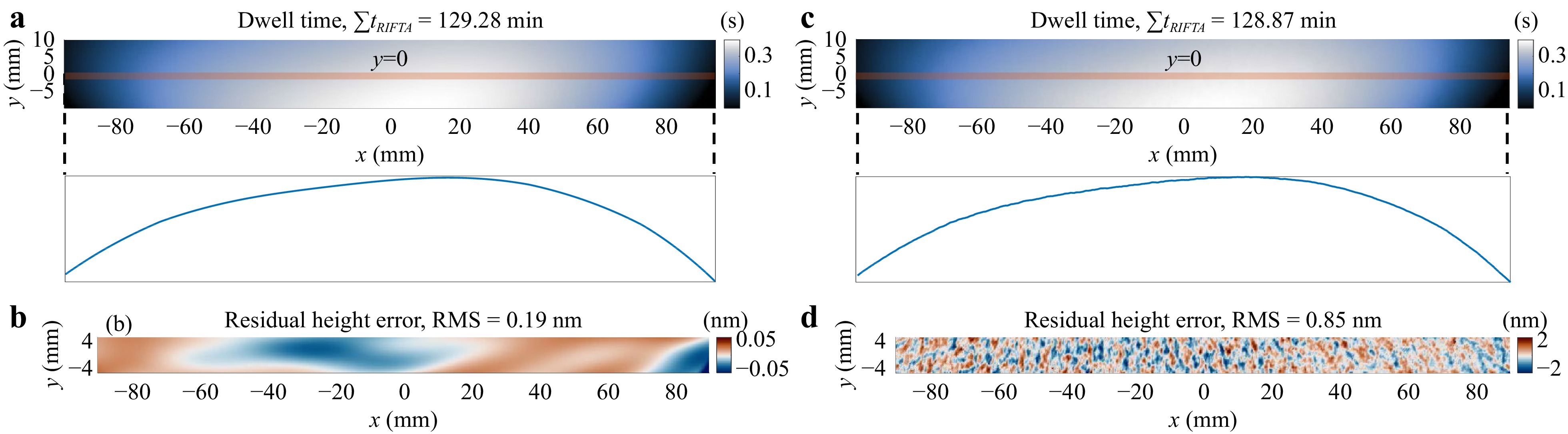

We apply RIFTA in Algorithm 3 to the nominal removal in Fig. 4a without MFE and HFE components. Fig. 8a, b show the optimized dwell time and the corresponding residual height error map, respectively. Thanks to the iterative dwell time reduction scheme with respect to the CA, RIFTA achieves a total dwell time of 129.28 min, which is about 50 min shorter than the ground truth, FIM, and BAM. This can be visually observed by the smaller dwell time entries along the edges of the dwell time map in Fig. 8a. However, the residual height error, 0.19 nm RMS, as illustrated by Fig. 8b, is slightly larger than those of FIM and BAM, indicating that RIFTA is methodologically less accurate than FIM and BAM, as it includes a more strict smoothness constraint defined in Eq. 27.

Fig. 8 Dwell time and residual height errors calculated using RIFTA. a, b are the dwell time and residual height errors without the middle-frequency error (MFE) and high-frequency-error (HFE), respectively. c, d are the dwell time and residual height errors with MFE and HFE, respectively. RIFTA not only handles MFE and HFE well, but also has shorter total dwell time than FIM and BAM.

When MFE and HFE are present, as shown in Fig. 8c, d, the two advantages of RIFTA over FIM and BAM become evident. First, RIFTA achieves a much smoother dwell time than FIM, resulting in the same residual error level as BAM. Second, this residual error is obtained with a 27% shorter total dwell time. This total dwell time reduction scheme is especially significant in large optics fabrication, where such a percentage means efficiency improvements of days or even months. Hence, we recommend always using RIFTA to solve the function-form dwell time optimization problem if there is enough measurement data outside the CA, as it handles MFE and HFE well while minimizing the total dwell time. In most cases, this RIFTA solution is satisfactory. However, if the desired residual error threshold is not achieved, FIM can be further applied to the residual error map, and the final dwell time is obtained as $ t_{RIFTA}+t_{FIM} $.

