-

As deep-space exploration enters a new era, the requirements for the service life and performance of detectors on spacecraft are becoming more stringent1,2. In the space environment, various types of ionising radiation can damage the detectors on the spacecraft3. Furthermore, in the nuclear industry and the field of nuclear medicine, similar radiation damage could cause health problems for personnel, including dizziness, fatigue, loss of appetite, hair loss, and other adverse reactions4-6. An urgent need to alleviate these radiation risks has therefore arisen.

The key approach to mitigating radiation risks is to shorten the exposure time to the radiation source, increase the distance from the radiation source, and use shielding materials7. Among these, the application of shielding materials is the most effective method. Short-wavelength X-rays and γ-rays are typical forms of high-energy ionising radiation with strong penetration ability8. The most commonly used X/γ-ray shielding materials are those with high atomic numbers (Z), such as lead, tungsten, tantalum, and concrete, but their high density hinders their commercial application9,10. Hence, it is necessary to develop alternative lightweight materials with excellent radiation shielding performance.

Certain polymers and their composites have been shown to be promising alternatives to lead and concrete as radiation shielding materials because they are lightweight and flexible with excellent physical, mechanical, and radiation resistance properties11,12. In the past few years, several studies have concluded that fillers in composites play a crucial role in their radiation shielding performance13-15. El-Khatib et al. studied the effects of the size of CdO particles on the gamma-ray shielding performance of CdO/HDPE, showing that the collision between gamma rays and CdO particles is dependent on the particle sizes16. This suggests that the development and design of novel fillers would be an effective strategy for improving the radiation shielding performance.

Organic-inorganic hybrid perovskites have been widely used in photoelectric devices and radiation detectors owing to their high absorption coefficient, long carrier diffusion length, low cost, lightness, and flexibility17-20. Chen et al. prepared a series of unique inorganic perovskite nanocrystals composed of caesium and lead and found that the scintillator characteristics of these perovskites facilitate their interaction with high-energy photons (i.e. X-rays and γ-rays)21. Therefore, organic-inorganic hybrid perovskites have potential as fillers in radiation-shielding materials. However, to the best of our knowledge, the fabrication of perovskite/polymer composites for radiation shielding has not been reported previously.

