View by Category

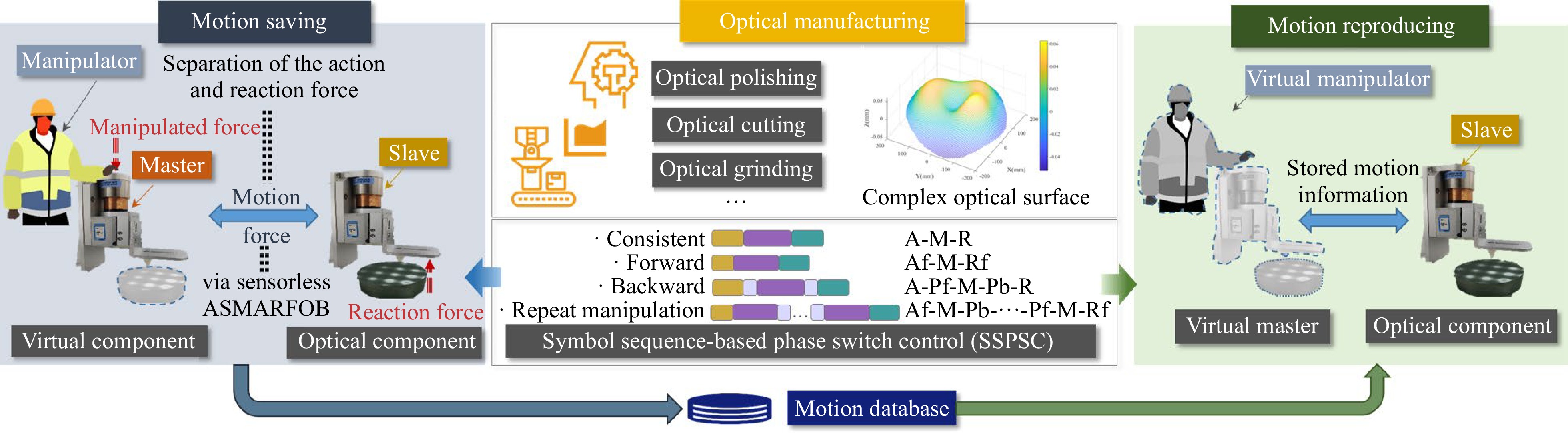

Implementation of robot-based motion control in optical machining demonstrably enhances the machining quality. The introduction of motion-copying method enables learning and replicating manipulation from experienced technicians. Nevertheless, the location uncertainties of objects and frequent switching of manipulated spaces in practical applications impose constraints on their further advancement. To address this issue, a motion-copying system with a symbol-sequence-based phase switch control (SSPSC) scheme was developed by transferring the operating skills and intelligence of technicians to mechanisms. The manipulation process is decomposed, symbolised, rearranged, and reproduced according to the manufacturing characteristics regardless of the change in object location. A force-sensorless adaptive sliding-mode-assisted reaction force observer (ASMARFOB), wherein a novel dual-layer adaptive law was designed for high-performance fine force sensing, was established. The uniformly ultimate boundedness (UUB) of the ASMARFOB is guaranteed based on the Lyapunov stability theory, and the switching stability of the SSPSC was examined. Validation simulations and experiments demonstrated that the proposed method enables better motion reproduction with high consistency and adaptability. The findings of this study can provide effective theoretical and practical guidance for high-precision intelligent optical manufacturing.