-

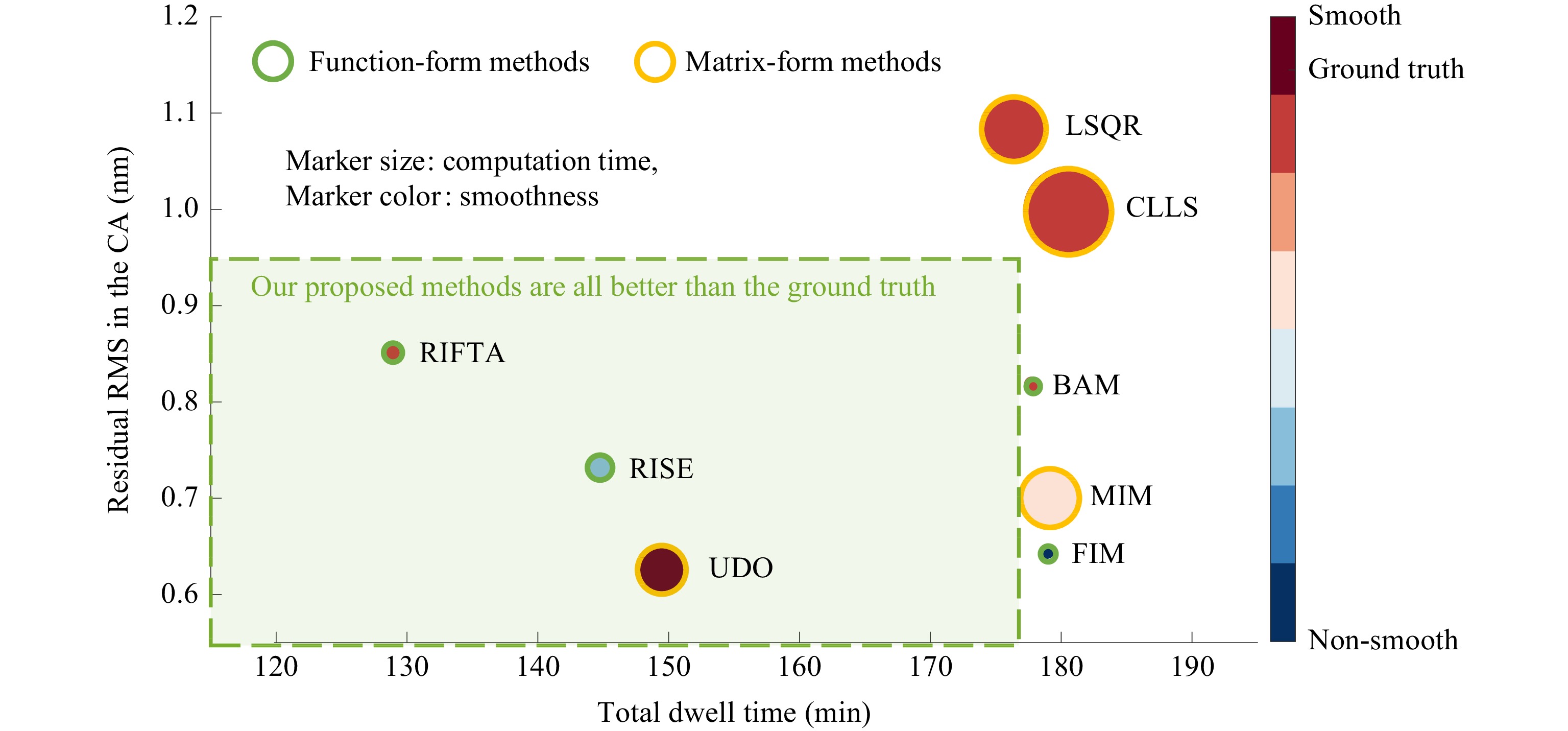

In the previous sections, we assumed that the data outside the CA is always available for optimizing the dwell time. Consequently, the dwell time solution is always satisfactory, and the residual error in the CA is small. However, there are cases when only the data inside the CA is available for dwell time optimization, which typically happens when the desired residual error is not attained after one CCOS process. For instance, Fig. 9 shows the interferometric measurement of an elliptical-cylindrical surface after one IBF process. It is evident from the reconstructed height map that the errors along the edge of $ z_{e} $ is large, which is resulted from the insufficient boundary dwell time during the dwell time optimization. Suppose the desired residual error in the CA is not achieved, and no smaller TIF is available. In that case, the dwell time solution for the next IBF run will be inaccurate since it will consume much dwell time to correct the significant boundary errors, which is unnecessary.

Fig. 9 The large edge errors in $ z_{e} $ will resulted from the last IBF process due to insufficient boundary dwell time.

To address this issue, a more proper way to calculate the dwell time is to rely on surface extrapolation to obtain the extra data in $ z_{e} $, using only the measurements within the CA. Conventional surface extrapolation methods include the Papoulis-Gerchberg extrapolation20, 70, 79, 80, nearest-neighbors extrapolation70, 81, Gaussian extrapolation70, 81, and natural neighbor extrapolation (NNE)81. A descending profile has even been proposed to reduce the extended errors along the boundary and help decrease the total dwell time81. However, despite the widespread adoption of these surface extrapolation methods in CCOS processes, two challenges remain that restrict their ability to achieve accurate dwell time solutions.

First, the measured errors in the CA are not adequately modeled so that the continuity along the extrapolation boundary is not guaranteed, especially when the error in the CA is anisotropic.

Second, MFE and HFE that a particular TIF cannot correct are also extrapolated. This improper handling of extrapolation results in unsatisfactory boundary data in $ z_{e} $ and expected errors in the unreliable dwell time solution.

Polynomial-based extension. To answer these two challenges, RISE was proposed45. Firstly, RISE models the errors in the CA using orthogonal polynomials, which eliminates the continuity issues at the boundaries of the CA. We define a boundary condition on $ z_{e} $ as its outermost perimeter, denoted as $ \partial z_{e} $. In the fitting process, besides the known error in the CA, $ \left[z_{e}\right]_{CA} $, a boundary $ \partial z_{e} $ is also included to tune the fitting coefficients and the extrapolated data. The simplest way is to set $ \partial z_{e}=0 $. However, this is so strict that it may cause significant errors in the dwell time. Instead, $ \partial z_{e} $ can be initialized as the boundary of $ \left[z_{e}\right]_{CA} $ after NNE, which is denoted by $ z_{e|NNE} $, i.e., $ \partial z_{e}=\partial z_{e|NNE} $, since NNE guarantees the $ C^{1} $ continuity along the extrapolation boundary81. Nevertheless, as NNE amplifies the errors along the CA boundary and may bring unnecessary dwell time, RISE introduces a factor $ \xi,\; \xi\in(0,1] $, which is multiplied to $ \partial z_{e|NNE} $ to flexibly adjust the figure errors in the extrapolation region and tune the dwell time. Based on the above description, the polynomial-based extension in RISE, denoted as $ z_{e|Poly}\left({\bf{x}}_i\right) $, can be summarized as the following constrained least-squares problem

$$ \begin{align} \hat{c}_{j}&=\underset{c_{j}}{{\rm{argmin}}}\sum\limits_{i}\left|z_{e|Poly}\left({\bf{x}}_i\right)-\sum\limits_{j}c_{j}Q_{j}\left({\bf{x}}_{i}\right)\right|^{2} \\ & {\rm{s.t.}}\; \; \; \; \partial z_{e}=\xi\cdot\partial z_{e|NNE} \\ &\; \; \; \; \; \; \; \; \left[z_{e|Poly}\right]_{CA}=\left[z_{e}\right]_{CA} \end{align} $$ (28) where $ c_{j} $ is the coefficient of the $ j $th polynomial $ Q_{j} $. The extrapolated surface is obtained as $ z_{e|Poly}\left({\bf{x}}_i\right)=\sum_{j}\hat{c}_{j}Q_{j} $, after which the dwell time $ t $ is optimized using RIFTA introduced in Algorithm 3.