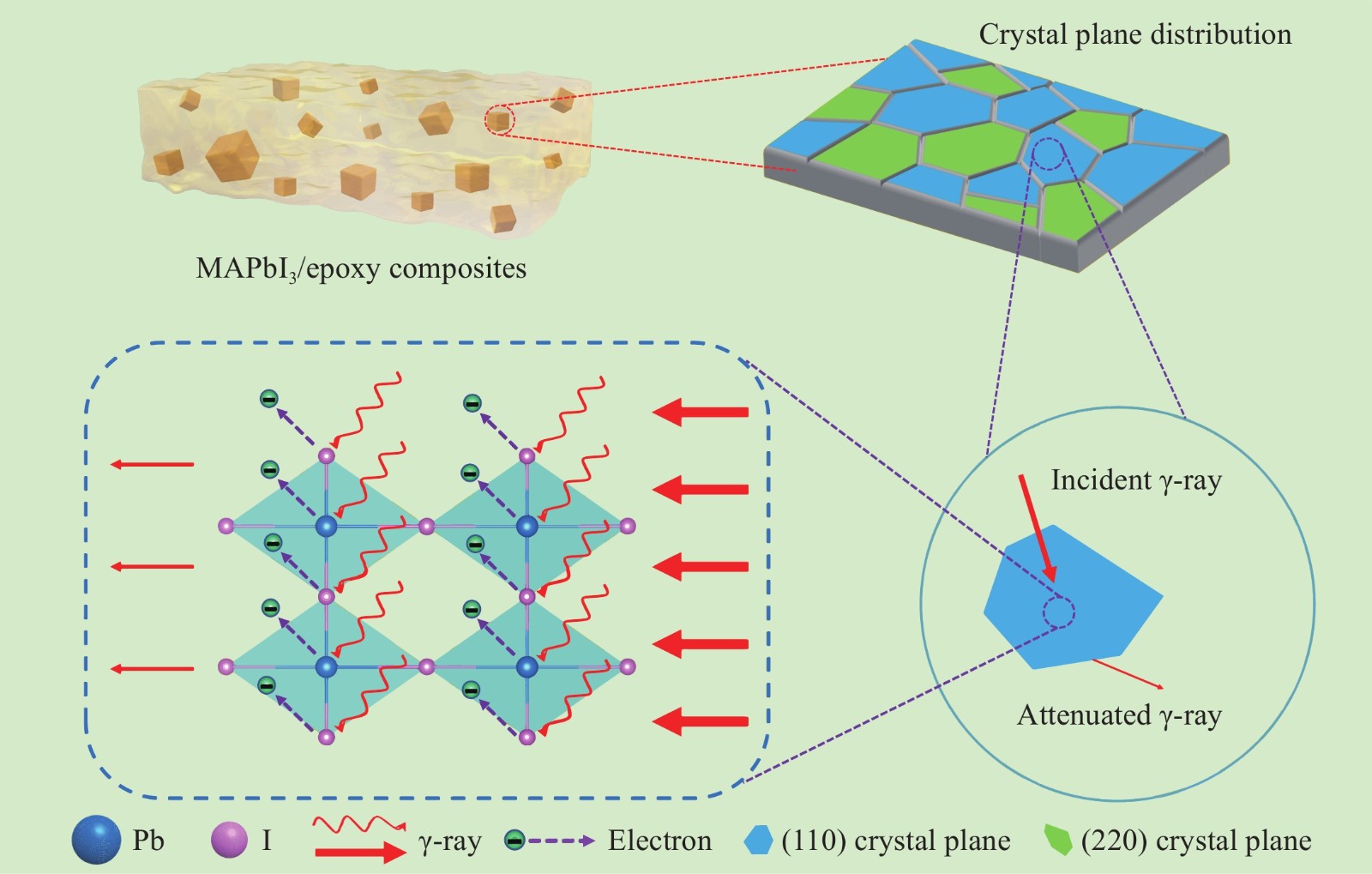

In this work, we prepared MAPbI3 microcubic crystals by a simple solvothermal method and then fabricated MAPbI3/epoxy composites. The gamma-ray shielding performance of MAPbI3/epoxy composites was evaluated using an Am-241 source. The results showed that MAPbI3 with altered crystal planes plays a determining role in the gamma-ray shielding performance of the corresponding composites. The best linear and mass attenuation coefficients obtained for the MAPbI3/epoxy composite were 1.887 cm−1 and 1.352 cm2 g−1, respectively. The present work provides essential guidelines for the design and synthesis of high-efficiency radiation-shielding composites.

-

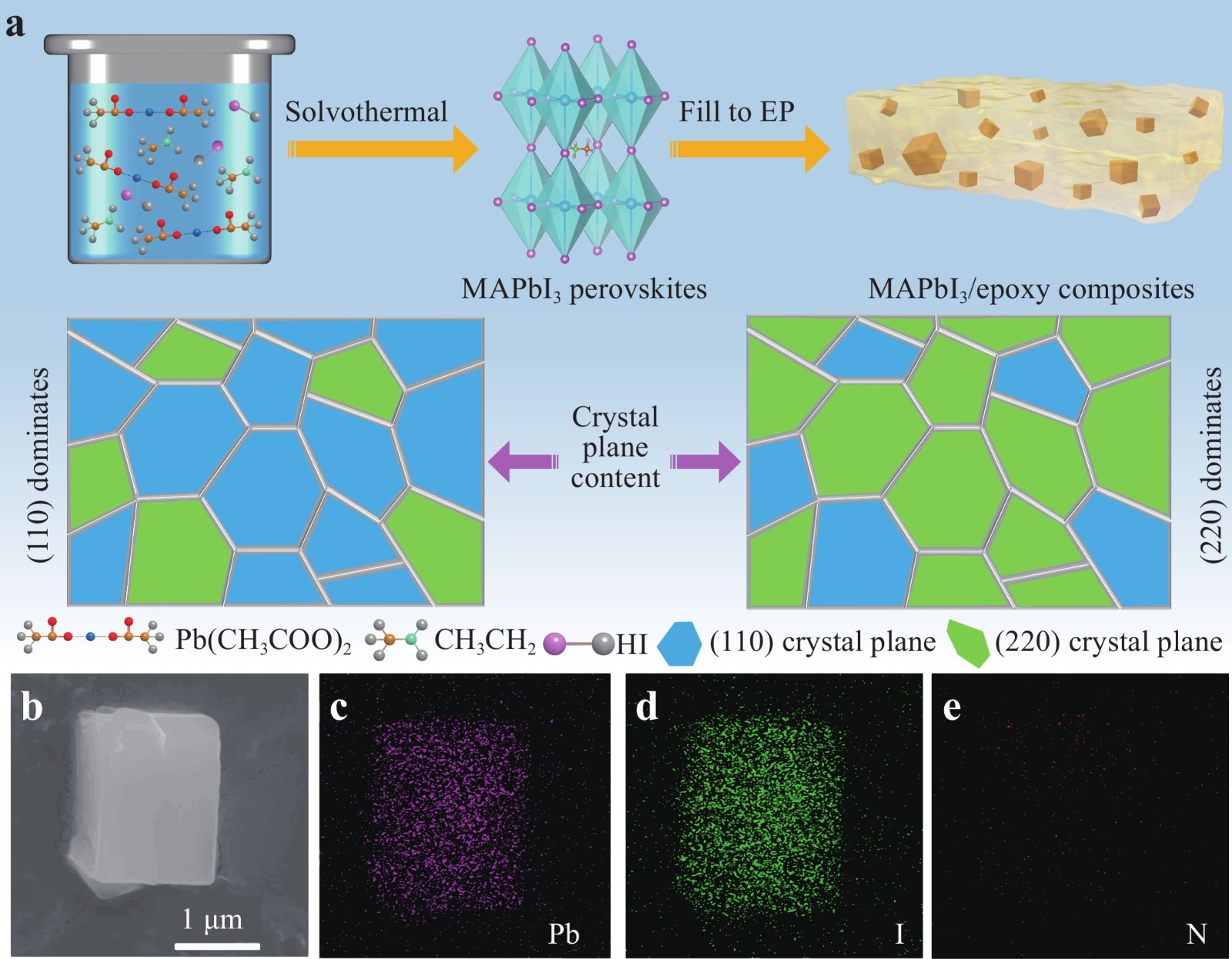

MAPbI3 microcubic crystals were directly synthesised by a facile one-step solvothermal process and then mixed with epoxy to fabricate MAPbI3/epoxy composites (Fig. 1a). To understand the correlation between the reaction time (Treaction) and crystal structure of MAPbI3, a series of reaction times (i.e. 0.5, 1.0, 1.5, 2.0, and 2.5 h) were used. The reaction time was found to play a considerable role in tailoring the crystal planes of the MAPbI3 microcubic crystals. Prolongation of the reaction time had the effect of increasing the content ratio of the (110) crystal plane to the (220) crystal plane, as shown in Fig. 1a. As shown in Fig. 1b−e, the SEM (scanning electron microscope) and corresponding EDS (energy dispersive spectrometry) images of the MAPbI3 microcubic crystals demonstrate an even and dense distribution of the elements Pb and I, together with a sparse distribution of the element N of MAPbI3.