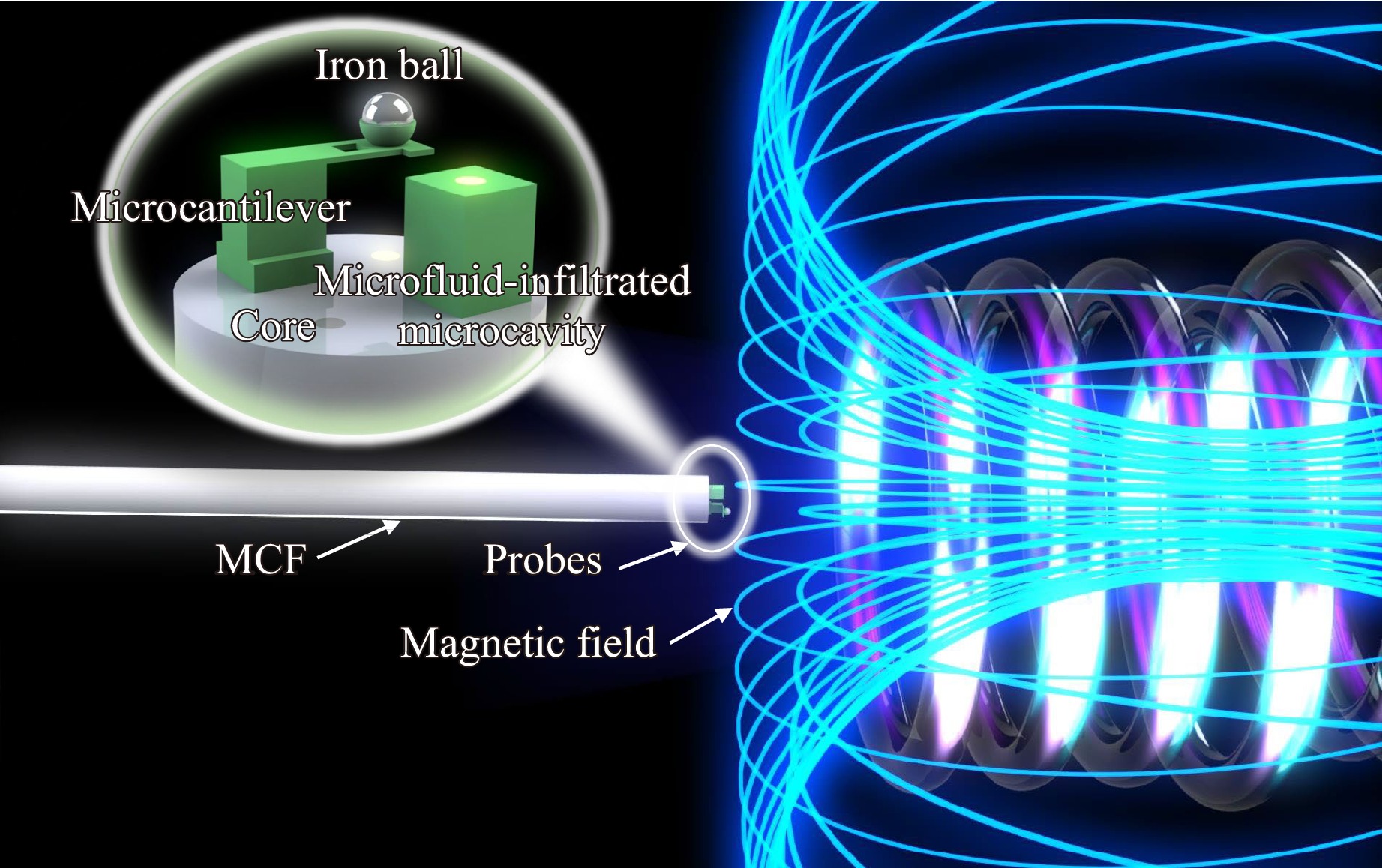

Miniaturized fiber-optic magnetic field sensors have attracted considerable interest owing to their superiorities in anti-electromagnetic interference and compactness. However, the intrinsic thermodynamic properties of the material make temperature cross-sensitivity a challenging problem in terms of sensing accuracy and reliability. In this study, an ultracompact multicore fiber (MCF) tip sensor was designed to discriminatively measure the magnetic field and temperature, which was subsequently evaluated experimentally. The novel 3D printed sensing component consists of a bowl-shaped microcantilever and a polymer microfluid-infiltrated microcavity on the end-facet of an MCF, acting as two miniaturized Fabry-Perot interferometers. The magnetic sensitivity of the microcantilever was implemented by incorporating an iron micro ball into the microcantilever, and the microfluid-infiltrated microcavity enhanced the capability of highly sensitive temperature sensing. Using this tiny fiber-facet device in the two channels of an MCF allows discriminative measurements of the magnetic field and temperature by determining the sensitivity coefficient matrix of two parameters. The device exhibited a high magnetic field intensity sensitivity, approximately 1805.6 pm/mT with a fast response time of ~ 213 ms and a high temperature sensitivity of 160.3 pm/℃. Moreover, the sensor had a low condition number of 11.28, indicating high reliability in two-parameter measurements. The proposed 3D printed MCF-tip probes, which detect multiple signals through multiple channels within a single fiber, can provide an ultracompact, sensitive, and reliable scheme for discriminative measurements. The bowl-shaped microcantilever also provides a useful platform for incorporating microstructures with functional materials, extending multi-parameter sensing scenarios and promoting the application of MCFs.