Iterative refinement of the dwell time. Even with the proposed polynomial-based extension, the obtained dwell time may remain sub-optimal due to the possible errors introduced during the extrapolation and the unreliable, ill-posed deconvolution. Therefore, a refinement of dwell time is performed by iteratively extrapolating the residual error in the CA to approach a better dwell time solution progressively. Denoting the residual error in the CA in the $ (k+1) $th $ (k\geq0) $ iteration as $ e_{CA}^{k+1}=z_{e}-\left[r**t\right]^{k} $, the polynomial extension is applied to $ e_{CA}^{k+1} $ to obtain $ z_{e|Poly}^{k+1} $. The resulting incremental dwell time $ \Delta t $ obtained using RIFTA is then added to the updated dwell time solution $ t^{k+1} $ as

$$ t^{k+1}=t^{k}+h\cdot\Delta t $$ (29) where $ h $ is the learning rate that controls the convergence speed. Additionally, to eliminate the unnecessary dwell time added in $ \Delta t $ in each iteration, an intelligent piston adjustment45 is performed on $ z_{e|Poly}^{k+1} $ and only the resulted $ \Delta z_{e|Poly}^{k+1} $ is used with RIFTA to obtain $ \Delta t $ and updates $ t^{k+1} $ as

$$ t^{k+1}=t^{k}+h\cdot{\rm{RIFTA}}\left(\Delta z_{e|Poly}^{k+1},r,\epsilon,N\right) $$ (30) where

$$ \Delta z_{e|Poly}^{k+1}=z_{e|Poly}^{k+1}-{\rm{min}}\left(z_{e|Poly}^{k+1}+z_{e|Poly}^{k}\right) $$ (31) This piston adjustment eliminates the extra removal added during each iteration and hence relaxes the positivity requirement of $ \Delta t $ but only guarantees the final $ t^{k+1} $ to be positive.

-

Algorithm 4 illustrates the implementation of RISE based on RIFTA (see Algorithm 3) and the iterative polynomial-based surface extrapolation. In this study, the polynomial order M is selected as 144, the same as the generated ground-truth dwell time shown in Fig. 3a for comparison among different methods. In practice, the residual error between $ \left[z_{e}\right]_{CA} $ and $ \left[z_{e|Poly}^{0}\right]_{CA} $ can guide the selection of appropriate polynomial orders45. One candidate threshold for the RMS of the residual error can be selected as the random errors of the measurement instruments employed in the CCOS process. Additionally, the learning rate $ h=0.5 \sim 0.8 $ is a proper range that allows RISE to converge in less than ten iterations45, and in this study, $ h=0.5 $ is used, as shown in Line 2. Finally, the multiplier $ \xi $ is set to 1 for the boundary condition defined in Eq. 28, as we prioritize accuracy in the comparison.

-

Fig. 10a, b demonstrate the dwell time and estimated residual error after applying Algorithm 4 to the nominal removal in Fig. 4a without MFE and HFE, respectively. While RISE achieves the same residual error level in the CA as RIFTA, the edge errors are more prominent than RIFTA, and a longer total dwell time is required, resulting from the iterative, polynomial-based extension strategy.

Fig. 10 Dwell time and residual height errors calculated using RISE. a, b are the dwell time and residual height errors without the middle-frequency error (MFE) and high-frequency-error (HFE), respectively. c, d are the dwell time and residual height errors with MFE and HFE, respectively. RISE has larger edge residual errors and longer total dwell time than those of RIFTA, but it only uses the measurements in the clear aperture.

We then test the nominal removal with the addition of MFE and HFE given in Fig. 4b. The results are given in Fig. 10c, d, respectively. While the obtained total dwell time is similar to that of the MFE-HFE-free case and a lower residual error RMS is attained compared to RIFTA, the smoothness of the dwell time is degraded in RISE, which exposes another effect of the polynomial-based extension in RISE, that the smoothness of the dwell time may be affected if the polynomial orders are not well selected.

To obtain smoother dwell time solutions, smaller numbers of polynomial orders can be attempted using the thresholding method introduced in Section 2.3.1. Also, to reduce the total dwell time, a smaller $ \xi $ can be employed in restricting the amplitude of the boundary conditions. Since RISE adopts RIFTA, a very computationally efficient method, multiple trials with different values of the polynomial orders and $ \xi $ can be conducted to balance the total dwell time and the residual error in the CA.

-

We have introduced four function-form methods in this section. As shown in Fig. 2, FIM applies the additive Van Cittert’s iterations to converge to the optimal dwell time solution progressively. Similarly, BAM uses the multiplicative, R-L algorithm to obtain a smooth dwell time solution with the assumption of a Poisson distribution of the noise model. While FIM pursues absolute convergence, BAM minimizes the relative difference between consecutive iterations. With the absence of noise, FIM converges to FTM. However, to handle the noisy CCOS processes, a threshold is required to restrict the noisy frequencies in FTM, leading to the development of RIFTA, which finds the optimal threshold for FTM while minimizing the total dwell time through an iterative piston adjustment scheme. RIFTA, if we assume that only low-frequency components are corrected in a CCOS process, is equivalent to finding the best initial guess for FIM, which further simplifies RIFTA. RISE improves upon RIFTA by using a polynomial-based surface extrapolation method to optimize dwell time when only data in the CA is available and iteratively refine the dwell time solution. RIFTA and RISE achieve comparable accuracy and smoothness to the state-of-the-art methods with significantly reduced total dwell time. Therefore, we recommend the users use RIFTA and RISE in function-form dwell time optimization problems for CCOS processes.