Fig. 1 Design scheme and morphology characterisation. a Schematic illustration of the MAPbI3 microcubic crystals and the MAPbI3/epoxy composites. b SEM image of MAPbI3. c−e EDS mapping of Pb, I, and N, respectively.

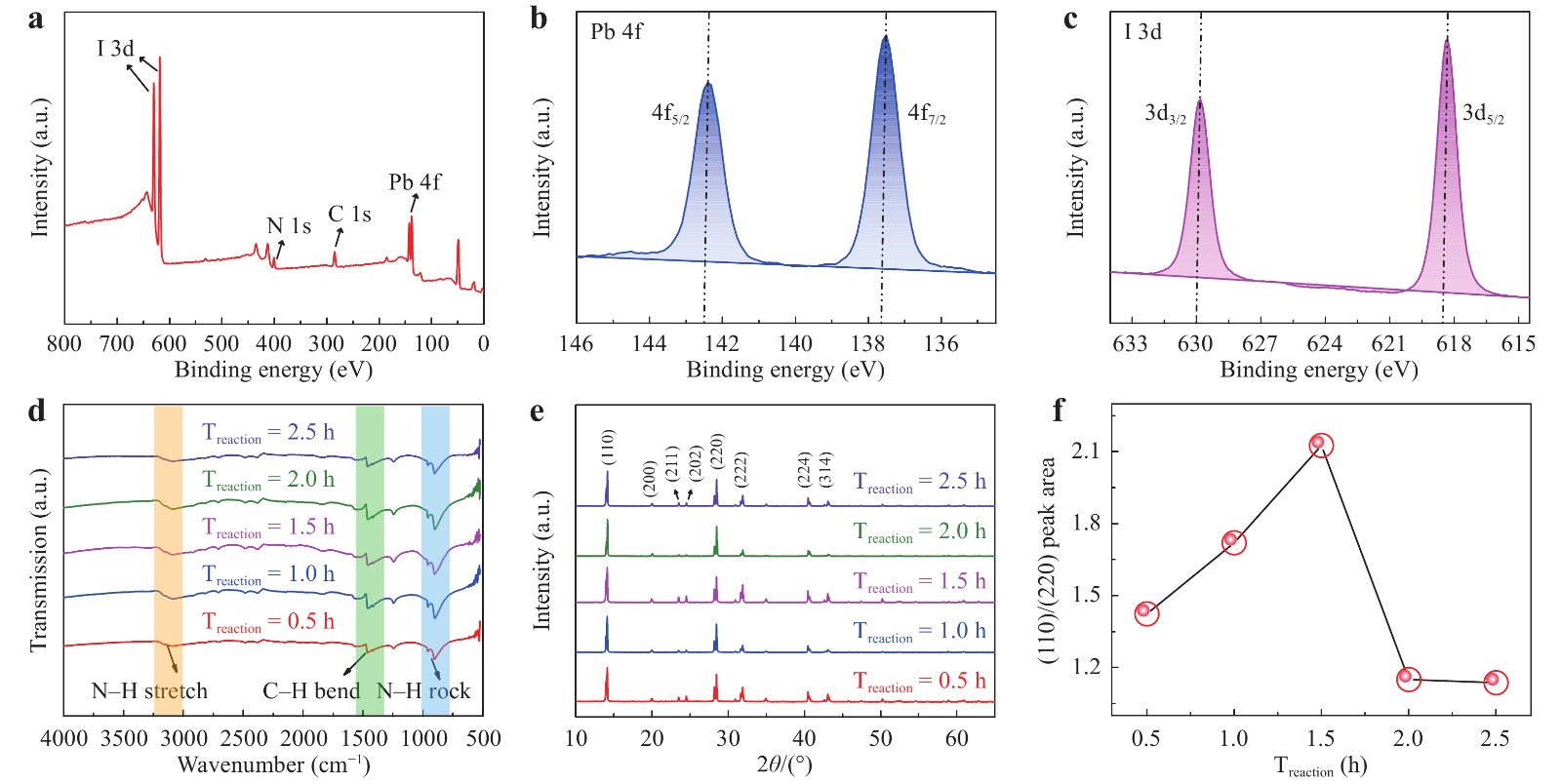

The surface composition and chemical states of the MAPbI3 microcubic crystals were probed by X-ray photoelectron spectroscopy (XPS). The XPS survey spectrum shown in Fig. 2a indicates the presence of C, N, Pb, and I in a representative MAPbI3 microcubic crystal. The corresponding high-resolution Pb 4f spectrum (Fig. 2b) presents two peaks at 137.6 eV and 142.4 eV, which are attributed to Pb 4f7/2 and Pb 4f5/2, respectively22. In addition, the high-resolution I 3d spectrum (Fig. 2c) has two peaks located at 618.4 eV and 629.9 eV, ascribed to I 3d5/2 and I 3d3/2, respectively23. These results revealed that the MAPbI3 microcubic crystals were successfully synthesised.