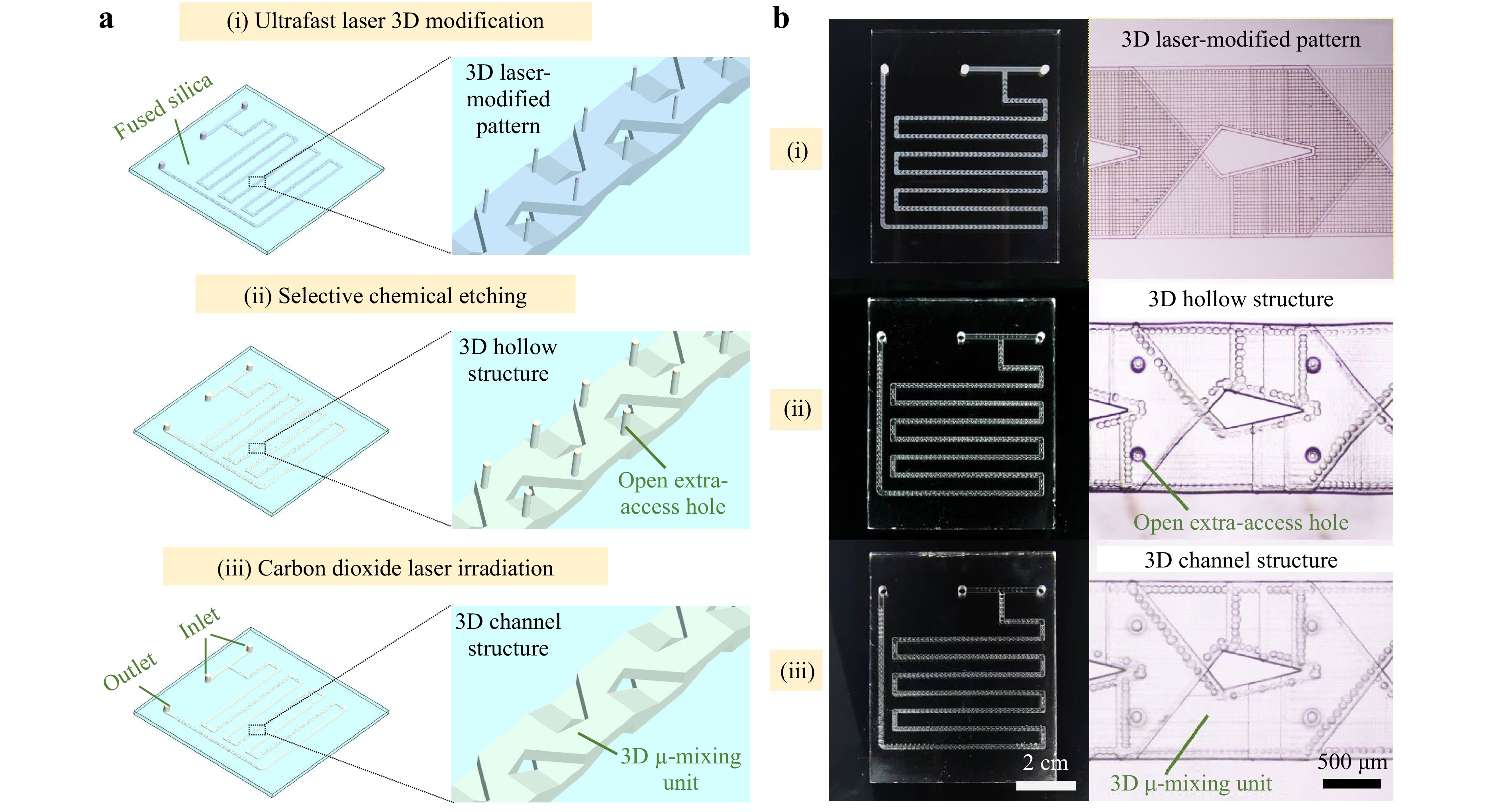

Large-scale, high-precision, and high-transparency microchannels hold great potential for developing high-performance continuous-flow photochemical reactions. We demonstrated ultrafast laser-enabled fabrication of three-dimensional microchannel reactors in ultraviolet (UV) grade fused silica which exhibit high transparency under the illumination of UV light sources of wavelengths well below 300 nm with excellent mixing efficiency. With the fabricated glass microchannel reactors, we demonstrated continuous-flow photochemical synthesis of vitamin D3 with UV LED array light sources.