-

This section will discuss the matrix-form methods for dwell time optimization in depth. These methods are based on the linear system given in Eq. 4. The main challenge with this method is that the matrix $ {\bf{R}} $ is always near singular, making it hard to obtain a stable solution. The most important merit of the matrix-form method is that it enables arbitrary dwell positions, meaning that the dwell points $ {\bf{u}}_i $ and surface points $ {\bf{x}}_j $ can be different, i.e., $ {\bf{u}}_i\neq {\bf{x}}_j $ in Eq. 3. This adds flexibility when more complex tool paths are needed to restrain MFE34 or fabricate free-form optics. In this section, we will review the matrix-form dwell time optimization methods that can obtain reasonable dwell time solutions.

-

Analogous to Eq. 6, Van Cittert’s iterations can be performed in discrete matrix form49, 66 as

$$ {\bf{t}}^{k+1}={\bf{t}}^{k}+\beta\left({\bf{z}}_{e}-{\bf{R}}{\bf{t}}^{k}\right) $$ (32) In fact, FIM is a special case of MIM, in which $ {\bf{R}} $ is a square matrix. The NC1, given in Eq. 10, can be represented in matrix form66 as

$$ \left[{\bf{R}}\right]_{ii}\gg\sum\limits_{j\neq i}\left[{\bf{R}}\right]_{ij} $$ (33) Like FIM,when NC1 and NC2 hold, there is a convergence criterion in MIM related to the learning rate $ \beta $ determined from the matrix $ {\bf{R}} $. First, it has been found that if $ {\bf{R}} $ is a positive definite matrix, the convergence interval for $ {\bf{R}} $ is

$$ 0<\beta<\frac{2}{\lambda_{{\bf{R}}}^{max}} $$ where $ \lambda_{{\bf{R}}}^{max} $ is the largest eigenvalue of $ {\bf{R}} $66. However, as $ {\bf{R}} $ is always near singular, we need to multiply $ {\bf{R}} $ by its transpose, and hence $ {\bf{R}}^{{\rm{T}}}{\bf{R}} $ becomes positive definite. By multiplying the two sides of Eq. 3 with $ {\bf{R}}^{{\rm{T}}} $, we obtain

$$ {\bf{R}}^{{\rm{T}}}{\bf{z}}_{e}={\bf{R}}^{{\rm{T}}}{\bf{R}}{\bf{t}} $$ for which the iterative form of Eq. 32 becomes

$$ {\bf{t}}^{k+1}={\bf{t}}^{k}+\beta\left( {\bf{R}}^{{\rm{T}}}{\bf{z}}_{e}- {\bf{R}}^{{\rm{T}}}{\bf{R}}{\bf{t}}^{k}\right) $$ (34) Therefore, the range of $ \beta $ can be determined by finding the maximum eigenvalue $ \lambda_{{\bf{R}}^{{\rm{T}}}{\bf{R}}}^{max} $ of $ {\bf{R}}^{{\rm{T}}}{\bf{R}} $. Indeed, an estimate of the maximum eigenvalue is sufficient for MIM. As illustrated in Ref. 35, the estimated range for $\, \beta $ is approximated as

$$ 0<\beta\leq\lambda_{{\bf{R}}^{{\rm{T}}}{\bf{R}}}^{max}\leq\frac{2}{\sum_{m}^{M}\left|\left[{\bf{R}}^{{\rm{T}}}{\bf{R}}\right]_{im}\right|} $$ (35) It is worth mentioning that multiplying by $ {\bf{R}}^{{\rm{T}}} $ not only simplifies the determination of the learning rate but also brings two benefits. First, it enables MIM to be used even when the dwell points $ {\bf{u}}_{i} $ and surface points $ {\bf{x}}_{j} $ are with different sampling positions. The operation of $ {\bf{R}}^{{\rm{T}}}{\bf{z}}_{e} $ projects $ {\bf{z}}_{e} $ to the same space as $ {\bf{t}} $. More importantly, multiplying by $ {\bf{R}}^{{\rm{T}}} $ acts as a low-pass pre-filtering process. In each iteration, $ t^{k+1} $ is updated by the filtered residual, $ {\bf{R}}^{{\rm{T}}}\left({\bf{z}}_{e}-{\bf{R}}{\bf{t}}^{k}\right) $. As demonstrated in Section 3.1.2, this pre-filtering operation helps smooth the dwell time solution.

-

Algorithm 5 shows the implementation of MIM, which is very similar to that of FIM. Both methods can use the adaptive learning rate41 and early stop strategies. The maximum value in Eq. 35 initializes the learning rate $ \,\beta $ in Line 2. If the iteration becomes divergent, $\, \beta $ will be reduced in Line 16 and the iteration is retried. The initial guess for the dwell time in MIM, as shown in Line 3, is given as

$$ {\bf{t}}^{0}=\alpha\cdot{\bf{R}}^{{\rm{T}}}{\bf{z}}_{e} $$ (36) where $ \alpha=1/{\rm{VRR}} $. It is worth noting that the most time- and memory-consuming operation in Algorithm 5 is the construction of the convolution matrix $ {\bf{R}} $ when the size of the optical surface is large, and the dwell points are dense. However, since $ {\bf{R}} $ is sparse, with all non-zero elements concentrating along its diagonals, storing $ {\bf{R}} $ using sparse matrix structures, such as compressed-row or compressed-column format is always recommended. The subsequent operations on $ {\bf{R}} $ involve sparse matrix arithmetic, which have been well accelerated by math libraries on modern computing hardware.