Fig. 2 Structural characterisation of the MAPbI3 microcubic crystals. a XPS survey spectrum. b Pb 4f, and c I 3d high-resolution spectra. d FTIR spectra. e XRD patterns. f Peak area ratio of the (110) plane to the (220) plane vs. reaction time.

Fourier-transform infrared spectroscopy (FTIR) was used to determine the molecular structures of the MAPbI3 microcubic crystals synthesised with different reaction times, as shown in Fig. 2d. The series of bands was identified as follows: (1) the band at 3132 cm−1 is attributed to the N-H symmetric stretching mode, (2) the band at 1577 cm−1 represents the C-H bending mode, and (3) the band at 911 cm−1 represents the N-H rocking mode24. These bands were not noticeably dependent on the reaction time, indicating that the molecular structures of the MAPbI3 microcubic crystals prepared using different reaction times were almost the same.

The phase structures of MAPbI3 microcubic crystals were investigated using powder X-ray diffraction (XRD). The XRD patterns of MAPbI3 microcubic crystals synthesised with reaction times of 0.5, 1.0, 1.5, 2.0, 2.5 h are shown in Fig. 2e. The diffraction peaks at 14.2°, 20.1°, 23.5°, 24.2°, 28.5°, 31.8°, 40.5°, and 43.1° correspond to the (110), (200), (211), (202), (220), (222), (224), and (314) planes of MAPbI3 perovskite (tetragonal, space group=I4/mcm, a=b=8.8743 Å, c =12.6708 Å), which is consistent with previous reports24. In addition, no diffraction peaks of other impurities such as PbI2 were observed, indicating that the MAPbI3 microcubic crystals prepared by the one-step solvothermal method are very pure.

Furthermore, the ratios of the peak areas of the (110) and (220) planes were compared, as shown in Fig. 2f, and these results show that the major crystal planes of the MAPbI3 microcubic crystals vary with the reaction time. The ratio of the peak area of the (110) plane to that of the (220) plane increases with the reaction time from 0.5 h to 1.5 h, suggesting that the (110) plane is the dominant crystal plane in the MAPbI3 microcubic crystal25,26. However, a further increase in the reaction time to 2.5 h causes the peak of the (110) plane to become relatively less intense than that of the (220) plane. The results suggest that the reaction time plays a critical role in regulating the crystal planes of the MAPbI3 microcubic crystals.

The HRTEM images (Fig. S1) further confirmed that the MAPbI3 microcubic crystals grew preferentially along the (110) and (220) planes27. The FWHM of the (110) crystal plane reached its maximum value (Fig. S2) for a reaction time of 1.5 h, and the mean particle size of the MAPbI3 microcubic crystals, as shown in the SEM image (Fig. S3), was measured as approximately 0.71 μm.

-

The gamma-ray shielding performance of the MAPbI3/epoxy composites was explored by conducting narrow beam measurements using Am-241 as a radiation source of photons with an energy of 59.5 keV. During the measurement, the samples were placed in the same position between the collimator and detector. A NaI (Tl) scintillation detector was employed to probe the intensity of gamma rays attenuated by the shielding materials.