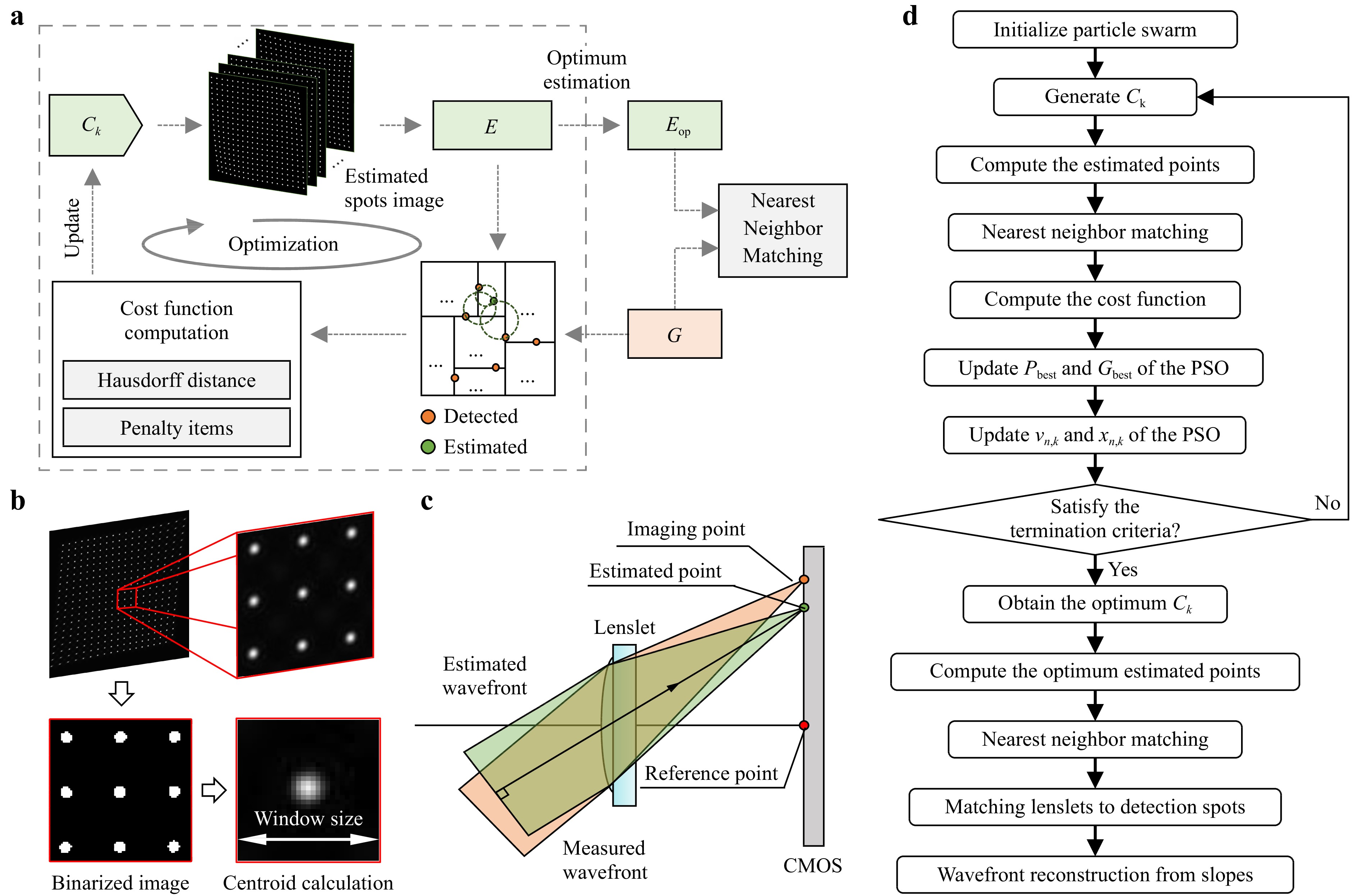

The Shack-Hartmann wavefront sensor (SHWS) is widely used for high-speed, precise, and stable wavefront measurements. However, conventional SHWSs encounter a limitation in that the focused spot from each microlens is restricted to a single microlens, leading to a limited dynamic range. Herein, we propose an adaptive spot matching (ASM)-based SHWS to extend the dynamic range. This approach involves seeking an incident wavefront that best matches the detected spot distribution by employing a Hausdorff-distance-based nearest-distance matching strategy. The ASM-SHWS enables comprehensive spot matching across the entire imaging plane without requiring initial spot correspondences. Furthermore, due to its global matching capability, ASM-SHWS can maintain its capacity even if a portion of the spots are missing. Experiments showed that the ASM-SHWS could measure a high-curvature spherical wavefront with a local slope of 204.97 mrad, despite a 12.5% absence of spots. This value exceeds that of the conventional SHWS by a factor of 14.81.