-

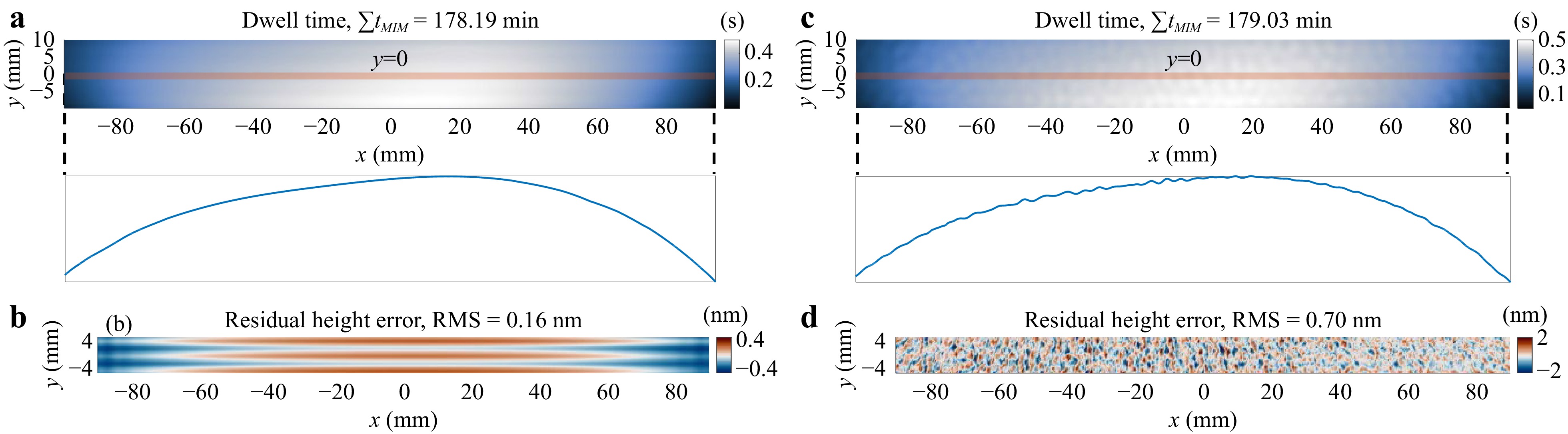

We applied MIM on the simulation data given in Fig. 4, and the results are shown in Fig. 11. In the case without MFE and HFE shown in Fig. 11a, b, compared to FIM, the total dwell time is about 1-min longer while the residual height error RMS is slightly larger. This negligible reduction in accuracy resulted from the introduction of $ {\bf{R}}^{{\rm{T}}} $ for pre-filtering.

Fig. 11 Dwell time and residual height errors calculated using MIM. a, b are the dwell time and residual height errors without the middle-frequency error (MFE) and high-frequency-error (HFE), respectively. c, d are the dwell time and residual height errors with MFE and HFE, respectively. It is evident that prefiltering with $ {\bf{R}}^{{\rm{T}}} $ smooths the dwell time.

On the other hand, in the case of MFE and HFE shown in Fig. 4c, d, the merit of multiplying with $ {\bf{R}}^{{\rm{T}}} $ is evident. With a slight degradation of algorithmic accuracy, the dwell time profile is much smoother than that obtained from FIM shown in Fig. 6c, indicating that the dwell time optimization is unaffected by MFE and HFE in MIM. Therefore, we recommend that users always use MIM with $ {\bf{R}}^{{\rm{T}}} $ pre-filtering to obtain more reliable dwell time solutions.

Moreover, as FIM is a special case of MIM, this pre-filtering idea in MIM can also be introduced to FIM as

$$ t^{k+1}({\bf{x}})=t^{k}({\bf{x}})+\beta\cdot r^{\star}({\bf{x}})**\left[z_{e}({\bf{x}})-r({\bf{x}})**t^{k}({\bf{x}})\right] $$ if the smoothness of the dwell time solution optimized with the conventional FIM is unsatisfactory and the small influence on the residual error is acceptable.

-

Instead of solving the matrix-form equation (see Eq. 4) iteratively using MIM, it can also be solved directly with the least-squares method. However, as the least-squares solution to Eq. 4 is known to be unstable, the Tikhonov regularization has been introduced to obtain a reasonable dwell time solution. With the Tikhonov regularization, the solution to Eq. 4 can be obtained by optimizing the following equation57

$$ \left|\left[\begin{array}{c} {\bf{R}}\\ \rho{\bf{I}} \end{array}\right]{\bf{t}}-\left[\begin{array}{c} {\bf{z}}_{e}\\ {\bf{0}} \end{array}\right]\right|_{2}=\sqrt{\left|{\bf{R}}{\bf{t}}-{\bf{z}}_{e}\right|^{2}_{2}+\rho^{2}\left|{\bf{t}}\right|^{2}_{2}} $$ (37) where $ \rho $ is a damping factor that penalizes the magnitude of the solution vector. This section will demonstrate how Tikhonov regularization helps stabilize the solution and improve the overall performance.

-

The Tikhonov-regularized solution to Eq. 37 is equivalent to finding the particular least-squares solution, which is the minimum in the $ l_{1} $-norm sense57 expressed as

$$ \left|{\bf{t}}\right|_{1}=\left|t_{0}\right|+\left|t_{1}\right|+\ldots+\left|t_{M-1}\right| $$ (38) SVD can be used to find the solution of $ {\bf{t}} $ in this sense as

$$ {\bf{t}}=\sum\limits_{i=0}^{M-1}\frac{{\bf{u}}_{i}^{{\rm{T}}}{\bf{z}}_{e}}{\sigma_{i}}{\bf{v}}_{i} $$ (39) where $ \sigma_{i} $, $ i=0,1,2,\ldots,M-1 $, are the singular values appearing in non-increasing order; $ {\bf{u}}_i $ and $ {\bf{v}}_i $ are the left and right singular vectors of $ {\bf{R}} $, respectively. As many of the singular values are close to zero since $ {\bf{R}} $ is nearly singular, TSVD should be used instead of SVD54, in which only the first $ K $ singular values are kept as

$$ {\bf{t}}=\sum\limits_{i=0}^{K-1}\frac{{\bf{u}}_{i}^{{\rm{T}}}{\bf{z}}_{e}}{\sigma_{i}}{\bf{v}}_{i},\; K\leq M $$ (40) There are two difficulties in solving for $ {\bf{t}} $ directly using Eq. 40 in practice. First, the total dwell time is not guaranteed to be minimal, even though $ |{\bf{t}}|_{1} $ is minimized, since the positivity of $ {\bf{t}} $ cannot be ensured in Eq. 40. To mitigate the negative entries in $ {\bf{t}} $, multiple trials of extra piston adjustments of $ {\bf{z}}_{e} $ are necessary. Additionally, determining the optimal number of singular values $ K $ is difficult. While the “L” curve approach has been attempted54, in which $ K $ at the turning point on the curve was selected, the computation of SVD is extremely time-consuming, making it impractical to generate sufficient data points for plotting the “L” curve.