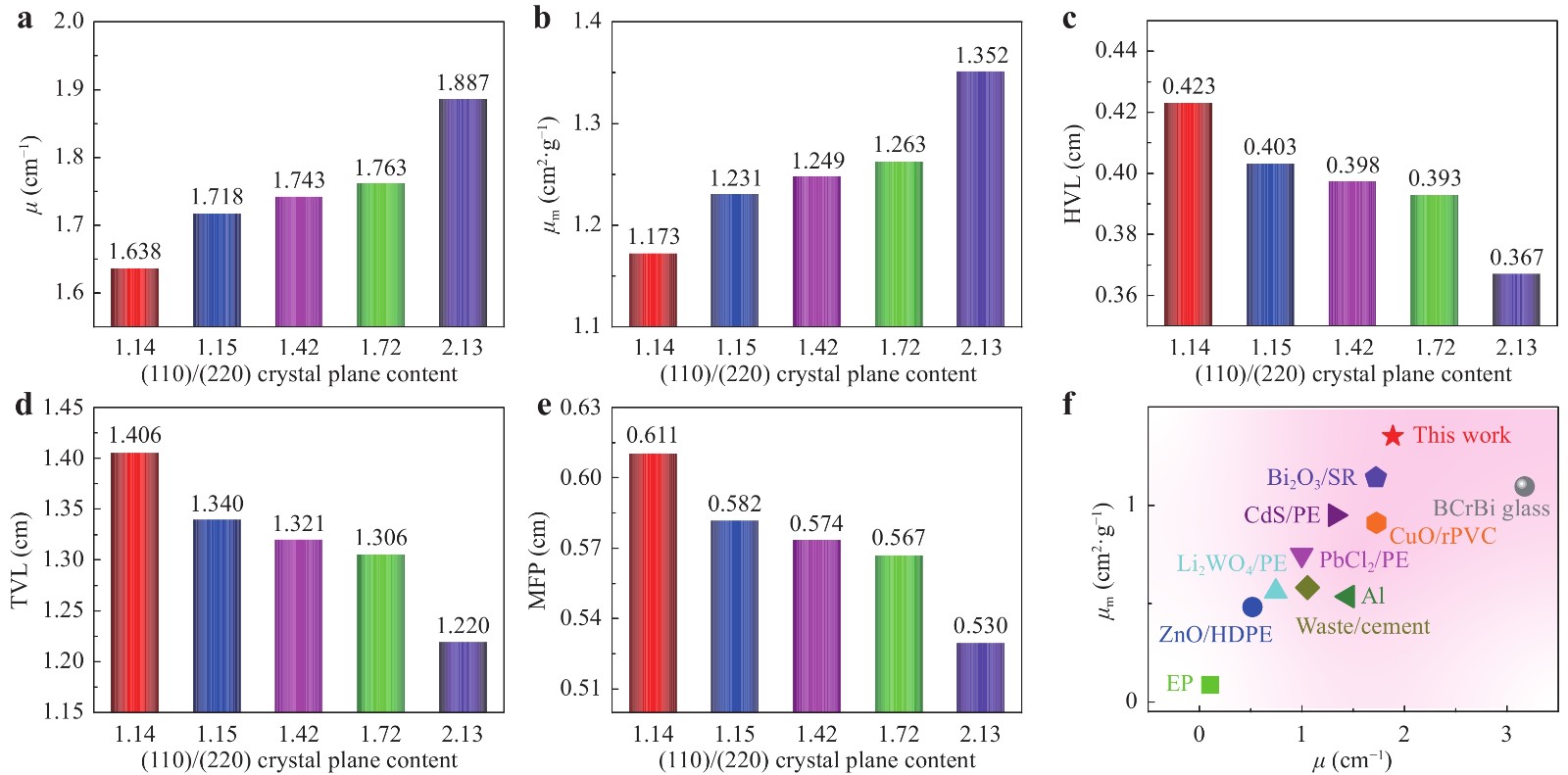

The linear attenuation coefficients of the MAPbI3/epoxy composites were measured and calculated using the Beer-Lambert law28. As shown in Fig. 3a, the μ values of the MAPbI3/epoxy composites were 1.638, 1.718, 1.743, 1.763, and 1.887 cm−1, respectively, depending on the peak area ratios of the (110) plane to the (220) plane. The value of μ increased as this peak area ratio increased. This finding suggests that the high proportion of the (110) crystal plane contributes to the remarkable performance of MAPbI3/epoxy composites. The dependence of the transmission (I/I0) on the sample thickness is listed in Table S1 for all samples.

Fig. 3 Dependence of the gamma-ray shielding performance of the MAPbI3/epoxy composites on the (110/220) crystal plane content. a Linear attenuation coefficient. b Mass attenuation coefficient. c Half value layer. d Tenth value layer. e Mean free path. f μ and μm of some commonly used materials reported in recent years.

As shown in Fig. 3b, similarly, the mass attenuation coefficients of the MAPbI3/epoxy composites are dependent on the peak area ratios of the (110) plane to the (220) plane. The maximum mass attenuation coefficient was 1.352 cm2 g−1, which corresponds to a ratio of 2.13. This phenomenon again reveals that a high proportion of the (110) crystal plane is beneficial for the shielding performance of the MAPbI3/epoxy composites because it facilitates collision with photons. Therefore, regulating the crystal planes of MAPbI3 microcubic crystals can significantly enhance their shielding abilities. The μ values (0.106 cm−1) and μm (0.087 cm2 g−1) of the pure epoxy are much lower than those of the MAPbI3/epoxy composites, indicating that the introduction of MAPbI3 can significantly improve the gamma-ray shielding performance of the epoxy.

In contrast, the HVL (half value layer), TVL (tenth value layer), and MFP (mean free path) of the MAPbI3/epoxy composites decreased as the peak area ratio of the (110) plane to the (220) plane increased (Fig. 3c−e). The minimum values of HVL, TVL, and MFP were 0.367, 1.220, and 0.530 cm, respectively, corresponding to a ratio of 2.13. The smaller the HVL and TVL, the thinner the MAPbI3/epoxy composite samples with substantial ability to attenuate gamma rays29,30. For example, MAPbI3/epoxy composite samples with a thickness of 36.7 mm of can attenuate half of the gamma rays with an energy of 59.5 keV, whereas MAPbI3/epoxy composites with a thickness of 1.220 cm can attenuate as much as 90% of gamma rays. In addition, a smaller MFP indicates an increased probability of collision between the photons and MAPbI3/epoxy composites in a certain volume31. In summary, these findings further confirm that the high shielding performance of MAPbI3/epoxy composites is mainly attributed to the predominance of the (110) plane.

The μ and μm values of some commonly used shielding materials are shown in Fig. 3f32-39. As can be seen, the current MAPbI3/epoxy composites have superior gamma ray (59.5 keV) shielding ability, as indicated by their large μ and μm values relative to most of the commonly used shielding materials. The MAPbI3/epoxy composites have higher μ values than most of those reported to date, indicating that the MAPbI3/epoxy composites have a strong ability to attenuate gamma rays. Furthermore, the MAPbI3/epoxy composites not only have excellent radiation attenuation ability but also have higher μm values. A higher μm value indicates that the MAPbI3/epoxy composites have low density and lightweight characteristics, which make them suitable for a wider range of applications.

The gamma-ray shielding performance of the MAPbI3/epoxy composites against Cs-137 (661 keV) and Co-60 (1250 keV) are presented in Table S2-S3. The radiation shielding performance of the MAPbI3/epoxy composites is related to the photon energy of the gamma rays in that an increase in the photon energy lowers μ and μm. Furthermore, at higher photon energies, the crystal plane engineering strategy could also be successfully used to regulate the gamma-ray shielding performance.