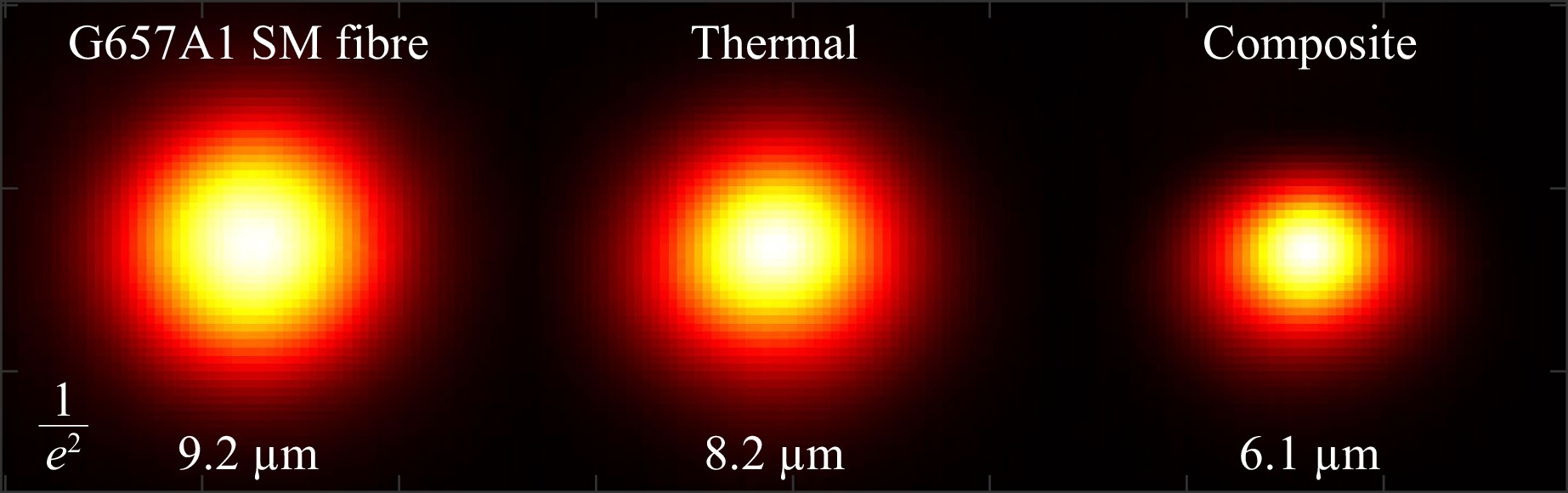

We demonstrate a novel, composite laser written 3D waveguide, fabricated in boro-aluminosilicate glass, with a refractive index contrast of 1.12 × 10−2. The waveguide is fabricated using a multi-pass approach which leverages the respective refractive index modification mechanisms of both the thermal and athermal inscription regimes. We present the study and optimisation of inscription parameters for maximising positive refractive index change and ultimately demonstrate a dramatic advancement on the state of the art of bend losses in laser-written waveguides. The 1.0 dB cm−1 bend loss cut-off radius is reduced from 10 mm to 4 mm, at a propagation wavelength of 1550 nm.