-

To address the two difficulties associated with TSVD, an efficient iterative solver names LSQR82 has been proposed, taking advantage of the sparse nature of $ {\bf{R}} $. Instead of directly calculating all the singular values, the LSQR algorithm employs iterative steps to refine the dwell time solution. It gradually converges to a solution that balances the minimization of the residual error and the regularization imposed by TSVD16, 29, 30, 50-52, 56, 57. The final solution to Eq. 37 is closely related to the minimum $ l_{1} $-norm solution given by Eq. 39 as

$$ {\bf{t}}=\sum\limits_{i=0}^{M-1}\frac{\sigma_{i}{\bf{u}}_{i}^{{\rm{T}}}{\bf{z}}_{e}}{\sigma_{i}^{2}+\rho^{2}}{\bf{v}}_{i} $$ (41) When $ \rho=0 $, Eq. 41 is equivalent to Eq. 39. The $ \rho^{2} $ term in the denominator “damped” the least-squares solution by preventing small values of $ \sigma_{i} $ from causing the solution $ {\bf{t}} $ to grow excessively large. The parameter $ \rho $ plays a crucial role in balancing the smoothness, accuracy, and distribution of negative entries in $ {\bf{t}} $53. The choice of $\, \rho $ impacts the characteristics of the solution. Larger values of $\, \rho $ tend to result in a smoother dwell time profile with fewer negative entries, but at the cost of reduced accuracy. Conversely, smaller values of $ \,\rho $ can lead to increased accuracy but may result in a less smooth dwell time profile and potentially more negative entries in $ {\bf{t}} $53, 57.

Therefore, finding an appropriate value for $ \rho $ is a trade-off between achieving the desired level of smoothness, accuracy and minimizing negative entries in $ {\bf{t}} $. Traditionally, the selection of a proper damping factor $ \rho $ has been based on trial-and-error53, 57 or the “L” curve obtained by time-consuming exhaustive search54, which can be time-consuming. Researchers have also explored finding a typical range for $ \rho $ based on the PRR of a TIF, which provides some guidance for choosing $ \rho $52. However, this range is unstable when the desired residual error is small. Due to the sensitivity of the damping factor, it is essential to carefully and automatically evaluate and choose the optimal $ \rho $ based on specific criteria. The derivative-free optimization method used in RIFTA and RISE reviewed above can be employed to automate the determination of the optimal $ \rho $ in this problem58, which will be detailed in the following section.

-

The optimized implementation of LSQR is shown in Algorithm 6, which automates the damping factor tuning while maintaining the positiveness of the dwell time solution58.

The automatic $ \rho $ optimization algorithm uses the merit criterion of the residual error RMS, as indicated in Lines 6 − 8. The positivity in the evaluation of $ {\bf{t}} $ is ensured through Line 11, where $ {\bf{t}} $ is adjusted such that its smallest value $ {\rm{min}}({\bf{t}}) $. Calculating the derivatives of the merit function is challenging, making it necessary to employ derivative-free optimization methods as introduced in Section 2.3.1 are used. The PS optimization method58, 77 is selected in this study, as shown in Line 3. It is worth mentioning that the iterative Least-squares with MR factorization (LSMR) solver is utilized to calculate $ {\bf{t}} $ instead of LSQR, as shown in Line 10 because it converges faster for incompatible linear systems (i.e., the dwell points are less than the sampling points of a measured workpiece surface) and is more computationally efficient58, 83.

For PS to converge faster, a suitable initial guess for $ \,\rho $, denoted as $ \,\rho_{ini} $, is required. While $\, \rho_{ini} $ can be selected as a value suggested in Ref. 29 or randomly picked from the typical range52, it has been observed that these values may not be appropriate for the positiveness adjustment. Instead, as depicted in Line 2, a more reliable derivative-free optimization method, Particle Swarm Optimization (PSO), is utilized to generate a well-suited $\, \rho_{ini} $, eliminating the need for manually determining an initial guess58. To mitigate the computational burden of PSO, the algorithm is stopped early when it stalls at a merit function value. Ultimately, the calculation of $ {\bf{t}} $ involves utilizing the optimized damping factor $ \hat{\rho} $ obtained from PS in Line 4.