-

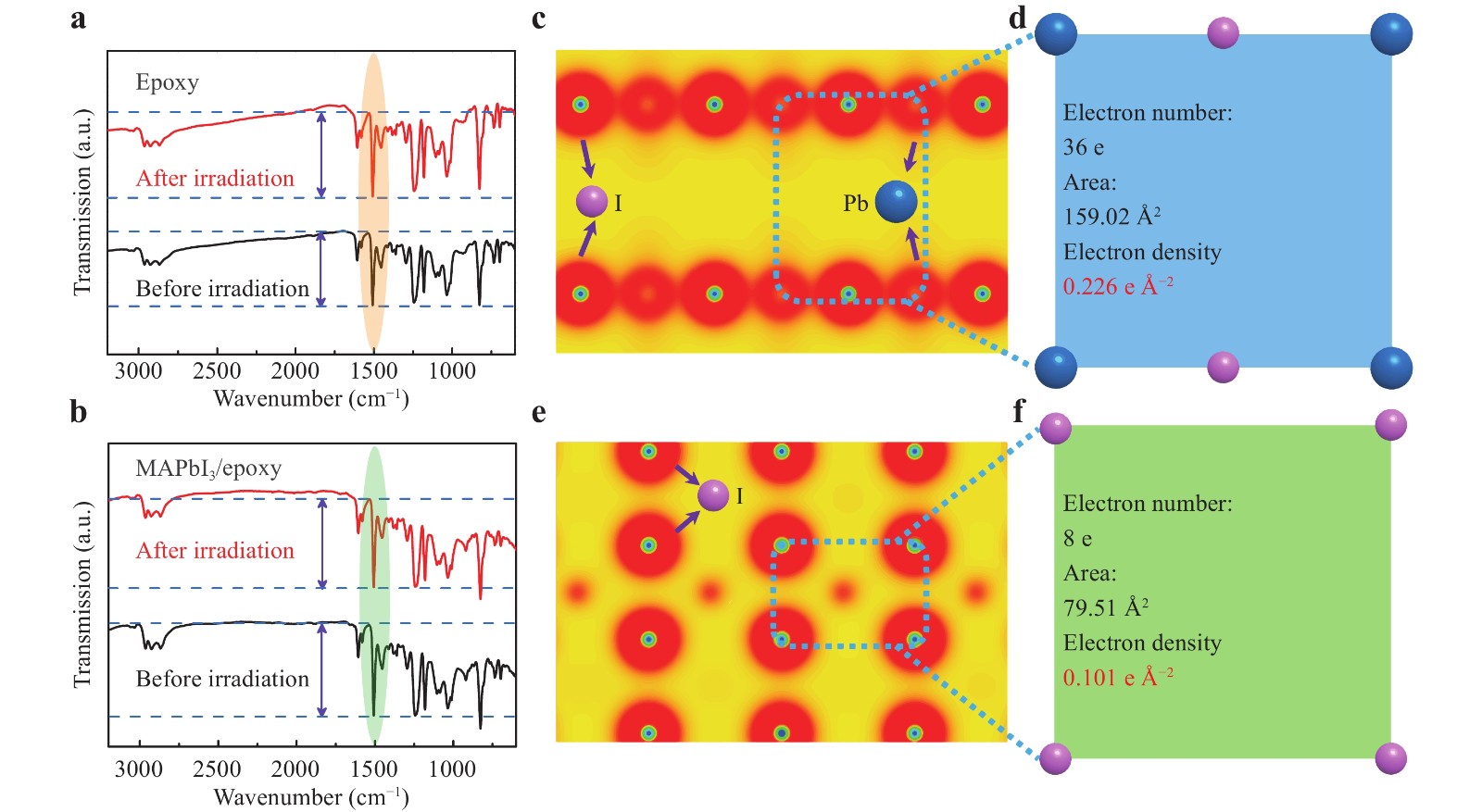

High-dose gamma-ray irradiation experiments on epoxy and MAPbI3/epoxy composites were conducted to examine the transmission behaviour of incident gamma rays in the materials. The FTIR spectra (Fig.4a, b) show that the intensity of the characteristic peaks of the epoxy at 1610, 1508, and 1294 cm−1 increased significantly after high-dose irradiation, whereas the corresponding characteristic peaks of the MAPbI3/epoxy composites underwent no obvious changes. This phenomenon indicates that the MAPbI3/epoxy composites have excellent structural stability when exposed to high-dose irradiation.

Fig. 4 FTIR spectra of a epoxy and b MAPbI3/epoxy composites before and after high dose irradiation. Electron localization functions of the c (110) and e (220) planes, and corresponding electron density values of the d (110) and f (220) planes.

To illustrate the modulation effects of the different crystal planes on the gamma-ray shielding ability, the electron localisation functions40,41 of the (110) and (220) planes were simulated using density functional theory (DFT) and the code of the Vienna ab initio simulation package (VASP)42. As shown in Fig. 4c, e, the electron localisation functions show that the electron density of the (110) plane originates from Pb and I in the ratio of one Pb atom to two I atoms. In contrast, the electron density of the (220) plane originated only from the element I. These results suggest that the electron arrangement of the (110) plane is more compact than that of the (220) plane.