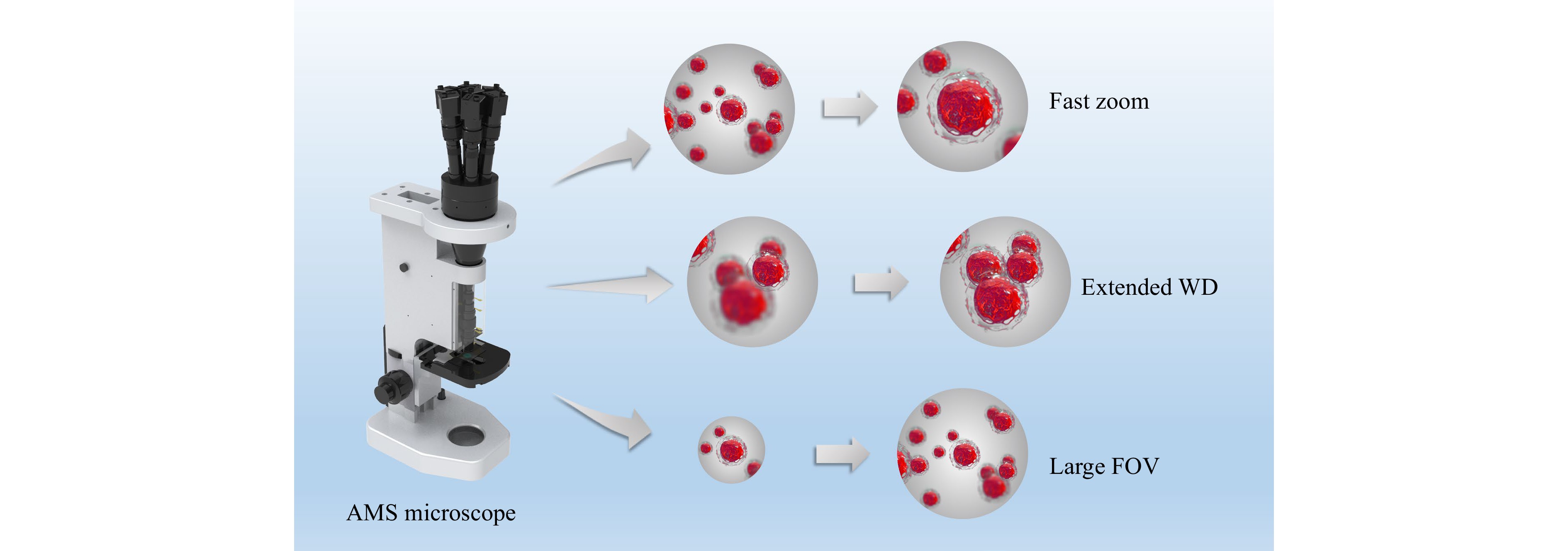

The field-of-view (FOV), depth of field, and resolution of conventional microscopes are constrained by each other; therefore, a zoom function is required. Traditional zoom methods lose real-time performance and have limited information throughput, severely limiting their application, especially in three-dimensional dynamic imaging and large-amount or large-size sample scanning. Here, an adaptive multiscale (AMS) imaging mechanism combining the benefits of liquid lenses and multiscale imaging techniques is proposed to realize the functions of fast zooming, wide working distance (WD) range and large FOV on a self-developed AMS microscope. The design principles were revealed. Moreover, a nonuniform-distortion-correction algorithm and a composite patching algorithm were designed to improve image quality. The continuous tunable magnification range of the AMS microscope is from 9× to 18×, with the corresponding FOV diameters and resolution ranging from 2.31 to 0.98 mm and from 161 to 287 line-pairs/mm, respectively. The extended WD range is 0.8 mm and the zoom response time is 38 ms. Experiments demonstrated the advantages of the proposed microscope in pathological sample scanning, thick-sample imaging, microfluidic process monitoring, and the observation of living microorganisms. The proposed microscope is the first step towards zoom multiscale imaging technology and is expected to be applied in life sciences, medical diagnosis, and industrial detection.

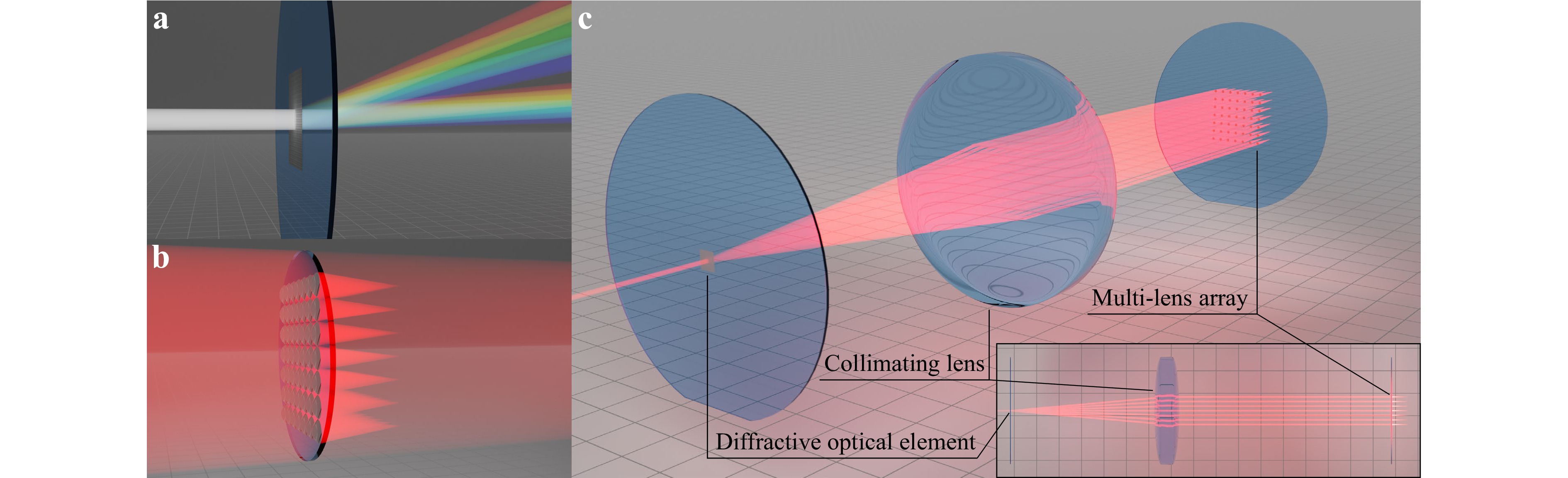

One of the challenges in the field of multi-photon 3D laser printing lies in further increasing the print speed in terms of voxels/s. Here, we present a setup based on a 7 × 7 focus array (rather than 3 × 3 in our previous work) and using a focus velocity of about 1 m/s (rather than 0.5 m/s in our previous work) at the diffraction limit (40×/NA1.4 microscope objective lens). Combined, this advance leads to a ten times increased print speed of about 108 voxels/s. We demonstrate polymer printing of a chiral metamaterial containing more than 1.7 × 1012 voxels as well as millions of printed microparticles for potential pharmaceutical applications. The critical high-quality micro-optical components of the setup, namely a diffractive optical element generating the 7 × 7 beamlets and a 7 × 7 lens array, are manufactured by using a commercial two-photon grayscale 3D laser printer.