-

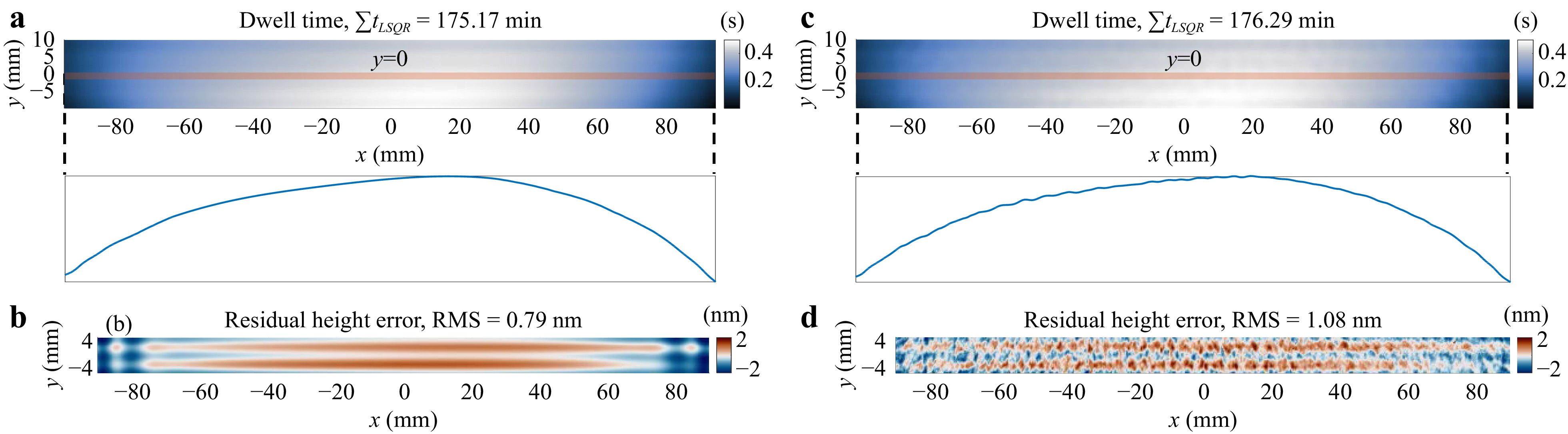

We apply Algorithm 6 to optimize dwell time for the nominal removal maps with and without MFE and HFE. The results are presented in Fig. 12. As shown in Fig. 12a, c, both dwell time maps closely resemble the ground truth, and the smoothness of the dwell time profile is not affected much by MFE and HFE thanks to the damping factor optimization method.

Fig. 12 Dwell time and residual height errors calculated using LSQR. a, b are the dwell time and residual height errors without the middle-frequency error (MFE) and high-frequency-error (HFE), respectively. c, d are the dwell time and residual height errors with MFE and HFE, respectively.

However, as depicted in Fig. 12b, d, the accuracy of LSQR is lower than those obtained from MIM. Notably, both residual error maps exhibit LFE components that could have been corrected, indicating that more iterations may be required for LSQR to achieve the same level of accuracy as MIM. Thus, we recommend that users relax the constraint of the maximum number of iterations and mainly rely on the residual error RMS to stop the LSQR method.

-

In the Tikhonov-regularized method, the damping factor is added to penalize the significant variations in the dwell time solution, improving the smoothness and reducing the number of negative entries57. Alternatively, these objectives can be achieved by solving Eq. 4 with the CLLS algorithm30, 60, 59, 84, which incorporates appropriate constraints to limit the search space of the dwell time solution. The CLLS problem can be formulated as

$$ \begin{align} \hat{{\bf{t}}}&=\underset{{\bf{t}}}{{\rm{argmin}}}\frac{1}{2}\left|{\bf{z}}_{e}-{\bf{R}}{\bf{t}}\right|^{2}_{2} \\ {\rm{s.t.}}\; \; \; \; & t_{min}\leq {\bf{t}}\leq t_{max} \\ \; \; \; \; \; \; \; \; &{\bf{A}}{\bf{t}}\leq{\bf{b}} \end{align} $$ (42) where $ t_{min}\leq {\bf{t}}\leq t_{max} $ is the bounding constraints that ensure the positivity of $ {\bf{t}} $59 and can be tuned based on the constraints of the machine dynamics30; $ {\bf{A}} $ is the adjacency matrix of $ {\bf{t}} $ and $ {\bf{b}} $ is the upper limit of the absolute difference between every two adjacent elements in $ {\bf{t}} $59, 84. Therefore, the inequality constraints can impose smoothness constraints on the dwell time solution. To solve Eq. 42, it can be reformulated as a general quadratic programming problem by letting $ {\bf{H}}={\bf{R}}^{{\rm{T}}}{\bf{R}} $ and $ {\bf{q}}=-{\bf{R}}^{{\rm{T}}}{\bf{z}}_e $, resulting in

$$ \begin{align} \hat{{\bf{t}}}&=\underset{{\bf{t}}}{{\rm{argmin}}}\frac{1}{2}{\bf{t}}^{{\rm{T}}}{\bf{H}}{\bf{t}}+{\bf{q}}^{{\rm{T}}}{\bf{t}} \\ {\rm{s.t.}}\; \; \; \; &t_{min}\leq {\bf{t}}\leq t_{max} \\ \; \; \; \; \; \; \; \; &{\bf{A}}{\bf{t}}\leq{\bf{b}} \end{align} $$ (43) and any quadratic programming method (e.g., the active-set method in Ref. 59) can be employed to solve this problem.

-

It can be observed from Eq. 42 that setting proper values for the dwell time difference constraints in the vector $ {\bf{b}} $ is a non-trivial task. Direct utilization of the CLLS algorithm may lead to inaccurate dwell time solutions, especially when the constraints in $ {\bf{b}} $ are too strict while the local shape changes in the target removal $ {\bf{z}}_e $ are large. To answer this challenge, the optimized implementation of CLLS, employing the coarse-to-file scheme59, is presented in Algorithm 7.

On the coarse level, as shown in Lines 3 and 4, the inequality constraints in Eq. 42 are disabled, and an initial dwell time solution $ {\bf{t}}_{ini} $ is calculated as

$$ \begin{align} {\bf{t}}_{ini}&=\underset{{\bf{t}}}{{\rm{argmin}}}\frac{1}{2}{\bf{t}}^{{\rm{T}}}{\bf{H}}{\bf{t}}+{\bf{q}}^{{\rm{T}}}{\bf{t}} \\ {\rm{s.t.}}\; \; \; \; &t_{min}\leq {\bf{t}}\leq t_{max} \\ \end{align} $$ (44) which is not always smooth enough. Therefore, a polynomial fitting is performed on $ {\bf{t}}_{ini} $ to smooth it and obtain a new dwell time solution $ {\bf{t}}_{coarse} $. Subsequently, $ {\bf{t}}_{coarse} $ is utilized to calculate the residual at the coarse level, denoted as $ {\bf{e}}_{coarse} $.