To estimate the electron density of the (110) and (220) planes, the area demarcated by the blue dotted line was selected. As shown in Fig. 4d, f, the electron density of the (110) plane is 0.226 e Å−2, which is larger than that of the (220) plane (0.101 e Å−2), suggesting that the (110) plane provides more electrons for the incident photons to collide with. This indicates that the (110) plane can effectively attenuate the intensity of incident gamma rays. These findings reveal that crystal plane engineering is an effective strategy for the design of MAPbI3/epoxy composites with excellent gamma-ray shielding performance. In addition to this, we measured the density of each MAPbI3/epoxy composite, and the corresponding values are listed in Table S4. The densities of the MAPbI3/epoxy composites was not influenced significantly by the content ratio of the (110) crystal plane to the (220) crystal plane, indicating that the crystal plane engineering strategy did not affect the gamma-ray shielding performance of MAPbI3/epoxy composites by changing the material density.

-

Based on the above results, we propose a mechanism whereby crystal plane engineering regulates the gamma-ray shielding performance of MAPbI3/epoxy composites, as shown in Fig. 5. When gamma rays (59.5 keV) reach the MAPbI3/epoxy composites, interaction between the incident gamma ray and the (110) plane or (220) plane induces the photoelectric effect. As a result, electrons are emitted, for which most of the energy of the gamma ray is attenuated to overcome the electron binding energy in the L shell of Pb and the K shell of I43.

Fig. 5 Proposed mechanism of the enhanced gamma-ray shielding performance of the MAPbI3/epoxy composites.

As mentioned above, the electron density of the (110) plane is higher than that of the (220) plane. Therefore, it could be deduced that the attenuation of the incident gamma ray by the (110) plane is greater than that of the (220) plane because of the more effective collisions between the incident photons and extranuclear electrons. In other words, MAPbI3/epoxy composites with more (110) planes exhibited improved gamma-ray shielding performance. In summary, crystal plane engineering is a useful strategy for the preparation of MAPbI3/epoxy composites with the aim of enhancing the gamma-ray shielding performance by increasing the electron density.

-

In summary, based on the crystal plane engineering strategy, we prepared MAPbI3 microcubic crystals with controllable electron density using a simple one-step solvothermal method. The experimental findings suggested that the gamma-ray shielding performance of MAPbI3/epoxy composites is strongly correlated with the ratio of the peak area of the (110) plane to that of the (220) plane. The MAPbI3/epoxy composite corresponding to the highest ratio of 2.13, exhibited a high linear attenuation coefficient (1.887 cm−1) and a high mass attenuation coefficient (1.352 cm2 g−1). Crystal plane engineering was shown to be an effective strategy to effectively regulate the electron density of MAPbI3/epoxy composites, thereby controlling the possibility of collision between the incident gamma rays and MAPbI3/epoxy composites. The present work provides essential guidelines for the design and synthesis of high-efficiency radiation-shielding materials.

-

All chemicals were of analytical grade and used without further purification. Lead acetate (Pb(CH3COO)2, 99.5%) and hydroiodic acid (HI, 48%) were acquired from Aladdin Biochemical Technology Co. Ltd. (China). Methylamine (CH3NH2, 99%) and isopropyl alcohol ((CH3)2CHOH, 99.7%) were obtained from China Chemical Reagent Co., Ltd. Epoxy K-9761 was purchased from Guangdong Hengda New Material Technology Co. Ltd. (China).

-

A solvothermal method was used to synthesise the MAPbI3 microcubic crystals. Pb(CH3COO)2 powder (60 mg) and CH3NH2 (30 mL) were added to a mixture of HI (1 mL) and (CH3)2CHOH (30 mL) under stirring for 30 min, after which the mixture was transferred to a 100 mL Teflon lined steel autoclave for the synthesis at 120 ℃ for a period of time (0.5, 1.0, 1.5, 2.0, 2.5 h). MAPbI3 microcubic crystals were recovered by centrifugation and dried at 60 ℃ for 12 h.

-

MAPbI3 powder (20 wt. %) and epoxy resin were mixed by stirring for 5 min. The resulting mixture was poured into prefabricated PTFE moulds and left overnight at room temperature (22 ± 2 ℃) for curing.

-

The crystallinity and phase purity of the samples were measured using an Empyrean X-ray diffractometer (PANalytical) with Cu Kα radiation (λ= 1.541 Å) at a scanning rate of 6o min-1 in the region of 2θ=10−80o. The particle size and morphology were determined using field emission scanning electron microscopy (FESEM, Carl Zeiss Company) with an accelerating voltage of 20 kV, and SEM-EDS was carried out using a Teneo volume scope. Fourier-transform infrared (FTIR) spectra were measured using a Thermo Nicolet iS50 spectrometer (Thermo Fisher Scientific). X-ray photoelectron spectroscopy (XPS) measurements were performed using a Thermo 250XI spectrometer (Thermo Fay). TEM and HRTEM measurements were performed using a Tecnai G2 F20 transmission electron microscope (FEI). Gamma irradiation experiments were carried out using the Co-60 radiation resource at the Heilongjiang Institute of Atomic Energy, China. The gamma-ray shielding performance of the MAPbI3/epoxy composites was evaluated using an Am-241 source, and the transmittance was measured using an HD-2000 gamma-ray detector.