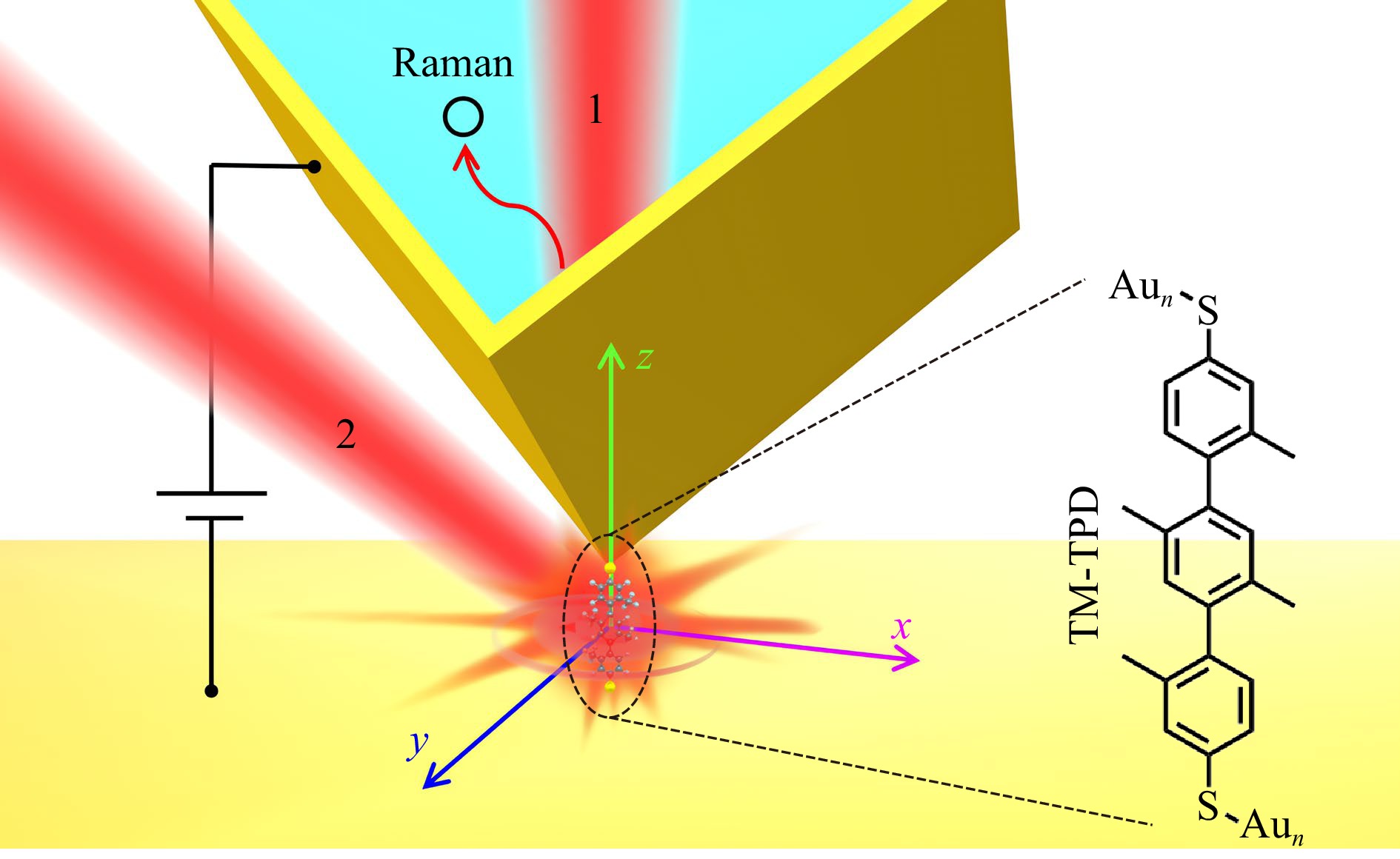

The role of molecular junctions in nanoelectronics is most often associated with electronic transport; however, their precise characterisation hinders their widespread development. The interaction of light with molecular junctions is a supplementary factor for the development of molecular switches, but it has rarely been addressed. The influence of light interaction with molecular junctions on the response of molecules in the near field was demonstrated by properly characterising the optical angular momentum at the junctions. Consequently, the molecular switching dynamics were observed in the Raman signatures of the conducting molecules. The illumination geometry and voltage applied to the junction were changed to demonstrate numerically and experimentally how the Raman intensity can be turned ON and OFF with a difference of nearly five orders of magnitude. These molecular-scale operations result from the combined interaction of a current-induced electronic rearrangement in the molecular junction and a plasmonically enhanced electromagnetic field near the tip of the junction. This study of the effect of optical angular momentum on the near field of the molecular junction shows significant potential for the development of molecular electronics.

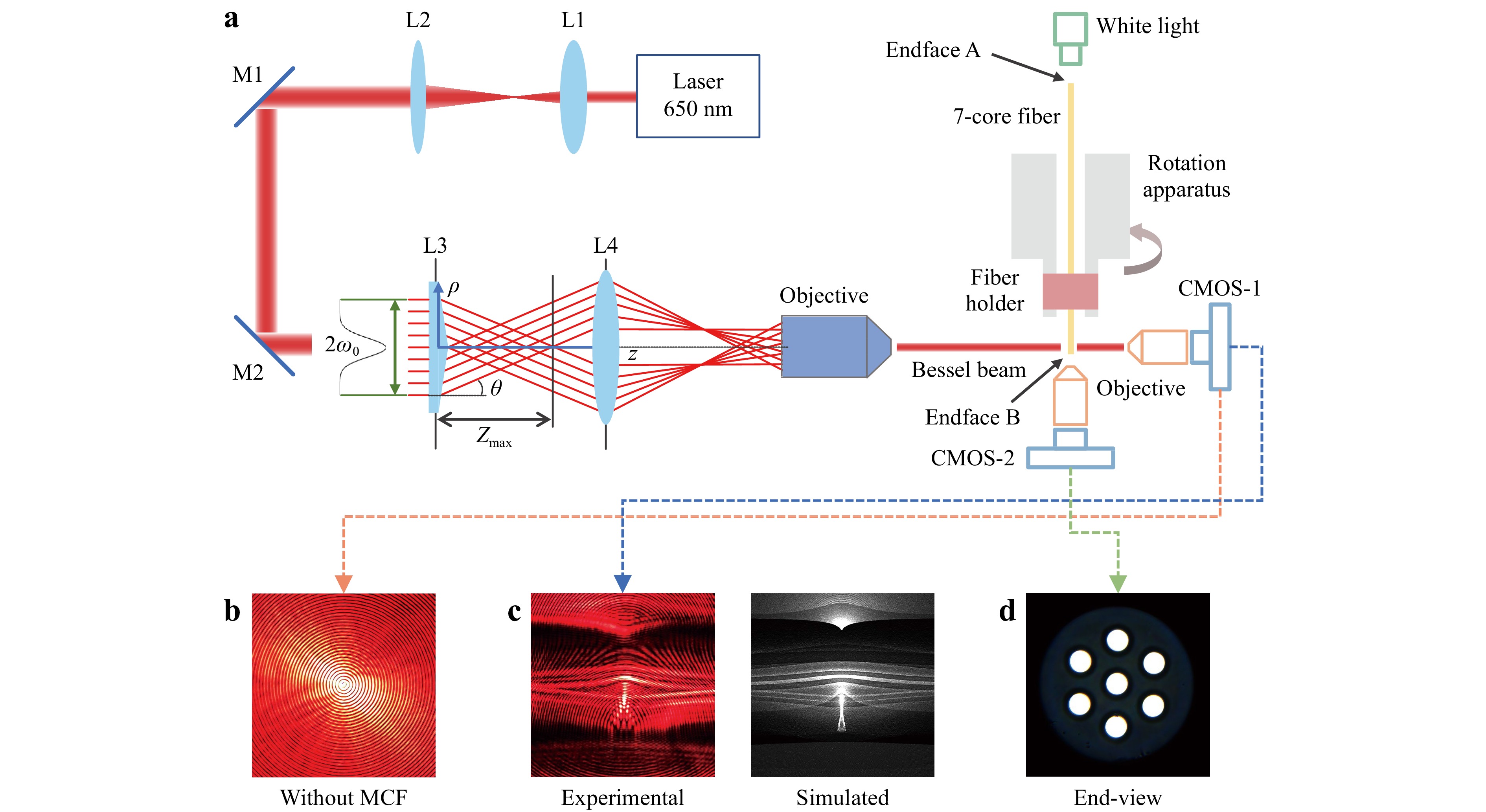

Accurate knowledge of the internal core distribution of multicore fibres (MCFs) is essential, given their widespread application, including in fibre splicing, bundle fan-in/fan-out, mode coupling, writing gratings, and fibre drawing. However, the extensive use of MCFs is restricted by the limited methods available to precisely measure the fibre core distribution, as the measurement accuracy determines the performance of the product. In this study, a side-view and nondestructive scheme based on Bessel beam illumination was proposed for measuring the internal core distribution of a seven-core fibre. Bessel beams offer a large focal length in a scattering medium, and exhibit a unique pattern when propagating in an off-axis medium with a spatially varying refractive index. The results revealed that a long focal length and unique pattern influence the image contrast in the case of Bessel beams, which differs from a typical Gaussian beam. Further, high-precision measurement of a seven-core fibre core distribution based on a Bessel beam was demonstrated using a digital correlation method. A deep learning approach was used to improve the measurement precision to 0.2° with an accuracy of 96.8%. The proposed side-view Bessel-beam-based method has the potential to handle more complex MCFs and photonic crystal fibres.

- First

- Prev

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- Next

- Last

- Total:9

- To

- Go

Email

Email RSS

RSS