On the fine level, as shown in Lines 5 and 6, the residual $ {\bf{e}}_{fine}={\bf{z}}_{e}-{\bf{e}}_{coarse} $ is substituted to Eq. 42 to calculate the dwell time $ {\bf{t}}_{fine} $. Since the residual error $ {\bf{e}}_{fine} $ is small, the necessary difference constraints in b are small and relatively easier to set. The final dwell time is calculated as $ {\bf{t}}={\bf{t}}_{coarse} + {\bf{t}}_{fine} $. As both $ {\bf{t}}_{coarse} $ and $ {\bf{t}}_{fine} $ are smooth, $ {\bf{t}} $ is thus smooth. This optimized CLLS implementation allows for a more accurate and smooth dwell time solution by refining the solution at different levels of detail.

-

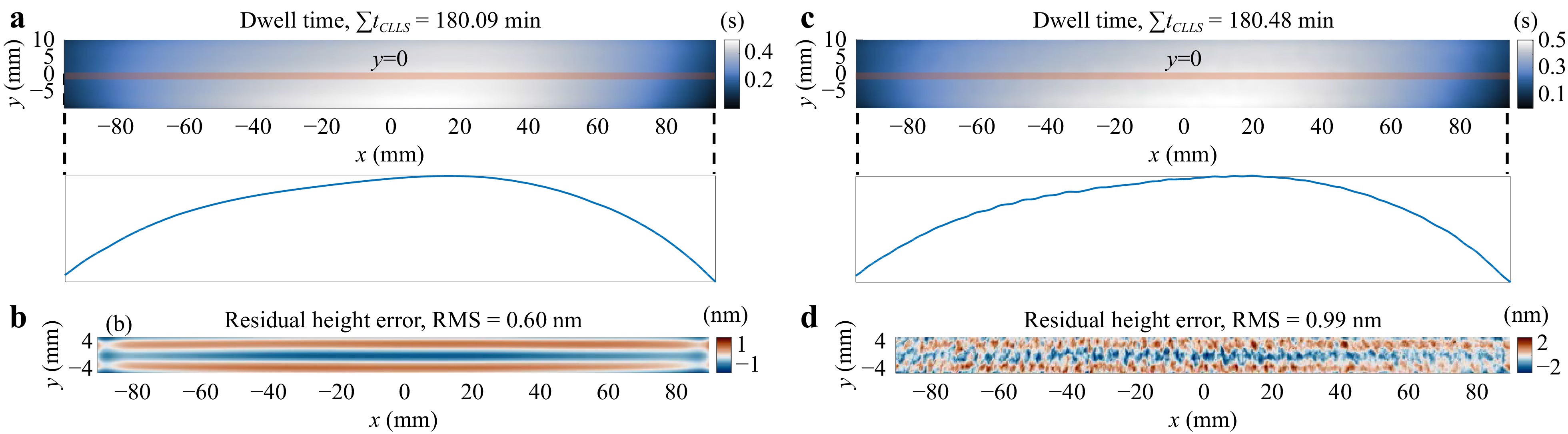

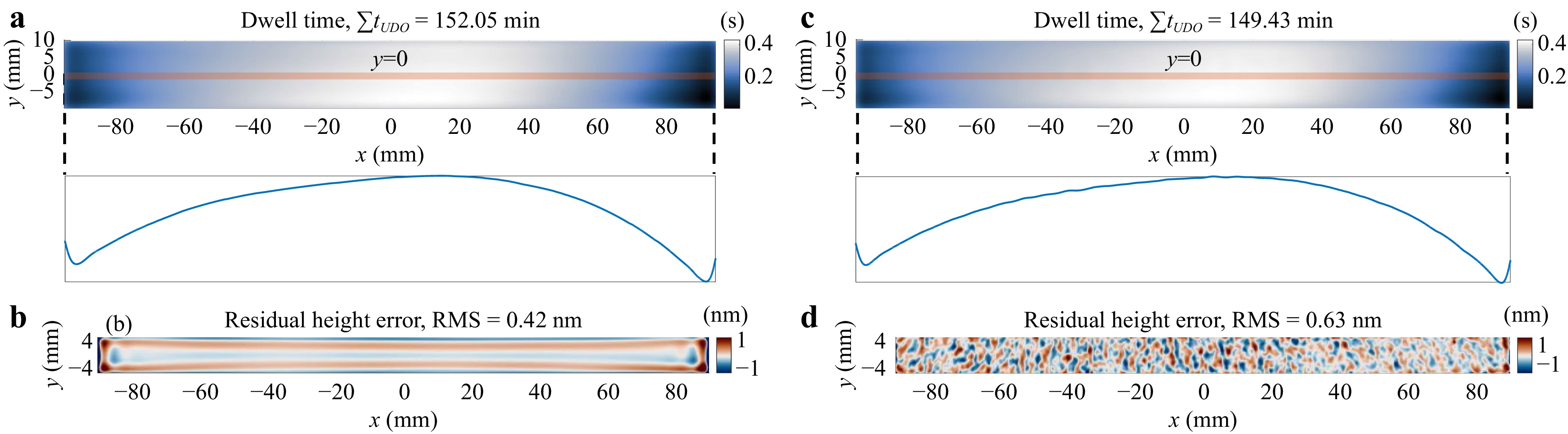

The implementation of CLLS introduced in Algorithm 7 is tested on the nominal removal maps shown in Fig. 4, and the results are demonstrated in Fig. 13. As we know the ground truth, the maximum absolute dwell time difference between adjacent dwell time entries in $ t_{GT} $ shown in Fig. 3a, which is 1.3 ms, is used as the constraint in $ {\bf{b}} $. Additionally, $ t_{max}=+\infty $ is set as the upper bound constraint.