-

Our ab initio density functional theory calculations used projective enhancement waves to describe the core electrons and used the Perdew-Burke-Ernzerhof functional implemented in code of the VASP42 for generalised gradient approximation. We set an energy cutoff of 500 eV for the plane wave bases of all the systems to ensure an equal footing. All the calculations were performed at a convergence threshold of 10−4 eV. The energy relaxation at each strain step continued until the force on all the atoms converged to less than 0.02 eV Å−1. The van der Waals interactions (vdW) were calculated using the DFT-D3 method. The stable (110) and (220) surfaces of MAPbI3 were simulated using a slab model.

-

In a narrow beam measurement, the attenuated intensity of a gamma ray is a function of the thickness, expressed by the following equation28:

$$ I = {I_0}\exp \left( { - \mu x} \right) $$ (1) where I0 is the intensity of the incident gamma rays, I is the intensity of the gamma rays passing through the shielding material, μ is the linear attenuation coefficient of the shielding material, and x is the thickness of the shielding material. μ represents the total interaction probability per unit thickness of the shielding material. During the experiments, the initial intensity and attenuated intensity of the gamma ray were measured, and then μ was calculated based on Eq. 1.

The mass attenuation coefficient is another useful parameter for evaluating the radiation-shielding performance of materials. Usually, μm is more meaningful than μ for the assessment of radiation-shielding materials. μm was calculated using Eq. 244:

$$ {\mu _m} = \mu /\rho = \ln \left( {{I_0}/I} \right)/\rho x = \ln \left( {{I_0}/I} \right)/{t_m} = m\ln \left( {{I_0}/I} \right)/A $$ (2) where ρ is the density of the shielding material (g cm−3), tm is the mass per unit area (g cm−2), also known as the sample mass thickness, m is the mass of the material, and A is the surface area of the shielding material.

The half value layer (HVL) is a significant parameter. It is defined as the absorber thickness required to reduce the incident gamma-ray intensity to 50%. The HVL is calculated using Eq. 329:

$$ {\rm{HVL}} = {{\rm{X}}_{1/2}} = \left( {\ln 2} \right)/\mu $$ (3) where X1/2 is the thickness of the shielding material required for the photon intensity to decay by half.

Similarly, the tenth layer (TVL) is defined as the absorber thickness required to lower the incident gamma-ray intensity to 10%. It is calculated using Eq. 430:

$$ {\rm{TVL}} = {{\rm{X}}_{1/10}} = \left( {\ln 10} \right)/\mu $$ (4) where X1/10 represents the thickness of the shielding material required to attenuate the initial photon intensity by one-tenth.

Because the gamma rays interact with the shielding materials, the average distance that a photon travels between two successive interactions is known as the mean free path (MFP). The MFP is also referred to as the relaxation length (λ) and is calculated using Eq. 545:

$$ {\rm{MFP}} = \lambda = 1/\mu $$ (5) -

Financial support provided by the National Natural Science Foundation of China (Grant No. U2067216), and NSAF (Grant No. U2130109) is greatly appreciated.

Crystal plane engineering of MAPbI3 in epoxy-based materials for superior gamma-ray shielding performance

- Light: Advanced Manufacturing 3, Article number: (2022)

- Received: 24 June 2021

- Revised: 03 November 2022

- Accepted: 03 November 2022 Published online: 08 December 2022

doi: https://doi.org/10.37188/lam.2022.051

Abstract: The rapid development of the aerospace and nuclear industries is accompanied by increased exposure to high-energy ionising radiation. Thus, the performance of radiation shielding materials needs to be improved to extend the service life of detectors and ensure the safety of personnel. The development of novel lightweight materials with high electron density has therefore become urgent to alleviate radiation risks. In this work, new MAPbI3/epoxy (CH3NH3PbI3/epoxy) composites were prepared via a crystal plane engineering strategy. These composites delivered excellent radiation shielding performance against 59.5 keV gamma rays. A high linear attenuation coefficient (1.887 cm−1) and mass attenuation coefficient (1.352 cm2 g−1) were achieved for a representative MAPbI3/epoxy composite, which was 10 times higher than that of the epoxy. Theoretical calculations indicate that the electron density of MAPbI3/epoxy composites significantly increases when the content ratio of the (110) plane in MAPbI3 increases. As a result, the chances of collision between the incident gamma rays and electrons in the MAPbI3/epoxy composites were enhanced. The present work provides a novel strategy for designing and developing high-efficiency radiation shielding materials.

Research Summary

Radiation shielding: MAPbI3/epoxy composites exhibit superior performance

A material that regulates radiation shielding performance through a crystal plane engineering strategy shows promise for mitigating radiation risks in the aerospace and nuclear industries. Organic-inorganic hybrid perovskites are new candidate materials in the field of radiation shielding because the heavy atoms of perovskite materials and scintillation characteristics are conducive to the interaction with photons. Yang Li, Wei Qin and Xiaohong Wu from Harbin Institute of Technology and colleagues now report development of MAPbI3/epoxy composites prepared via a crystal plane engineering strategy. These composites delivered excellent radiation shielding performance against gamma rays and was 10 times higher than the epoxy. MAPbI3 with altered crystal planes plays a determining role in the gamma-ray shielding performance of the corresponding composites. Crystal plane engineering was shown to be an effective strategy to regulate the electron density of MAPbI3/epoxy composites, thereby controlling the possibility of collision between the incident gamma rays and MAPbI3/epoxy composites. The team's work provides a novel strategy for designing and developing high-efficiency radiation shielding materials.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article′s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article′s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

DownLoad:

DownLoad: